Mobile Crushing Station Transportation Process and Layout Requirements

Shirley

Shirley

Jun 07, 2021

Jun 07, 2021

2587

2587

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

The mobile crushing station is the multifunctional equipment that integrates the functions of feeding, crushing and screening. It can be moved and operated at any time according to the needs of the site. The mobile crushing station in open pit stope is mainly used for continuous transportation proce and semi-continuous transportation process. This article will take you to understand the two kinds of transportation process and the layout requirements of mobile crushing station.

01 Mobile Crushing Station Transportation Process

Back#1 Continuous Transportation Process

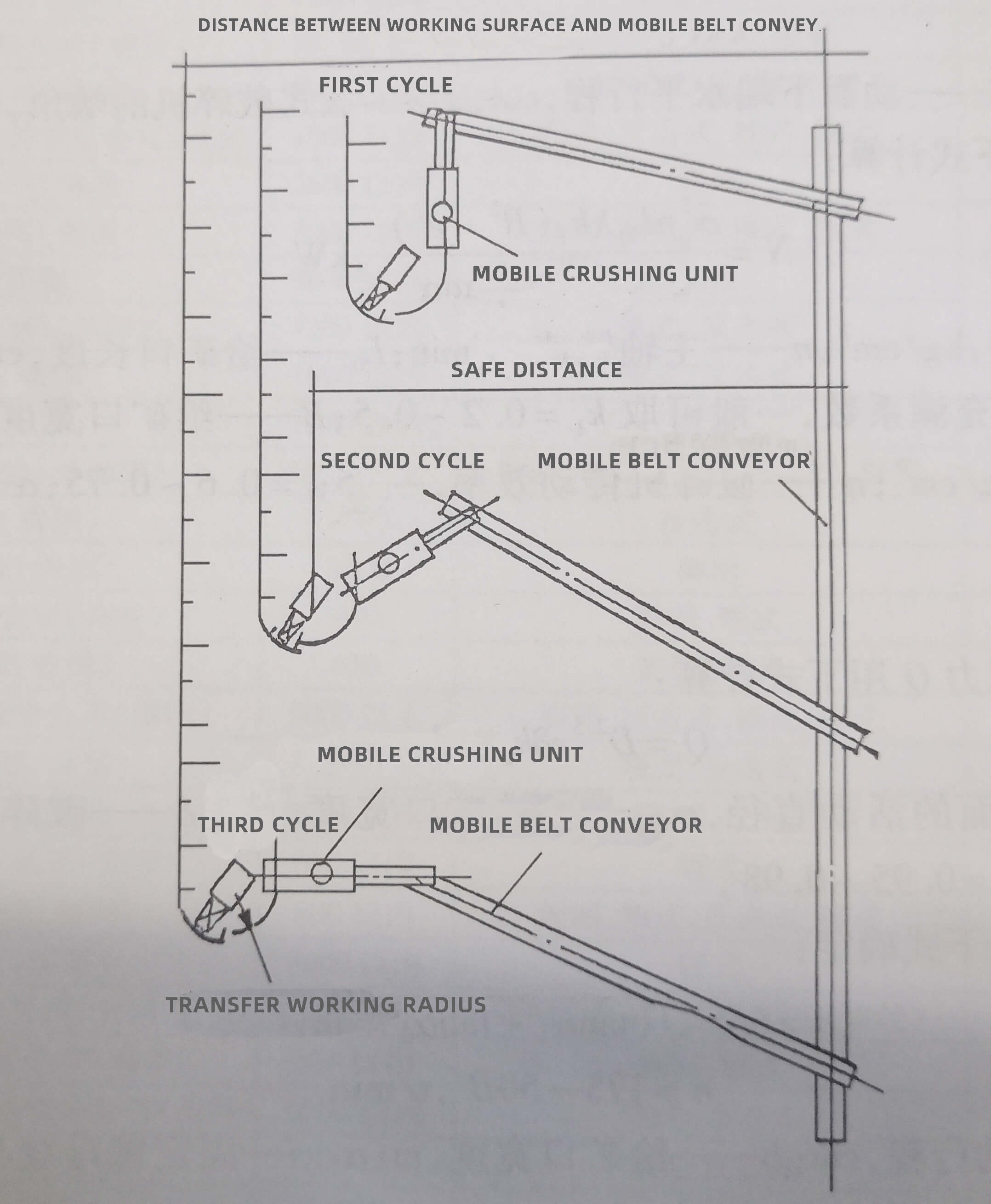

The continuous transportation process system is composed of loader-mobile crusher-mobile belt conveyor-fixed belt conveyor. Loading equipment on the stripping face, such as excavator, front loader, etc., will carry ore to the mobile crusher. The crushed ore are transferred to the mobile belt machine to complete the internal transportation of the stope working face. The ore is then transferred to the conveyor fixed on the slope and transported to the ore warehouse. The excavator-mobile crusher-transportable conveyor belt conveyor-mobile belt conveyor-fixed belt conveyor can also constitute a continuous transportation process. The layout of this process is shown in the figure below.

(Continuous Transportation Process Layout)

#2 Semi-continuous Transportation Process

Semi-continuous transportation process is also called discontinuous-continuous transportation process. Its system is composed of excavator - automobile - semi - fixed crusher - fixed belt machine.

The ores are loaded onto the automobile by excavators. The automobile complete the horizontal transportation inside the open pit and transports the ore to the semi-stationary crusher on the slope. After crushing, the ore is transferred to the slope belt conveyor. This is actually an automobile -belt conveyor combined transportation program. In this program, the transportation distance of the car is short, which improves the transportation efficiency of the car and takes advantage of the belt conveyor. Therefore, the automobile-belt conveyor combined transportation program is currently one of the most commonly used transportation programs in various countries.

In the intermittent-continuous transportation process, the semi-stationary crusher is the key to transfer. It can be moved down regularly with the horizontal extension of the open pit. In the design, the movement of the crusher should be minimized. Because the crusher transfer station used in this scheme is basically fixed, there are more technical problems when moving.

02 Mobile Crushing Station Layout Requirements

BackThe following seven requirements should be followed when the mobile crushing station is arranged.

(1) The control room should be located above one side of the coarse ore bin. There should be a good perspective and be able to see the unloading port, warehouse and gravel working conditions, in order to command the vehicle in and out of the unloading operation, control the crusher operation.

(2) For unqualified large blocks, crushers can be installed on the top of the coarse crushing ore bin.

(3) The metallurgical open-pit mine adopts a continuous work system with three shifts daily. In order to shorten the downtime, the integral parts are often replaced and overhauled. Therefore, it is required to leave enough replacement parts (such as moving cones, beams, upper and middle frame bodies, machine bases, eccentric sleeves, bevel gears, liners, etc.) on one side of the coarse crushing silo for stacking and maintenance sites.

(4) The crusher is controlled by the control room of the coarse crushing ore bin, and a control room that can be operated on site should be set in the crusher. The maintenance platform around the crusher should be detachable. In order to prevent the dust from escaping from the inspection channel of the hydraulic device at the bottom of the cone during the operation of the crusher, a detachable airtight partition with good sealing performance must be provided. When the terrain conditions permit, the crusher room should be provided with a door leading to the outside to enhance ventilation, lighting and facilitate the transportation of components during installation and maintenance.

(5) In order to adjust the discharging of the crusher and the balance of the belt conveyor operation, a buffer storage bin should be set up. High and low level gauges should be set in the buffer silo. The former is often installed in the mercury switch steel pipe, hanging in the steel protective cover under the crusher, in order to prevent the drainage port is filled with ores blocked. The latter is to ensure that the ore cushion layer is provided to the ore feeder. The inner wall of the buffer silo is lined with a protective layer of manganese steel or steel rail to reduce wear.

(6) The feeder at the bottom of the buffer silo must match the conveyor. When using a plate feeder, the clear distance from the center of the tail wheel to the outside of the chute should accommodate more than 3 trough plates. In order to facilitate maintenance, a lifting beam is also required above the tail wheel. The operation room beside the observation window on the side of the front guard of the plate feeder should be sealed and removable.

(7) Dust will be produced when the materials on the coarse crushing ore bin are unloaded, so high pressure water nozzles should be set at each unloading point for spray suppression, so that the materials can fall into the ore bin through the water backstage. The position of nozzles and the laying of water pipes should be prevented from being damaged by unloaded materials. The dust produced when crushing materials and loading on the conveyor is commonly used for extraction ventilation and wet dust collector to keep the buffer ore bin in the state of negative pressure, so as to obtain better dust collection effect.

03To Wrap Up

BackThis article introduces the two transportation processes used in the mobile crushing station and their layout requirements. As a mobile crushing equipment, its good mobility can greatly increase output and reduce operating costs. When purchasing and deploying mobile crushing stations, you can consult with professional equipment manufacturers to avoid detours.

+86 182 3440 3483

+86 182 3440 3483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now