3 Types of Jig Machine You Need to Know

shirley

shirley

Nov 06, 2020

Nov 06, 2020

5693

5693

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

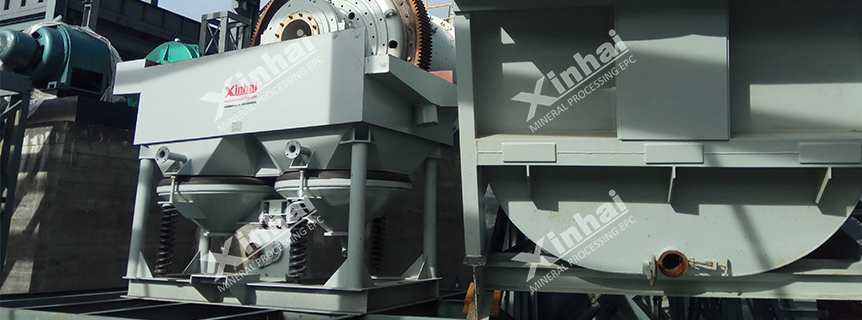

(Jig machine in mineral processing plant)

In the post, we are talking about the types and application of jig machine. We are going to introduce 3 kinds of jigger with its application in daily life.

The jig machine is a gravity separation equipment that separates light and heavy minerals by different gravity. According to their structure, jigs can be divided into plunger jigs, diaphragm jigs, air pulsating jigs, moving jigs, etc. However, plunger jig is basically no longer to use.

01 Diaphragm Jig

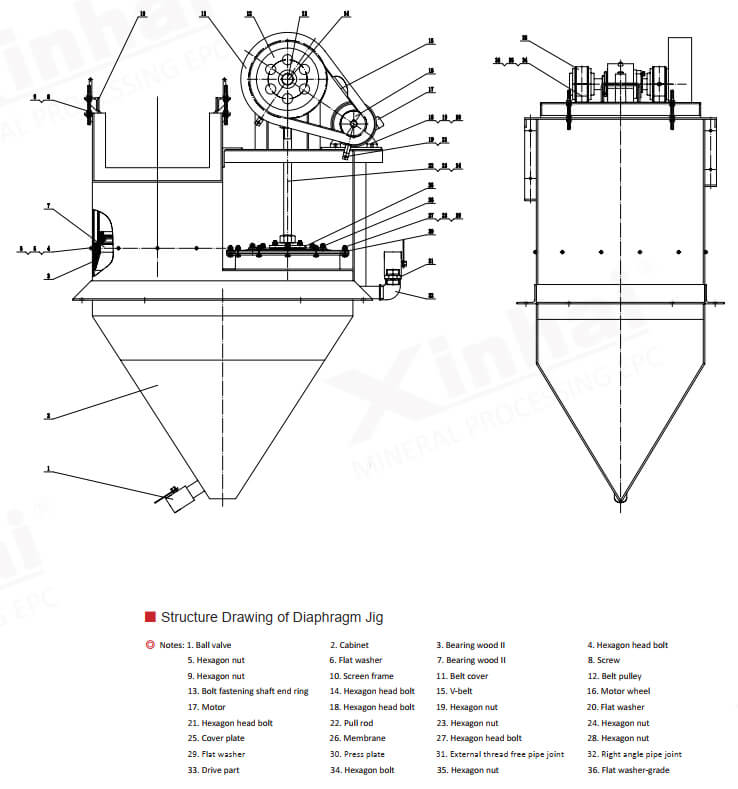

BackDiaphragm jig is a type of jigging machine that is widely used in gravity separation plants, whose working principle is to drive the diaphragm by eccentric connecting rod, cam lever or hydraulic device causing reciprocating motion. Based on the diaphragm installation position, diaphragm jigs can be divided into top-moving (side-moving) diaphragm jigs, down-moving conical diaphragm jigs, lateral diaphragm jigs, and so on.

(1) Top-moving (side-moving) diaphragm jig

Top-moving diaphragm jigs are often used in the rough separation and concentration, especially for the separation of tungsten ore, tin ore, gold ore and other dense metal minerals. The separating particle size of upper-moving diaphragm jig is 18-12mm to 0.2mm, it has a high enrichment ratio and large stroke coefficient. At present, this jigging machine has only one model of 300mmx450mm, with double jigging chambers connected in series. Generally, materials are sorted through the first jigging room, and then enter the second jigging room. During mineral separating, the two-chamber diaphragm alternately moves up and down.

(2) Down-moving conical diaphragm jig

Down-moving conical diaphragm jig is generally used to process coarse particles with a size of less than 6mm. Because its diaphragm located between the trough cone and the movable cone of the jig chamber, which can save power consumption and discharge large-density products smoothly. However, when the separation requirements for particles are wider, the recovery of coarse-grained minerals is poor.

(3) Lateral diaphragm jig

The working table of lateral diaphragm jig is trapezoidal with flexible configuration. The feed end is shorter and the row end is wider which is conducive to the recovery of fine-grained minerals, especially suitable for separating minerals and gangue minerals with high density and uneven mineral distribution. Lateral diaphragm jig sometimes used in the hematite and limonite separation.

02 Air Pulsating Jig

BackThe air pulsating jig is also called a pneumatic jigger, which is separating minerals by air compression. According to different air chamber positions, air pulsating jigs can be divided into sieve side air chamber (side drum type) jigs and under sieve air chamber jigs. The air pulsation jig is mainly used in coal processing.

03 Moving Jigger

BackMoving screen jigs can be divided into mechanical moving jigger and manual moving jigger by the various drive systems. Manual moving sieve jigs have basically been eliminated, while mechanical moving jiggers drive the sieve plate to reciprocate through hydraulic or mechanical force, which can sort the material on the sieve plate. This moving jigger is mainly used for large-scale coal beneficiation plant or coal processing plants in cold and water-deficient areas.

04 Related Matters in Application

BackThese are the classification of jigs and their suitable application scenarios. But when you choose a jig machine for ore dressing plant, you should pay attention to some matters as following:

(1) You need to conduct a beneficiation test to understand some conditions, such as the particle size range of the material, the monomer dissociation of useful minerals, and the particle size and density of the artificial bed.

(2) You need to consider the area of the jig room when designing the plant. When the area of the jigging chamber is large and the stroke coefficient is relatively small, if the supplemental water is insufficient or uneven, it may cause minerals on the bed harden.

(3) If the mineral contains a lot of heavy sand, it will be more difficult to separate, which may result in a decrease efficiency of the jig machine. You need to check whether multiple sand is deposited on the screen in time. If it occurs more heavy sand on the bed, you need to stop and remove the accumulated material in time;

(4) When the material contains primary slime or more secondary slime, you need to design a desliming stage for the beneficiation plants to obtain a better separation effect.

05To Wrap Up

BackIt is necessary to consider various factors when you choose jig machine and apply it. It is recommended that you need to select an equipment manufacturer with the qualification to build a beneficiation plant, and conduct beneficiation tests and designs in advance.

If you want to know more about jig machine or purchase it, welcome to submit a message or consult online service.

+86 18234403483

+86 18234403483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now