Low-Cost Electrowinning Solutions for Gold Mining Operations

Sheena

Sheena

Jul 21, 2025

Jul 21, 2025

1730

1730

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

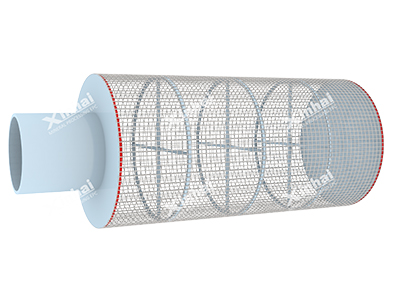

Gold-Desorption-Electrolysis-System

Electrowinning is a crucial step in the gold refining process, transforming dissolved gold from a leach solution into solid metal. This article explores affordable electrowinning solutions that reduce capital and operational expenses while maintaining efficiency and metal purity.

01 What Is Electrowinning and Why Is It Important?

BackElectrowinning is an electrochemical process that uses direct electric current to plate metals—such as gold, silver, or copper—out of a solution. In gold mining, it's typically applied after cyanide leaching or carbon-in-leach (CIL)/carbon-in-pulp (CIP) processes to recover gold from pregnant solutions.

Key Advantages:

Recovers gold directly from solution

Produces high-purity gold (up to 99.99%)

Can be scaled from pilot plants to full production facilities

However, traditional electrowinning systems can be costly, both in terms of equipment and electricity usage.

02 Cost Factors in Gold Electrowinning

BackUnderstanding the cost breakdown helps identify where savings can be made:

| Cost Component | Description |

|---|---|

| CapEx (Capital Cost) | Electrowinning cells, rectifiers, power supply, safety systems |

| OpEx (Operating Cost) | Energy consumption, electrode maintenance, consumables |

| Labor & Training | Skilled workers required for monitoring and maintenance |

| Electrode Replacement | Cathodes and anodes may corrode and need frequent replacement |

Typical Costs:

Small-scale system: $10,000 – $50,000

Medium-scale system: $50,000 – $250,000

Large-scale systems: Over $500,000

The key to lowering costs is finding a solution that balances initial investment with energy efficiency and durability.

03 Low-Cost Electrowinning Solutions

Back3.1. Modular Electrowinning Units

Modular systems are pre-assembled and easy to install, minimizing construction and setup costs.

Benefits:

Lower installation cost

Easy scalability

Minimal civil works

Suitable for remote or mobile gold recovery setups

3.2. Energy-Efficient Rectifiers

Switching to high-frequency or switch-mode rectifiers can cut energy costs by 15–30% compared to old transformer-rectifier setups.

Features to look for:

Adjustable voltage and current

Built-in safety interlocks

Remote monitoring capabilities

3.3. Optimized Electrode Materials

Instead of high-cost stainless steel or titanium, low-cost lead-based or carbon composite cathodes can be used in small-scale settings.

Tip: Use a mixed-metal oxide (MMO) anode coating to extend lifespan without major cost increases.

3.4. Batch-Based Systems

For artisanal or small-scale mines, batch electrowinning allows operators to treat gold-rich solutions in smaller quantities with compact systems, reducing idle energy costs.

3.5. Solar-Assisted Electrowinning

In areas with high solar potential, integrating solar panels with the electrowinning system helps offset electricity costs.

04 Process Optimization Tips

BackEven with low-cost systems, fine-tuning process parameters is key to maximizing gold recovery and minimizing costs.

4.1. Control Voltage and Current

Gold deposition is optimal between 2.5 – 4.0 volts

Excess voltage causes energy loss and impurities (sludge)

Use a current density of 10–25 A/m² for best results

4.2. Maintain Solution Conditions

Temperature: 20–40°C

pH: 10.5–12 (avoid acidic environments)

Cyanide concentration: 100–300 ppm

4.3. Clean Electrodes Regularly

Remove gold deposits to prevent passivation

Prevent buildup of manganese or other impurities

4.4. Automate Monitoring

Low-cost PLC controllers can track voltage, current, and gold deposition in real-time, reducing labor costs and human error.

05 Comparing Electrowinning to Other Recovery Methods

Back| Method | Cost | Recovery Rate | Suitability |

|---|---|---|---|

| Electrowinning | Medium | High (95–99%) | Leach-based systems |

| Merrill-Crowe | High | Very High | Large-scale with clear solution |

| Activated Carbon (CIP/CIL) | Medium | High | For low-grade ore pre-processing |

Electrowinning is ideal after cyanide leaching or elution from carbon, and is often the last step before smelting.

06Final Thoughts

BackFor gold mining operations aiming to reduce expenses without compromising recovery, low-cost electrowinning solutions offer a practical path forward. Whether you're operating a small-scale mine in Africa or piloting a plant in South America, modular, efficient, and affordable systems are now available to meet your needs. Contact our team for expert consultation on gold recovery circuits, system sizing, and supplier recommendations tailored to your ore and operation scale.

+86 182 3440 3483

+86 182 3440 3483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now