6 Common Magnetic Separation Equipment for Magnetite Separation

Shirley

Shirley

Nov 16, 2021

Nov 16, 2021

3590

3590

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Magnetite is a common iron oxide mineral with high iron content and is an important material for the production of iron and steel. Magnetite has strong magnetism and is usually separated by magnetic separation process. Common magnetic separators include magnetic drums, cylindrical magnetic separators, magnetic separation columns, magnetic screens, magnetic desliming tanks, demagnetizers, etc. This article will take you to learn more about these 6 types of magnetic separation equipment.

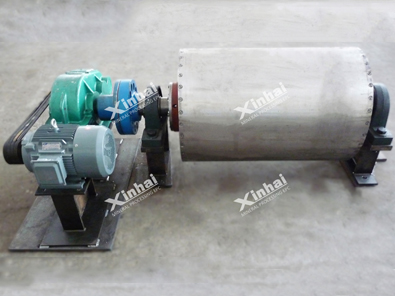

01 Magnetic Drum

BackMagnetic drum, also known as the magnetic pulley, is mainly used for the separation of magnetite rich block ore and the tailing of coarse particles. The magnetic system structure mainly includes axial magnetic level arrangement and radial magnetic pole arrangement. The magnetic system structure can be determined according to the volume magnetic susceptibility and particle size of the separated materials. The maximum particle size is 100mm, and the minimum particle size is 10mm. The single processing capacity depends on the feeding particle size, and the maximum processing capacity is 250t/(h•m).

02 Cylindrical Magnetic Separators

BackCylindrical magnetic separator is the main equipment for magnetite beneficiation, mainly including dry and wet type.

(1) Dry Permanent Magnet Cylindrical Magnetic Separator

Dry permanent magnet cylindrical magnetic separator is the magnetic separation equipment which adopts multi-pole radial magnetic pole arrangement and open magnetic system structure. It is mainly used for dry dumping of fine magnetite ore or dry separation in areas lacking water. The maximum particle size is 30mm, and the minimum particle size is -200 mesh (-0.074mm), and the content is less than 40%. The processing capacity of the single machine also depends on the feeding particle size, with a maximum processing capacity of 20 t/(h•m).

(2) Wet Permanent Magnet Cylindrical Magnetic Separator

Wet permanent magnet cylindrical magnetic separator is also a magnetic separation equipment with multi-pole head radial arrangement and open magnetic system structure. For roughing, concentration or scavenging operations, the distribution of the surface magnetic field and the peak magnetic field intensity change accordingly, and different types of sorting trough types (downstream, counter-current and semi-counter-current) can be selected. The maximum particle size is 10mm, the minimum particle size is -200 mesh (-0.074mm) content is less than or equal to 90%. The single processing capacity depends on the feed particle size and separating tank type, the maximum processing capacity is 60 t/(h•m).

03 Magnetic Separation Column

BackMagnetic separation column is a kind of magnetic - heavy separation equipment which combines electromagnetic weak magnetic field magnetic system with separation column. Using multi-stage alternating solenoid magnetic field, the fine-grained ferromagnetic mineral particles alternately generate magnetic polymerization and loosening, while the rising water flow effectively removes monomer gangue or lean conjoined particles with a small specific gravity from the feedstock. Magnetic separation column is mainly used for fine-particle magnetite beneficiation operations to improve concentrate grade and beneficiation separation efficiency. At present, due to the limitation of the equipment structure, the processing capacity is relatively low.

04 Magnetic Screen

BackMagnetic screen is also a kind of magnetic-heavy combined separating equipment. After the effective agglomeration of magnetite in weak magnetic field, the magnetic material is discharged from the screen, gangue and lean intergrowth body are discharged from the screen by special sieve installed in magnetic field, so as to realize effective separation. Magnetic screen is mainly used for magnetite beneficiation operations to improve concentrate grade and beneficiation separation efficiency. It also has a small single-machine processing capability due to structural limitations.

05 Magnetic Desliming Tank

BackMagnetic desliming tank is the separation equipment for magnetic- gravity that is commonly used in magnetite processing plants. It is mainly used for the removal of fine gangue and slime, and sometimes also for the desliming of magnetite, so it is also called magnetic dewatering tank. The magnetic system structure of the magnetic desliming tank mainly includes the lower permanent magnet system, the upper permanent magnet system and the upper electromagnetic magnet system. The magnetic field distribution of the upper permanent magnet and electromagnetic magnet system is basically the same, and its water supply mode is different from that of the lower magnetic desliming tank.

06 Demagnetizer

BackThe demagnetizer uses alternating magnetic field to make magnetite particles lose remanence so as to improve the separation accuracy of the next separation operation. In general, the demagnetization operation is carried out before the coarse concentrate of magnetite first stage magnetic separation enters the second stage grinding or the second stage cleaning. In general, the demagnetization operation is carried out before the coarse concentrate of magnetite first stage magnetic separation enters the second stage grinding or the second stage concentration.

07To Wrap Up

BackThe above are the six types of magnetic separation equipment commonly used in the magnetite magnetic separation process. In addition to magnetite, they are also widely used in the separation of ilmenite, chromite, manganese, quartz, feldspar, kaolin and other minerals. Due to the complexity of natural mineral resources, magnetic separation equipment can only exert positive effects if it meets the ore characteristics. It is recommended that the beneficiation plants owners first carry out beneficiation test, and determine the appropriate beneficiation process and equipment according to the test results.

+86 18234403483

+86 18234403483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now