Chrome Mining: Process, Equipment, and Investment Guide for 2025

Sheena

Sheena

Jul 17, 2025

Jul 17, 2025

2084

2084

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Chrome-Mining-Plant-Panorama

In this article, we will break down the chrome mining process, the types of equipment used, current market conditions, and key investment factors you should consider before starting a chrome mining operation. Whether you're planning a new project or expanding an existing one, understanding the full picture is essential.

01 What is Chrome Ore and Why Is It Valuable?

BackChrome ore (chromite – FeCr₂O₄) is the main source of chromium. Its unique resistance to heat, corrosion, and wear makes it essential in the production of:

Stainless steel (accounts for ~85% of chrome usage)

Foundry sands

Refractory materials

Pigments and electroplating chemicals

The main producers of chrome ore include South Africa (by far the largest), Kazakhstan, India, Turkey, and Zimbabwe.

02 Chrome Mining Process Overview

BackThe chrome mining process typically includes the following steps:

a) Exploration and Ore Body Evaluation

Geological surveys and sampling to locate high-grade deposits

Drilling and core logging to assess ore grade and volume

b) Mining Methods

Chrome ore is typically extracted using:

Open-pit mining: Suitable for shallow and near-surface deposits

Underground mining: Applied when the ore lies deep below the surface

Choice of method depends on ore body depth, geology, and economics.

c) Ore Transportation

Excavated ore is transported from the mine site to processing facilities using trucks, conveyors, or rail systems.

03 Chrome Ore Processing and Beneficiation

BackRaw chromite ore is rarely suitable for direct use. It requires processing to upgrade its Cr₂O₃ content and remove gangue minerals.

Key Processing Steps:

Crushing and Screening

Reduces large rocks into smaller particles for processing

Gravity Separation

Spiral concentrators, shaking tables, and jigs are used to concentrate heavier chrome particles

Magnetic Separation

Removes iron-bearing minerals

Flotation (Optional)

Applied for fine particle separation or low-grade ores

Dewatering and Drying

Final product is dewatered and dried for transport or sale

04 Chrome Mining Equipment You’ll Need

BackChrome ore beneficiation relies heavily on gravity-based equipment. Commonly used machines include:

| Jaw Crusher | Primary ore crushing |

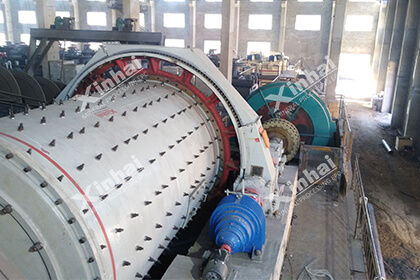

| Ball Mill or Rod Mill | Further size reduction |

| Spiral Concentrator | Chrome particle separation |

| Shaking Table | Fine-grain recovery |

| Slurry Pumps | Transporting pulp between stages |

| Magnetic Separator | Iron impurity removal |

| Dewatering Screen | Moisture reduction |

05 Chrome Mining Cost Analysis

BackThe cost of setting up and running a chrome mining operation varies depending on project scale, location, and ore characteristics. Here’s a general breakdown:

a) Capital Expenditure (CAPEX)

Small-scale plant (5,000–10,000 TPA): $3M–$10M

Mid-size plant (20,000–50,000 TPA): $10M–$50M

Large-scale operation (100,000+ TPA): $50M–$200M+

CAPEX includes exploration, mining equipment, beneficiation plant construction, utilities, and permitting.

b) Operational Costs (OPEX)

Labor

Electricity

Water supply and recycling

Consumables (grinding media, reagents)

Maintenance

Environmental and compliance costs

06 Chrome Ore Market Outlook for 2025 and Beyond

BackThe global chromium market is forecast to grow steadily due to:

Urbanization and infrastructure development

Stainless steel demand in China, India, and Southeast Asia

Tightening environmental regulations, increasing interest in efficient plants

Chrome ore prices are expected to remain stable, with occasional spikes due to logistics or geopolitical disruptions.

07 Common Questions About Chrome Mining

BackQ1: How long does it take to build a chrome beneficiation plant?

A: For a small-to-medium plant, 6–12 months from design to commissioning.

Q2: Can chrome ore be processed onsite at the mine?

A: Yes. Modular plants allow for near-mine beneficiation, reducing transport costs and improving efficiency.

Q3: Do you offer EPC (Engineering-Procurement-Construction) services?

A: Yes. We provide full turnkey solutions including design, supply, installation, and training.

08Conclusion: Start Your Chrome Mining Project

BackChrome mining offers significant profit potential, but success depends on careful planning, the right technology, and experienced partners. Whether you're developing a new mine or optimizing an existing operation, the right strategy can make all the difference.

+86 182 3440 3483

+86 182 3440 3483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now