Antimony Mining Explained

Sheena

Sheena

Oct 13, 2025

Oct 13, 2025

828

828

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Antimony-mining

Antimony mining refers to the extraction of antimony-bearing ores, primarily stibnite (Sb₂S₃), from the Earth. These ores are processed to recover metallic antimony or antimony trioxide (Sb₂O₃), the most commercially important compound.

Global demand for antimony is rising, driven by the growth of renewable energy, electric vehicles, and advanced materials. As supply remains limited and geographically concentrated, antimony mining has become a strategic priority for both industrial and national security purposes.

01How Is Antimony Mined?

BackMining methods depend on ore depth, grade, and geological setting. The main approaches include:

(1) Open-Pit Mining

Used for near-surface deposits, open-pit mining involves drilling, blasting, and hauling ore to the surface. The advantage is lower capital cost and faster access to ore, though waste handling and environmental impact must be managed carefully.

(2) Underground Mining

Deeper or higher-grade stibnite veins are extracted through underground methods such as cut-and-fill, shrinkage stoping, or room-and-pillar. This method is more selective, reducing dilution and allowing recovery of narrow ore zones.

(3) Alluvial and Residual Deposits

In some tropical regions, weathered stibnite accumulates in secondary deposits. These can be mined by small-scale artisanal methods or mechanized washing plants.

02Ore Processing and Antimony Recovery

BackOnce mined, antimony ores undergo a series of beneficiation and metallurgical processes to extract the metal or its compounds. The main processing steps include:

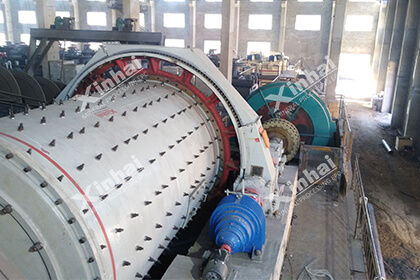

(1) Crushing and Grinding

The raw ore is crushed and ground into fine particles to liberate stibnite from gangue minerals.

(2) Gravity Separation

Since stibnite has a high specific gravity, gravity separation methods—such as jigs, shaking tables, and spiral concentrators—are commonly used for coarse particle recovery. This method is cost-effective and environmentally friendly.

(3) Flotation

For finer particles or complex ores, flotation is applied using collectors like xanthates. The process selectively separates stibnite from sulfide gangue minerals. This is the most widely used beneficiation technique for antimony ore.

(4) Roasting and Smelting

The concentrated stibnite is roasted to convert it into antimony trioxide (Sb₂O₃). The oxide can be reduced with carbon to produce metallic antimony:

Sb2O3+3C→2Sb+3COSb_2O_3 + 3C → 2Sb + 3COSb2O3+3C→2Sb+3CO

Modern smelters may use rotary kilns, blast furnaces, or reverberatory furnaces to achieve high recovery rates.

(5) Hydrometallurgical Processes

In some cases, leaching methods using alkaline or acidic solutions are employed to dissolve antimony selectively, followed by precipitation or electrowinning to recover the metal.

03Environmental and Safety Considerations

BackAntimony ores often contain arsenic and sulfur, making environmental management a key part of mining operations. Key concerns include:

Tailings management: Proper containment and water treatment are essential to prevent contamination.

Air emissions: Roasting and smelting can release sulfur dioxide (SO₂) and antimony oxides, requiring advanced filtration systems.

Worker safety: Antimony dust and fumes are toxic, so occupational exposure controls are critical.

Many countries now require environmental impact assessments (EIA) and strict compliance with international standards before approving new antimony mining projects.

04Future Outlook: Strategic Metal in Energy Transition

BackAntimony is now recognized as a critical mineral by the European Union, United States, and many other countries. It is essential for energy storage, electronics, and defense technologies.

As supply tightens, there's growing focus on:

Reprocessing tailings to recover residual antimony.

Developing eco-friendly hydrometallurgical methods.

Exploring new deposits in politically stable regions like Australia, Canada, and Africa.

Circular economy initiatives, including recycling from spent batteries and flame-retardant plastics.

With increasing geopolitical risks and limited global supply, antimony mining investments are expected to rise in the coming decade.

05Conclusion: The Growing Strategic Value of Antimony Mining

BackFrom traditional stibnite veins to advanced metallurgical processing, antimony mining remains vital to the global supply chain of critical materials. As industries shift toward sustainable technologies and supply diversification, the demand for reliable, environmentally responsible antimony production will continue to expand.

Investors and mining companies that adopt innovative extraction technologies and green processing methods will be best positioned to lead the next phase of the antimony mining industry.

+86 182 3440 3483

+86 182 3440 3483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now