The Ultimate Guide of Beneficiation Tailing Processing

Essow

Essow

Aug 29, 2022

Aug 29, 2022

1884

1884

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

After the ore is beneficiated, a large amount of tailings will be produced. It often also contains useful components that cannot be recovered at the current technical level. Flotation plant tailings contain a large number of chemicals, some of which are even highly toxic.

In order to comprehensively utilize resources and eliminate environmental pollution, effective measures must be taken to process tailings.

At present, a few "tailing-free" concentrators have appeared, whose tailings have been fully utilized. Turning waste into treasure and turning harm into profit is an important principle of tailings treatment.

The tailings facilities of the concentrator generally include a tailings storage system, a tailings conveying system, a backwater system and a tailings purification system.

The tailings storage system is the main body of the tailings facility. Tailings sedimentation pond and tailings dam are its main structures.

01 Tailings Sedimentation Pond

BackAccording to terrain conditions and construction methods, tailings sedimentation pools can be divided into three types:

1. Valley-Type Tailings Sedimentation Pond

This kind of tailings sedimentation pond is formed by closing the mouth of the river valley.

The advantages are that the dam body is short, the initial dam engineering volume is small, and it is easy to build the tailings dam during production.

The disadvantage is that the water accumulation area is large, so the flood volume flowing into the tailings sedimentation tank is large, and the drainage structure is complicated.

2. Beach-Type and Slope-Type Tailings Sedimentation Pond

Tailings sedimentation ponds built on river beaches or slopes are usually enclosed on three sides. The advantage is that the water accumulation area is small and the drainage structure is simple.

The disadvantage is that the dam is built on three sides, the dam body is long, the initial dam construction volume is large, and it is inconvenient to build the tailings dam during production.

3. Flat-Type Tailings Sedimentation Pond

This kind of sedimentation pond is formed by building dams on four sides on a flat ground.

The advantage is that the water accumulation area is small and the drainage structure is simple.

The disadvantage is that the dam is built on all sides, the dam body is long, the initial dam engineering volume is large, and the operation and management during production are inconvenient.

This type of tailings sedimentation tank is usually used when there is a lack of suitable river valleys, river beaches, slopes, or when the above two types of tailings sedimentation tanks are not suitable.

(Beach-Type Tailings Sedimentation Pond)

02 Tailings Conveying System

BackFor the tailings of the dry concentrator, generally, skips or mine cars, belt conveyors, aerial ropeways or railway trains can be used for transportation.

For wet concentrators, tailings are mostly discharged in the form of pulp, so hydraulic transportation must be used.

Common tailings conveying methods include gravity conveying, pressure conveying and combined conveying.

1. Gravity Conveying

Gravity conveying is to use the terrain height difference to make the tailings slurry of the dressing plant flow to the tailings sedimentation tank along the pipeline or chute. During self-flow conveying, the slope of the pipeline or chute should ensure that the solid particles in the slurry do not settle down. This method is simple and reliable and requires no power.

2. Pressure Conveying

Pressure conveying is a way of forcing the slurry to be lifted by means of a sand pump. Due to the limitation of the sand pump lift, it is often necessary to set up an intermediate sand pump station and a pressure pipeline for sectional lift, so it is more complicated. It can only be used in this way when it cannot be transported by gravity.

We have an article about common types of slurry pumps,please click the link to check it!

(Slurry Pump for Tailings Conveying)

3. Combined conveying

Combined conveying is a combination of gravity conveying and pressure conveying. If there is a height difference available in a certain section, it can be conveyed by gravity flow; if a section cannot use gravity conveying, it can be conveyed by a sand pump.

The tailings conveying system should have backup lines. In particular, regular maintenance should be carried out during pressure delivery. In order to cope with accidents, accident sedimentation tanks should be set up in certain areas.

03 Purification of Tailings Water

Back

The purification method of tailings water depends on the composition and quantity of harmful substances, the type of the water system in which the tailing water will be discharged, and the requirements for the quality of the backwater.

1. Classification of Tailings Water Purification Methods

It can be divided into three categories:

#1. Natural precipitation-use tailings sedimentation tanks (or other types of sedimentation tanks) to remove the tailings particles in the tailings liquid;

#2. Physical and chemical purification- use adsorbent materials to adsorb and remove certain harmful substances;

#3. Chemical purification-add appropriate amount of chemical agents to promote the conversion of harmful substances into harmless substances.

2. Treatment of Tailings Particles and Suspended Solids

The main method is to use the tailings sedimentation tank to precipitate the tailings water in the pond to achieve the purpose of clarification. If the particle size of tailings particles is extremely fine (such as tungsten-tin gravity separation tailings, some flotation tailings), the tailings water is often gelatinous, in order to quickly clarify the tailings water, we can add a coagulant (such as lime, aluminum sulfate, etc.) to accelerate the precipitation of particles.

For example, the tailings of a tin ore dressing plant have extremely fine particle sizes and cannot be clarified after 20 days and nights of precipitation. However, after adding 75 grams of lime solution with 40% active ingredient to each cubic meter of tailings water, the tailings can quickly settle, and after precipitation for about 2 hours, the transparency reaches 30 cm.

3. Purification Methods of Tailings Water

When the tailings water contains metal ions such as copper, lead, nickel, etc., we often use adsorption purification methods to remove them. Commonly used adsorbents are dolomite, roasted dolomite, activated carbon, lime and so on. Before purification, the adsorbent needs to be crushed to a certain particle size, and then fully mixed and reacted with the tailings water to achieve the purpose of sedimentation and purification of the tailings water.

Lead-zinc ore powder has the property of adsorbing organic agents, so it is often used to remove organic agents such as xanthate, black medicine, turpentine, and oleic acid. The dosage is 200 mg of lead-zinc ore per mg of organic chemicals.

When the tailings water contains single cyanide or double cyanide compounds, bleaching powder, ferrous sulfate and lime are generally used as purifying agents for chemical purification. Lead-zinc ore and activated carbon can also be used as adsorbents for adsorption purification.

In short, the purification method of tailings water is mainly selected according to the types of harmful substances contained in the tailings water and the degree of purification required. At the same time, consideration should be given to preferentially adopting methods with a wide range of purifier sources, simple processes, and cost-effective methods. The commonly used tailings water purification methods are summarized as follows:

Purification Method | Application Range |

Lime | Remove Copper and Nickel Ion |

Dolomite | Remove Lead Ion |

Roasted Dolomite | Remove Copper and Lead Ion |

Zinc and Lead Ore Powder | Remove Organic Flotation Reagent Remove Cyanide |

Bleaching Powder | Remove Cyanide |

Ferrous Sulfate | Remove Cyanide |

Activated Carbon | Adsorb Heavy Metal Ion Adsorb Cyanide |

(Tailings Water Purification Methods)

04 4. Reuse of Tailings Recycling Water

BackRecycling and reusing the tailings wastewater and keeping the proportion of wastewater recycling as high as possible to achieve the goal of closed-circuit circulation, is the focus of current wastewater treatment technology. Partial efflux is performed only when closed-circuit circulation cannot be achieved.

The tailings wastewater can be reused after purification, which can not only save the water source, reduce power consumption, but also solve the problem of environmental pollution.

Tailings water recycling generally has the following methods:

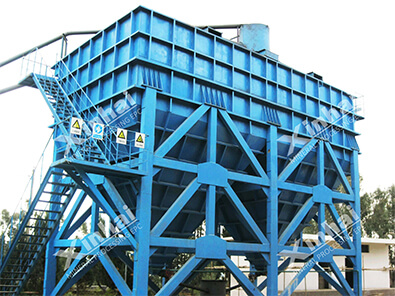

1. Using Thickeners to Recycle Water

Thickener is used to dewater the tailing liquid in or near the beneficiation plant, and the tailing sand is settled at the bottom of the thickener, and the clarified water is overflowed from the pond and sent back to the beneficiation plant for reuse. The return rate of the thickener is generally up to 40~70% or more.

Large beneficiation plants or gravity separation plants use thickener to recycle water. On the one hand, it can obtain a large amount of recycled water in the thickener, reduce the burden of water supply; on the other hand, using thickener could increase tailings concentration and reduce the flow of tailings liquid, so the cost of tailings transport can be reduced.

We have an article about thickener types and selection, please click the link to check it.

(Thickener in Gold Mine)

2. Using Tailings Sedimentation Ponds to Recycle Water

After the tailings are discharged into the tailings sedimentation pond, a part of the water contained in the tailings liquid remains in the voids of the deposited tailings, a part penetrates into the outside of the pond through the bottom of the dam body, and the other part evaporates on the surface of the pond. The recycling water of the tailings sedimentation tank is to recycle this remaining clarified water for use by the concentrator.

Since the tailings sedimentation pond itself has a certain catchment area, the tailings sedimentation pond itself plays a role in regulating the runoff water.

The return rate of tailings sedimentation pond is generally up to 50%. If the water source of the mining area is insufficient, but the tailings sedimentation pond has a large catchment area, and the mining area has good engineering geological conditions (such as no geological structure with serious water leakage such as karst caves and faults), the return water rate can be as high as 70~80%.

The advantages of the recycling water with the tailings sedimentation pond are: the quality of the recycling water is better, and part of the rainwater runoff is regulated in the tailings sedimentation pond, so the amount of return water sometimes increases.

The disadvantage is that the return water pipeline is long and the power consumption is large.

(Gold mine Tailings Sedimentation Pond)

3. Using Sedimentation Tanks to Recycle Water

The utilization of the backwater of the sedimentation tank is generally only applicable to small concentrators. Since the tailings sand deposited at the bottom of the pond needs to be removed frequently and requires a lot of manpower, it is not suitable to use the return water of the sedimentation tank when the production scale of the concentrator is large and the production period is long.

+86 182 3440 3483

+86 182 3440 3483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now