How Do You Remove Impurities from Bauxite? Guide to the Beneficiation

Laura

Laura

May 02, 2025

May 02, 2025

1458

1458

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Bauxite ore

Bauxite, the primary ore for aluminum, is naturally packed with impurities like silica, iron oxides, and clay. These contaminants must be removed to unlock the aluminum-rich alumina hidden inside. This purification process, called beneficiation, combines physical and chemical methods to transform raw bauxite into a usable product. In this guide, we'll break down how it works.

01 Why Remove Impurities from Bauxite?

BackHigher Aluminum Yield: Impurities reduce the amount of alumina extracted, raising production costs.

Protect Equipment: Silica and iron can damage smelting machinery.

Environmental Safety: Proper removal minimizes toxic waste like red mud.

Bauxite ore

02 The Bauxite Beneficiation Process: Step-by-Step

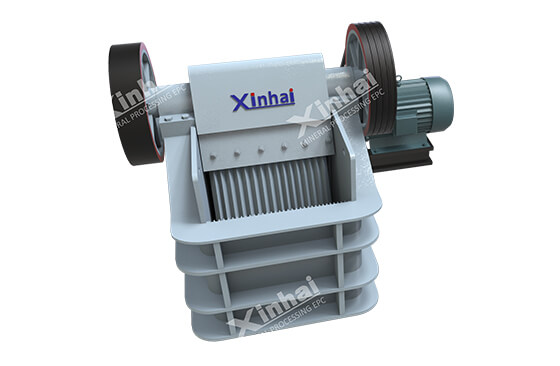

Back1. Mining and Crushing

Bauxite is typically surface-mined from open pits in countries like Australia, Guinea, and Brazil.

Crushing: Giant jaw crushers or gyratory crushers break the ore into 5–10 cm chunks.

Goal: Increase surface area for efficient impurity removal in later stages.

Jaw crusher

2. Washing and Scrubbing

Clay and loose silica are the first impurities to go.

Log Washers: Rotating drums with paddles scrub bauxite, dislodging sticky clay.

High-Pressure Water Jets: Blast away silica and fine particles.

Dry Scrubbing (Innovation): In water-scarce regions, air and vibration replace water to clean ore.

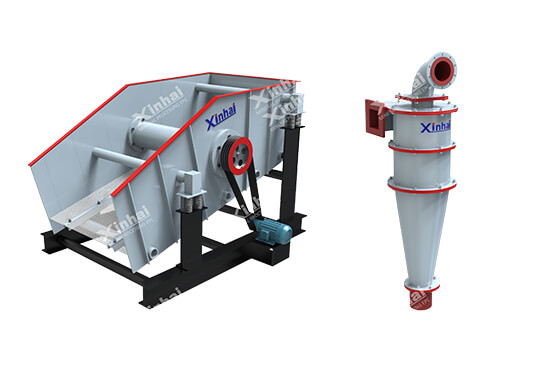

3. Screening and Classification

Vibrating Screens: Separate washed bauxite into coarse and fine fractions.

Hydrocyclones: Spin mixtures to segregate particles by density, removing lighter silica.

Why It Works: Silica particles are often smaller and lighter than bauxite.

Vibrating screens and hydrocyclone

4. Magnetic Separation

Drum Magnets: Extract iron-rich minerals like hematite (Fe₂O₃) from the bauxite stream.

High-Intensity Magnetic Separators (HIMS): Remove stubborn iron impurities with powerful magnetic fields.

Example: Mines in Guinea use HIMS to reduce iron content from 15% to 5%.

Magnetic separators

5. Froth Flotation (For Stubborn Silica)

Flotation Cells: Air bubbles injected into a chemical slurry lift silica to the surface as froth.

Chemicals: Fatty acids or other collectors make silica “sticky” to bubbles.

Efficiency: Removes up to 50% of residual silica.

Flotation cells

6. The Bayer Process: Final Chemical Purification

After physical beneficiation, bauxite undergoes the Bayer process to extract pure alumina (Al₂O₃):

Digestion: Bauxite is mixed with hot sodium hydroxide (NaOH), dissolving alumina into a liquid.

Clarification: Impurities like iron and silica sink as “red mud” and are filtered out.

Calcination: The purified alumina solution is heated to remove water, leaving a white powder.

03 Key Machines Used in Beneficiation

BackJaw Crushers: Break down raw bauxite into manageable chunks.

Hydrocyclones: Separate silica using centrifugal force.

Magnetic Separators: Remove iron oxides.

Filter Presses: Dewater waste sludge into dry “cakes” for safe disposal.

Jaw crushers-Hydrocyclones-Magnetic separators-Filter presses

04 Environmental Challenges and Solutions

BackRed Mud Management: Stored in lined ponds to prevent groundwater contamination. Companies like Alcoa repurpose it into cement.

Water Recycling: Modern plants reuse 90% of water from washing.

Energy Efficiency: Solar-powered crushing units in India cut carbon emissions.

05 Innovations in Bauxite Purification

BackLaser Sorting: Sensors detect impurities and blast them with air jets, reducing waste.

Bioleaching: Bacteria dissolve silica naturally, slashing chemical use.

AI Optimization: Smart systems adjust screen sizes and chemical doses in real time.

Bauxite mine

06 FAQs

BackQ: Why is silica a problem in bauxite?

A: Silica reacts with chemicals during refining, increasing costs and creating more red mud.

Q: Can all bauxite be purified?

A: Low-grade bauxite (<40% alumina) is often too expensive to process due to high impurity levels.

Q: How much waste is produced?

A: For every ton of alumina, 1–2 tons of red mud are generated.

07Conclusion

BackRemoving impurities from bauxite is a blend of brute-force engineering and precision chemistry. From scrubbing away clay to zapping silica with lasers, each step ensures the ore meets the high standards of aluminum production. While challenges like red mud and energy use persist, innovations in dry processing and bioleaching promise a cleaner, greener future. For industries and eco-conscious consumers alike, understanding this process highlights the hidden effort behind every piece of aluminum we use.

Feel free to contact us and learn more about bauxite processing solutions!

+86 182 3440 3483

+86 182 3440 3483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now