5 Q&A about Jig Machine You Need to Know!

Shirley

Shirley

Jan 05, 2023

Jan 05, 2023

2516

2516

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

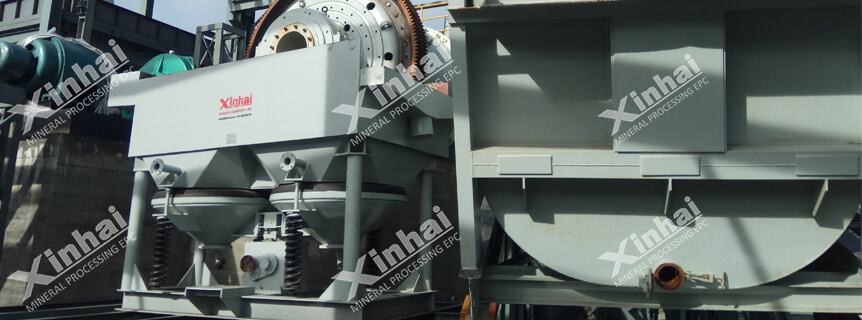

Jig machine refers to the equipment that realizes the jigging process. The material is mainly sorted according to the difference in density in the variable speed medium flow of vertical lifting. The difference in particle size and shape of materials has a certain influence on the beneficiation results. The medium used during jigging can be water or air. When water is used as the sorting medium, it is called hydraulic jigging. When air is used as the sorting medium, it is called wind jigging.

01What's the jig machine for?

BackThe jig machine is a fixed sieve type, suitable for sorting metal ores, such as tungsten-containing, gold-containing placer, selected tin ore, etc. It can be used not only for fine-grained materials, but also for coarse materials. The maximum feeding particle size is 6-8mm. However, in the individual cases of separating placer, the maximum particle size is 12mm.

02What's the working principle of jig machine?

BackThe jig belongs to the deep groove gravity separation equipment. All jig machines have a jig chamber. The operating mechanism and product discharge mechanism for agitating water movement. The jigging indoor sieve plate is made of punched steel plate, woven iron screen or grate. The water flow into the jigging chamber through the sieve plate should make the bed rise to a small height and be slightly loose. Particles with high density enter the bottom layer due to high local pressure and settling velocity, while particles with low density are transferred to the upper layer. When the water flow drops, the fine particles with high density can also enter the lower layer through the gradually tighter bed gap. The piston chamber is located beside the jigging chamber, and the lower part is connected, and the eccentric link mechanism drives the piston to move up and down.

03What are the types of jig machine?

BackVarious types of jigs are used at home and abroad, which can be roughly divided into the following types according to the equipment structure and water movement mode.

Piston jig

The piston jig is based on the reciprocating motion of the piston to generate a vertically rising pulsating water flow. It is an early type of jig and has basically been replaced by diaphragm jig and air pulse jig.

Diaphragm jig

The diaphragm jig uses a diaphragm instead of a piston. Most of its transmissions are eccentric linkages, and some use cam levers or hydraulic transmissions. The shape of the machine is mostly rectangular and trapezoidal, and circular has appeared in recent years. According to the installation position of the diaphragm, it can be divided into upper-moving type (also known as side-moving type), bottom-moving type and side-moving diaphragm jig. Diaphragm jigs are mainly used in metal ore beneficiation plants.

Air Pulse Jig

The water flow in the air pulsation jig (also known as the non-piston jig) is a vertical alternating motion, which is carried out by means of compressed air. According to the location of the air chamber of the jig, it is divided into a screen side air chamber (side drum type) and an under screen air chamber jig. This type of jig is mainly used for coal preparation.

Moving screen jig

There are two types of moving sieve jig machines: mechanical moving sieve and manual moving sieve, and manual is rarely used. The mechanical dynamic screen is a kind of water flow in the tank without pulsation, directly relying on the dynamic screen mechanism to hydraulically or mechanically drive the sieve plate to reciprocate up and down in the water medium, so that the materials on the sieve plate are periodically loosened. This type of jig is mainly used for lump coal discharge in large-scale coal preparation plants, especially in high-cold and water-scarce areas.

04What are the features of jig machine?

Back1. Adopt multi-chamber shared numerical control air valve technology.

2. The tapered slide valve is adopted, which is reliable in operation, the failure rate is reduced by 70%, and the energy consumption is small, which can meet the separation needs of different media and increase the processing capacity by more than 20%.

3. The structure is more reasonable, which is convenient for transportation and installation, and the equipment load is reduced by 30%.

4. The power is reduced by more than 70%.

05What are the influencing factors of jig machine?

BackFeeding amount

The selection and adjustment of the feeding amount is an important factor affecting the separation effect of the jig machine. The feeding amount should not be too small. If it is too small, not only the equipment capacity cannot be exerted, but also the loss will be increased and the quality will be deteriorated. However, it is not appropriate to feed too much, which will lead to the increase in the amount of coarse ore and the deterioration of the quality of the concentrate.

Air volume and water volume

During the jigging separation process, when the material is relatively stable, the parameters of the jig machine should be kept as stable as possible, so as to stabilize the separation effect. Among them, air volume and water volume are a very important factor. It not only determines the beating height (amplitude) of the bed, but also determines the mobility of the bed. The following points are worth noting about the coordination of air volume and water volume.

(1) There are many fine-grained materials in the raw materials. In this case, under the condition of ensuring that the raw coal is completely wet, the horizontal flushing water should be reduced as much as possible, and the amount of top water should be reduced room by room along the length of the jig. Large water and small wind are used at the front of the jig to prevent fine-grained materials from passing through the screen prematurely. The air volume can be increased in the middle of the jig, so that the fine-grained materials with poor quality are stratified and then discharged through the sieve.

(2) When the quality of the coarse-grained grade is good and the quality of the fine-grained grade is poor, the general method is to strengthen the sieve and enhance the suction force. The adjustment of air valve adopts the principle of short intake time, long exhaust time, large air volume and small water volume.

(3) The quality of the coarse-grained grade in the raw material is poor, and when the quality of the fine-grained grade is good, the through-sieve should be reduced, and heavy products are mostly discharged from the sieve. Therefore, the rising period should be strengthened and the falling period should be weakened. The adjustment of the air valve is generally a long intake time and a short exhaust time.

(4) When the particle size of the raw material is uniform and the quality is good, the operation system of small wind and big water should be adopted. When the particle size of the raw material is uniform and the quality is poor, the operation system of strong wind and small water should be adopted. The allocation of air volume and water volume is the dominant factor to ensure that the bed is sorted by density.

Emissions

When the feeding amount is stable, the air volume and water volume are used properly, and the stratification effect is good, the final result of the product depends on the product discharge system. Correct nesting is one of the important factors to ensure product quality.

The discharge volume of the main section should not be too large or too small. If the discharge is too large, it will increase the loss and make the bed too thin, causing the bed to be disordered and not conducive to separation. If the discharge volume is too small, it is easy to thicken the bed layer, and the bed layer cannot jump up with the same amount of wind and water, and the looseness is small. Therefore, the materials cannot be sorted well, which not only affects the product quality but also increases the loss. Furthermore, if the discharge is not timely, it is often easy to pile up coal. In this case, sometimes the gangue has to be discharged suddenly. Improper discharge in the first stage will not only increase the loss, but also affect the bed separation in the second stage. In the case of good discharge in the first stage, the discharge in the second stage should be as stable as possible. In short, pay attention to the reasonable coordination between the first and second stages in the discharge.

+86 182 3440 3483

+86 182 3440 3483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now