Quartz Impurities Removal Process and Equipment

Shirley

Shirley

Nov 13, 2020

Nov 13, 2020

3090

3090

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

(Quartz ore)

Usually, quartz sand contains some impurity minerals (mainly mica minerals, feldspar minerals, iron-aluminum metal oxide minerals, etc.), and the mixing of these impurities greatly reduce the value of quartz sand and affect product quality.

Therefore, in order to meet the needs of industrial applications, it is necessary to remove impurities from quartz sand. Below, we'll learn more about the quartz sand impurities removal process and the required equipments.

01 Quartz Impurities Dissociation Process and Equipment

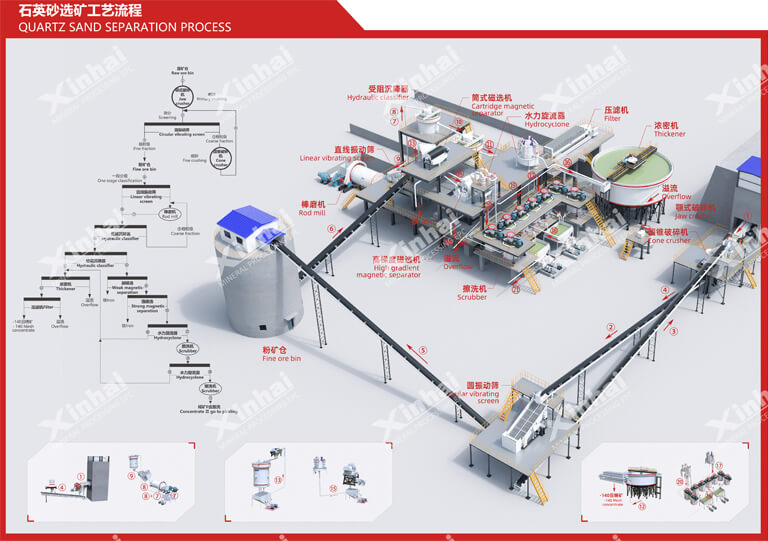

BackQuartz sand impurity dissociation process refers to a process to make impurities and minerals reach monomer dissociation state. It should grind natural quartz sandstone ore by crushing, grinding, and classifying operations and make impurities and minerals reach the monomer dissociation state. Then it an obtain raw material quartz sand particles that meet the requirements of particle size through classifying, and prepare for the subsequent quartz sand impurities removal operations.

Specific Process:

It can use a jaw crusher to crush the natural quartz sandstone ore into small pieces, and then wet grind these small pieces of quartz ore into finer-grained quartz particles using grinding equipment.

The wet grinding process used can not only eliminate the dust generated in the grinding process, but also make the quartz particles rub against each other, and promote the dissociation of impurities (such as iron oxides and hydroxides, etc.) attached to the quartz surface from the quartz particles .

Subsequently, the grinding products enter the classification operation, and the quartz sand that meets the particle size requirements can be used as the raw material for the next step of quartz sand impurities removal, and the coarse particles are returned to the grinding equipment for regrind.

Required Equipment:

Jaw crusher, wet rod mill, wet overflow ball mill, silica sand hydraulic classifier, spiral classifier

1

1

02 Quartz Impurities Removal Process and Equipment

BackThe quartz sand impurities removal process is to remove the mineral impurities in the quartz sand by scrubbing, desliming, magnetic separation, chute gravity separation, flotation, pickling or a combination of several methods to obtain the high-purity quartz sand with qualified particle size and impurity content.

(1) Scrubbing and Desliming

With the help of the mechanical force of the scrubber and the grinding and peeling force between the sand particles, the iron thin film, adhesive and muddy impurities on the surface of the quartz sand can be removed, and the undissociated mineral aggregates can be further crushed, and then further purified by the classification operation.

Equipment Needed:

High-efficiency agitation scrubber

(2) Magnetic Separation

Magnetic separation is one of the effective methods to remove iron-containing impurities in raw materials. Since the minerals such as hematite, limonite and biotite contained in the raw materials have weak magnetic properties, they can be selected when the magnetic field strength is above 8×105A/m (ampere/m) by using a wet-type strong magnetic separator.

For strong magnetic minerals such as magnetite, weak magnetic separators or medium magnetic separators can be used.

In order to further remove other small amounts of weakly magnetic minerals (such as hornblende, pyroxene and concatenation of magnetic minerals and quartz), we can use a high-gradient magnetic separator with a magnetic field strength greater than 12000 gauss for secondary magnetic separation.

Equipment Needed:

Magnetic separator

(3) Spiral Chute Gravity Separation Method

When the raw material contains a very small amount of heavy mineral impurities (such as zircon), because it is not magnetic and has a specific weight greater than quartz, we can use the spiral chute gravity separation method to effectively remove such heavy mineral impurities.

When the raw material rotates and slides along the spiral chute surface, various minerals will be separated under the dual action of gravity and centrifugal force according to their respective specific gravity. The greater the difference in the specific gravity of the minerals, the better the separation efficiency.

It is worth noting that the mineral morphology also has a certain influence on the sorting of the spiral chute, and flake minerals are easier to separate from granular minerals.

Therefore, when using the spiral chute to sort the raw quartz slurry, the sorted quartz sand can be divided into three parts: granular heavy mineral area, granular quartz sand area, flaky mineral area and light mineral area. While using the spiral chute to remove the heavy minerals in the quartz sand, it can also remove part of the flake mica minerals.

Equipment Needed:

Spiral chute

(4) Flotation Method

If there are many kinds of mica minerals in the raw materials, it is impossible to completely remove the impurities using only the spiral chute. In addition, if the raw material contains a certain amount of feldspar minerals with a specific gravity similar to that of quartz, it can use the flotation process to remove these impurities.

At the same time, if the quartz minerals and gangue minerals do not reach a certain degree of monomer dissociation, it is necessary to increase the fineness of grinding.

Equipment Needed:

Flotation machine

Specific Flow of Flotation Operation

It can use three-stage flotation process to remove mica minerals and feldspar minerals in the quartz sand.

The first-stage flotation is to flotate iron-containing mud from the slurry by using the corresponding reagent system in a neutral or weak acid environment.

The second-stage flotation is to flotate mica minerals and the conjoined body of mica and quartz from the slurry in a neutral or weak acid environment.

The third-stage flotation is to flotate feldspar minerals and the conjoined body of feldspar and quartz from the slurry under a neutral or weak acid environment.

(5) Pickling Method

If the the product sand after the removal and selection operation is reddish, and the iron and titanium content is too high to meet the product quality requirements, it can use pickling method.

Firstly, wash to remove powder and impurities, then do pickling soaking and washing, and finally dry the product.

03To Wrap Up

BackThe above is the quartz sand impurities removal process and required equipment. The impurities removal is carried out when the impurities and quartz minerals reach the state of monomer dissociation, and almost all impurity minerals in the raw materials can be removed, thus greatly improving the purity of the quartz sand. In the end, you can obtain the corresponding quartz sand concentrate products.

If you have any questions about the quartz sand impurities removal process or need the equipment mentioned, please leave a message to communicate with us or consult our online customer service.

+86 13810565920

+86 13810565920 xlyin@xinhaimining.net

xlyin@xinhaimining.net

Message

Message Chat Now

Chat Now