Unveiling the Innovations in Rare Earth Processing Technology

Shirley

Shirley

Jan 10, 2024

Jan 10, 2024

1397

1397

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Rare earth elements (REEs) play a vital role in various industries, from electronics and renewable energy to defense and healthcare. The processing of rare earth minerals requires advanced technologies to extract and refine these valuable elements efficiently. This comprehensive guide explores the latest innovations in rare earth processing technology, highlighting sustainable practices and the pursuit of responsible resource utilization.

01The Significance of Rare Earth Elements

BackRare earth elements are a group of seventeen metallic elements with unique properties that make them essential in the manufacturing of high-tech products. From neodymium magnets in electric vehicles to phosphors in LED displays, rare earth elements enable technological advancements that shape our modern world.

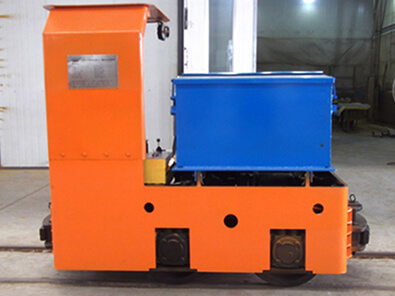

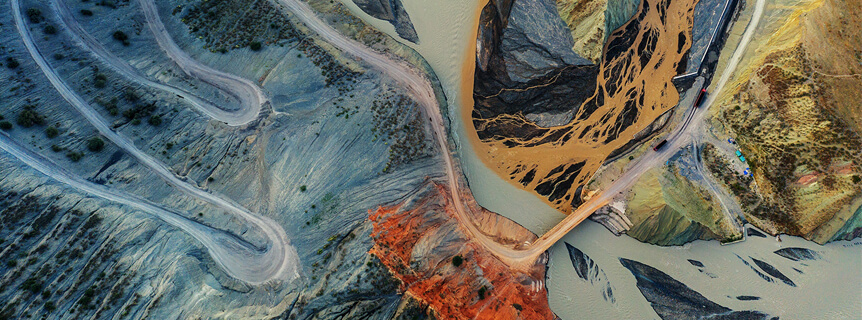

02Rare Earth Mining and Ore Extraction

BackRare earth minerals are typically found in complex geological formations, making their extraction a challenging process. Innovative mining methods, such as in-situ leaching and selective mining, minimize environmental impact and reduce waste generation. Advanced exploration techniques, including remote sensing and geochemical analysis, aid in the identification and evaluation of rare earth deposits.

03Beneficiation and Concentration

BackTo optimize the extraction of rare earth elements, ore beneficiation techniques are employed. Physical separation methods, such as gravity separation, magnetic separation, and flotation, are utilized to concentrate the rare earth minerals and remove impurities. State-of-the-art technologies, such as sensor-based sorting and automated mineralogy, enhance the efficiency of ore beneficiation processes.

04Hydrometallurgical Processing

BackHydrometallurgical processes are commonly employed for rare earth extraction from concentrated ores. Acid leaching and solvent extraction techniques are used to dissolve and separate the rare earth elements from the ore matrix. Advanced solvent extraction systems and novel extractants improve the selectivity and efficiency of rare earth recovery, minimizing chemical consumption and waste generation.

05Pyrometallurgical Processing

BackIn certain cases, pyrometallurgical processes are utilized to extract rare earth elements. High-temperature techniques, such as calcination, roasting, and smelting, are employed to convert rare earth minerals into more manageable forms. Innovative pyrometallurgical technologies, including microwave heating and plasma smelting, offer energy-efficient and environmentally friendly alternatives to traditional methods.

06Recycling and Circular Economy

BackWith growing concerns over resource scarcity and environmental impact, recycling of rare earth elements from electronic waste and end-of-life products has gained significance. Advanced recycling technologies, such as solvent extraction and ion exchange, enable the recovery of rare earth elements from complex waste streams. The promotion of a circular economy approach ensures the sustainable utilization of rare earth resources.

07Environmental Stewardship and Sustainability

BackThe rare earth processing industry is committed to minimizing its environmental footprint. Efforts are focused on efficient waste management, water conservation, and the reduction of greenhouse gas emissions. Adoption of cleaner technologies, renewable energy sources, and eco-friendly reagents contribute to the industry's sustainability goals.

08Future Trends and Technological Advancements

BackThe quest for sustainable rare earth processing continues to drive innovation. Emerging technologies, such as bioleaching, electrochemical processing, and ion adsorption recovery, show promising potential in improving efficiency and reducing environmental impact. The integration of digitalization, automation, and artificial intelligence enhances process control and optimization, making rare earth processing safer and more efficient.

09To Wrap Up

BackRare earth processing technology is evolving rapidly to meet the demand for these critical elements sustainably and responsibly. By embracing innovative extraction, beneficiation, and refining techniques, the industry strives to minimize environmental impacts, reduce waste generation, and promote resource efficiency. Our collective commitment to advancing rare earth processing technology ensures a brighter future for industries that rely on these indispensable elements. Let us embark on this journey of innovation and sustainability, unlocking the potential of rare earth elements for a better tomorrow.

+86 183 3575 8886

+86 183 3575 8886 pinklaurabao@gmail.com

pinklaurabao@gmail.com

Message

Message Chat Now

Chat Now