Copper Extraction from Ores: A Comprehensive Guide

Laura

Laura

May 20, 2025

May 20, 2025

2770

2770

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

copper mine pic

Copper, a cornerstone of modern industry, is essential for electrical wiring, renewable energy systems, and construction. Extracting copper from ores involves a multi-stage process that combines physical and chemical methods to maximize yield and efficiency. This guide explores the beneficiation and extraction processes, offering insights into optimizing copper recovery while addressing environmental considerations.

01 Types of Copper Ores

BackCopper occurs primarily as sulfide ores (e.g., chalcopyrite, bornite) and oxide ores (e.g., cuprite, malachite). Sulfide ores dominate global production, while oxide ores often require specialized extraction techniques due to their lower copper content.

copper ore pic

02 The Copper Beneficiation Process

BackBeneficiation prepares raw ore for extraction by concentrating copper minerals. Key stages include:

a. Crushing and Grinding

Primary Crushing: Large ore chunks are reduced to smaller fragments using jaw or gyratory crushers.

Grinding: Ball mills or rod mills further pulverize the material into a fine powder, liberating copper minerals from gangue (waste rock).

b. Froth Flotation

This critical step separates copper minerals from waste:

Conditioning: Chemicals (collectors, frothers) are added to slurry to make copper particles hydrophobic.

Flotation Cells: Air bubbles carry hydrophobic copper particles to the surface, forming a froth skimmed off as copper concentrate (20–30% Cu).

Tailings Management: Waste slurry (tailings) is dewatered and stored responsibly to minimize environmental impact.

c. Concentration and Dewatering

Copper concentrate undergoes thickening and filtration to reduce moisture content, preparing it for smelting.

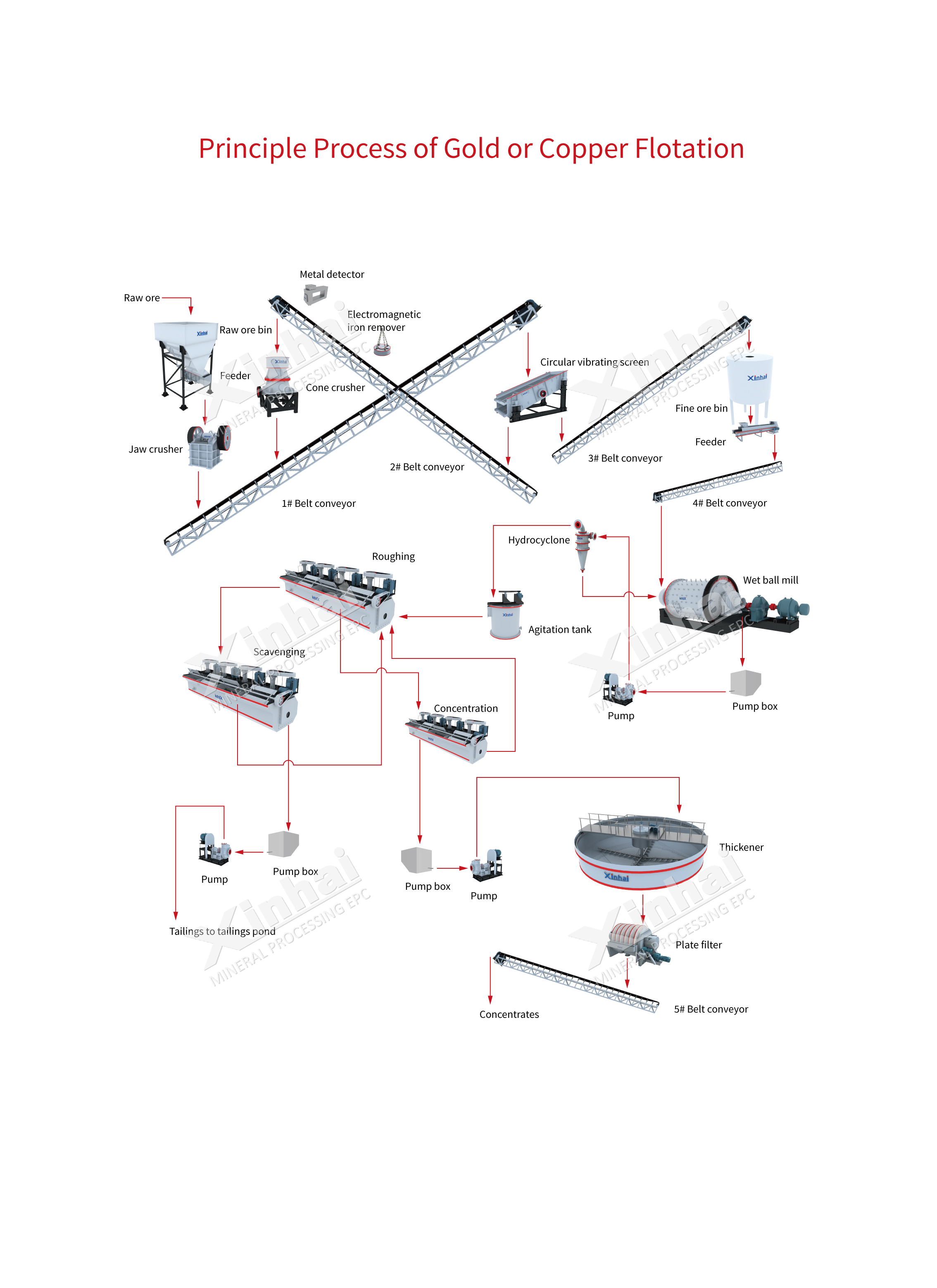

Copper or gold ore flotation process flowchart

03 Copper Extraction Methods

Backa. rometallurgical (Smelting)

Roasting: Concentrate is heated to remove sulfur, converting sulfides to oxides.

Smelting: Oxides are melted in a furnace (e.g., flash smelter) to produce matte (40–70% Cu).

Converting: Matte is refined in a converter to remove iron and sulfur, yielding blister copper (98–99% Cu).

Electrorefining: Blister copper is electrolytically purified to 99.99% pure copper cathodes.

b. Hydrometallurgical (Leaching)

Used for oxide or low-grade ores:

Heap Leaching: Ore is piled and irrigated with acid (e.g., sulfuric acid), dissolving copper into a solution.

Solvent Extraction (SX): Copper ions are transferred to an organic solvent.

Electrowinning (EW): Electricity plates pure copper onto cathodes from the solution.

copper mining

04 Environmental and Efficiency Considerations

BackWater Recycling: Closed-loop systems reduce freshwater consumption.

Tailings Management: Dry-stack tailings and reprocessing minimize waste.

Emissions Control: Smelters use scrubbers to capture sulfur dioxide (SO₂), converting it to sulfuric acid.

05 Innovations in Copper Extraction

BackBioleaching: Bacteria oxidize sulfide ores, enabling eco-friendly low-grade ore processing.

Sensor-Based Sorting: AI and sensors improve ore pre-concentration, reducing energy use.

06Conclusion

BackFrom beneficiation to refining, copper extraction demands precision and innovation to meet global demand sustainably. By integrating advanced flotation techniques, energy-efficient smelting, and responsible tailings management, the industry can balance productivity with environmental stewardship.

Feel free to contact us and learn more about copper processing solutions!

+86 182 3440 3483

+86 182 3440 3483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now