How Much for a Complete Kaolin Processing Plant?

Laura

Laura

Oct 24, 2023

Oct 24, 2023

1454

1454

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

( Myanmar 500tpd mineral dressing plant project site )

01Introduction

BackThe kaolin industry is a significant player in various sectors, including ceramics, paper, paint, and coatings. With the increasing demand for kaolin products, many entrepreneurs and businesses are considering investing in a complete kaolin processing plant. However, understanding the cost involved in setting up such a plant is crucial for making informed decisions. In this blog post, we will explore the factors that influence the pricing of a complete kaolin processing plant and provide insights into the financial considerations involved.

02Market Analysis and Demand

BackBefore delving into the cost aspect, it is essential to conduct a thorough market analysis. Understanding the market demand for kaolin products is crucial in determining the feasibility of investing in a complete processing plant. Analyzing the market trends, identifying potential customers, and assessing the demand in various industries and regions will help estimate the investment required.

03Plant Size and Capacity

BackThe size and capacity of the processing plant directly impact the cost. A larger plant with a higher production capacity will require more substantial capital investment. Factors such as land cost, infrastructure development, equipment procurement, and construction expenses contribute to the total cost. Conducting a feasibility study to determine the optimal plant size based on market demand and long-term growth projections is crucial.

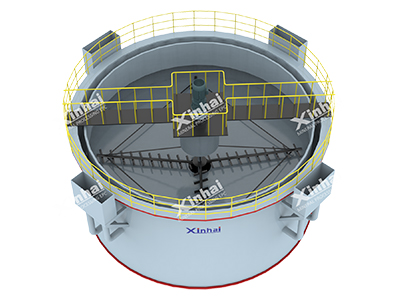

04Equipment and Technology

BackInvesting in modern and efficient equipment is vital for a successful kaolin processing plant. The selection of machinery depends on the desired output quality, processing techniques, and cost-efficiency. Advanced equipment often comes with a higher price tag, but it can enhance productivity, reduce energy consumption, and improve product consistency. Evaluating equipment options, considering long-term operational costs, and balancing quality with affordability are crucial aspects of cost analysis.

05Raw Material Acquisition and Transportation

BackA steady supply of high-quality raw materials is essential for kaolin processing plants. The cost and availability of acquiring kaolin deposits can vary depending on the location. Transportation logistics also play a significant role in determining costs. Proximity to raw material sources and transportation infrastructure can significantly impact the investment required. Analyzing the availability and cost of raw materials is essential for accurate cost estimation.

06Labor and Workforce

BackThe workforce required for a complete kaolin processing plant encompasses various roles, including skilled technicians, engineers, operators, and administrative staff. Labor costs can vary depending on geographical location, prevailing wages, and industry expertise. It is crucial to evaluate labor requirements, training needs, and associated expenses when estimating the investment for the plant. Additionally, considering employee benefits, safety measures, and potential labor market fluctuations is essential for long-term financial planning.

07Regulatory Compliance and Environmental Considerations

BackComplying with regulatory requirements and environmental standards is crucial for the sustainable operation of a kaolin processing plant. Obtaining permits, conducting environmental impact assessments, and implementing necessary pollution control measures can add to the overall investment. It is important to factor in the costs associated with compliance and environmental considerations to avoid unexpected expenses and ensure the plant's long-term viability.

08Operational Costs and Maintenance

BackIn addition to the initial investment, understanding the ongoing operational costs and maintenance expenses is vital. These costs include utilities, raw material replenishment, labor, equipment maintenance, and repairs. Careful budgeting and financial forecasting are essential to ensure the plant's profitability and sustainability in the long run. Regular maintenance and equipment upgrades are necessary to optimize productivity and avoid costly downtime.

09Financial Analysis and Return on Investment

BackBefore committing to a complete kaolin processing plant, conducting a thorough financial analysis is crucial. This analysis should include estimating the payback period, calculating the return on investment (ROI), and assessing the plant's profitability. Factors such as market demand, pricing strategies, operational efficiency, and production costs should be considered. Working closely with financial advisors or consultants can help develop accurate financial projections and make informed investment decisions.

10Conclusion

BackInvesting in a complete kaolin processing plant requires a comprehensive understanding of the financial implications involved. Market analysis, plant size, equipment selection, raw material acquisition, labor costs, regulatory compliance, and ongoing operational expenses all contribute to the overall investment. By carefully evaluating these factors and conducting a thorough financial analysis, entrepreneurs and businesses can make informed decisions and maximize the chances of success in the kaolin processing industry. It is crucial to consider both upfront costs and long-term profitability to ensure the plant's sustainability and achieve the desired return on investment.

Tags: Ready to scale up your kaolin production? Contact us now to explore how a complete processing plant can meet your capacity and quality requirements!

+86 182 3440 3483

+86 182 3440 3483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now