High-Purity Quartz Sand Beneficiation Methods and Line Inventory!

shirley

shirley

Feb 28, 2023

Feb 28, 2023

1148

1148

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

The chemical composition of quartz sand is silicon dioxide (SiO2), while high-purity quartz sand means that the SiO2 content is higher than 99.9%. As one of the important industrial raw materials, quartz can be widely used in glass, building materials, plastics, electronic materials and other industries. Among them, the fields of electronic technology, aerospace, optical fiber communication and military industry have higher requirements on the purity of quartz sand. This article will take stock of the beneficiation method and processing line of high-purity quartz sand.

01High-purity quartz sand beneficiation method

BackIn industrial production, ordinary quartz sand is usually pretreated first, and then purified into high-purity quartz sand. The purification methods mainly include physical purification, chemical purification and biological purification.

1. Physical purification of high-purity quartz sand

The common physical purification methods of high-purity quartz sand can include water washing-classification desliming, scrubbing, gravity separation, magnetic separation and flotation, etc. Through one or more combination forms, the impurity minerals in the quartz sand are removed to meet the purification requirements.

(1) Water washing - graded desliming/scrubbing

In the beneficiation process of quartz sand, the particle size less than 0.1mm is usually called slime. As its particle size becomes finer, the grade of silica will be lower and lower, and the impurity ore will be relatively more. Therefore, impurity minerals can be removed and the grade of quartz concentrate can be improved by water washing-grading desliming or scrubbing.

(2) Gravity separation

The main use of the relative density, particle size, and shape differences between the particles of the minerals is to cause them to produce different speeds of movement and distribute in different directions under the action of water and centrifugal force to separate the minerals.

(3) Magnetic separation

Mainly use the magnetic separation difference between quartz and impurity ores to remove hematite, limonite, biotite and other magnetic minerals in the minerals to the greatest extent through magnetic separation equipment.

(4) Flotation

Use reagents and flotation equipment to change the difference in surface properties between minerals. Select high-purity quartz sand from other places under acidic conditions to remove fine-grained hematite, biotite, garnet and aluminum minerals in the minerals.

2. Chemical purification of high purity quartz sand

The chemical purification methods of high-purity quartz sand mainly include acid leaching and alkali leaching, and the purification effect of high-purity quartz sand is better.

(1) Pickling

Commonly used acids are mainly sulfuric acid, hydrochloric acid, nitric acid, hydrofluoric acid and so on. When the acid is relatively dilute, it has a better effect on removing impurities such as iron, aluminum, and magnesium. When the acid is relatively concentrated, it has a good effect on removing impurities such as titanium and chromium.

(2) Alkaline leaching

Alkaline solutions such as sodium hydroxide or sodium carbonate are commonly used to dissolve aluminum-containing silicate impurity minerals to achieve the purpose of purifying quartz sand.

3. High-purity quartz sand biological purification

The biological purification method of high-purity quartz sand mainly adopts microbial leaching purification. Utilizing the physiological functions of microorganisms and their metabolites, through oxidation, dissolution and decomposition, the impurities on the surface of the quartz sand are separated from the quartz matrix to achieve the purification of the quartz sand.

02High-purity quartz sand processing line

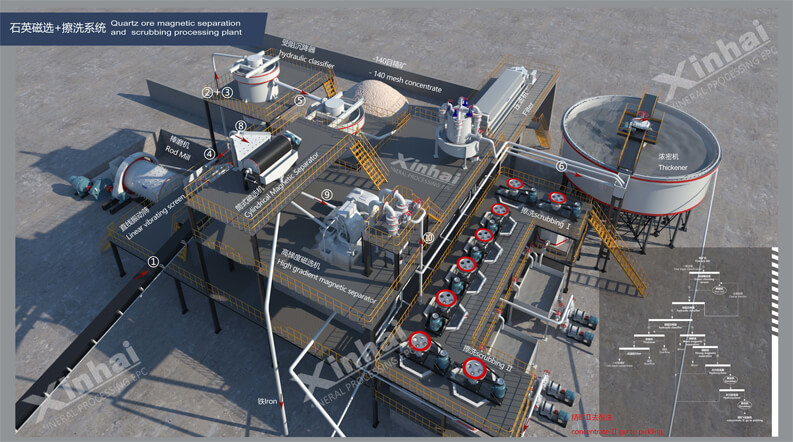

BackIn the beneficiation process, the production line process of high-purity quartz sand mainly includes: crushing-grinding-classification-magnetic separation-flotation-acid leaching-or washing and other links.

1. Quartz sand crushing

Generally, a two-stage crushing process is adopted. First, the jaw crusher is used for coarse crushing. The crushed product is conveyed by belt to vibrating screen for screening. Unqualified materials are sent to the cone crusher for fine crushing. Qualified materials are sent to the fine ore bin.

2. Grinding and grading

The ore grinding link is mainly to grind the raw ore to a certain particle size to realize the dissociation of quartz sand and gangue minerals. Classification is used in conjunction with grinding equipment to obtain quartz sand materials with qualified particle sizes.

3. Magnetic separation

Wet magnetic separators with magnetic field strengths of 3000Oe and 10000Oe were used for primary separation to remove garnet, hematite, limonite, ilmenite and their associated particles in the quartz sand.

4. Flotation

It is used to remove mica and Fe2O3 in quartz, using H2SO4 as regulator, pH=2.5~3, sodium petroleum sulfonate as collector, pine oil as foaming agent to realize flotation operation.

5. Pickling

After magnetic separation and flotation, there are still impurities in the form of spots or inclusions in the quartz. To remove this part of impurities, acid leaching treatment is required, and different acids are mixed to remove different impurities.

6. Washing

After acid leaching, the surface of the quartz sand has adhering and dissolved soluble impurity residues, which need to be removed by washing. Wash the minerals after acid leaching to make the impurities and residual liquid on the surface of the quartz diffuse to the liquid phase, and then complete the washing.

03To Wrap Up

BackThe above mainly introduces the beneficiation method of high-purity quartz sand and the process of the quartz sand production line. In the actual beneficiation plant, according to the ore properties and impurity types of quartz sand, the beneficiation method and the process of the beneficiation production line are different. If you want to obtain High-purity quartz sand needs to be determined according to its ore properties. Therefore, it suggests that through mineral processing test analysis, design and customize a suitable process plan and suitable high-purity quartz sand production line process, in order to obtain quartz sand with a high return on investment .

+86 182 3440 3483

+86 182 3440 3483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now