4 Methods of Gold Gravity Concentration Process

Laura

Laura

Nov 30, 2021

Nov 30, 2021

2360

2360

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Gravity concentration is one of the earliest methods of mineral concentration, and seperating gold by it has been widely used in placer gold and vein gold mineral processing plants. It has proved that the method of recovering gold by gravity method mainly includes four gravity concentration process methods.

Single gravity concentration process

Gravity concentration-amalgamation combined process

Gravity concentration-cyanidation combined process

Gravity concentration-flotation combined process

In this article, we will introduce the above four gravity concentration process methods in detail. let's start!

01 Single Gravity Concentration Process for Gold

Back1.1 Feature

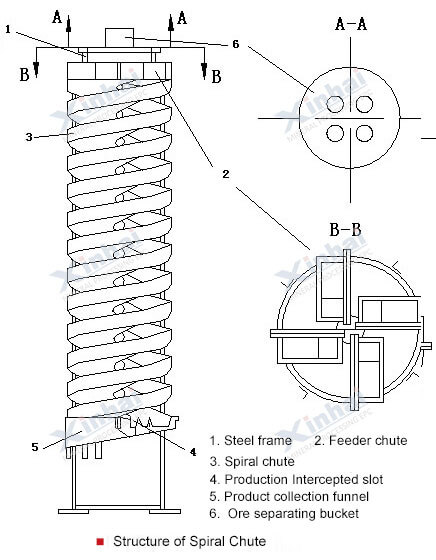

This process is relatively simple, which means that after crushed and ground, the chute is used to recover the gold. At present, Xinhai Mining mainly adopts spiral chute, which has 3 kinds to choose, including glass steel chute, Xinhai wear-resistant rubber liner, polyurethane rubber liner.

1.2 Application

Single gravity concentration process method is mainly used to select simple gold ores containing single gold, such as iron-bearing quartz vein type gold ores.

According to the particle size of the gold in the ore, one stage grinding or stage grinding is used. The stage grinding is generally used for gold ore with uneven distribution of the size of the gold.

02 Gravity Concentration-Amalgamation Combined Process for Gold

Back2.1 Feature

Gravity concentration-amalgamation combined process method is a typical process for processing high-grade vein gold ore in placer gold and small-scale beneficiation plants.

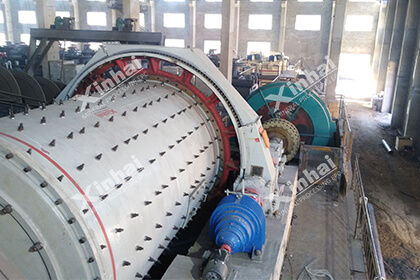

After crushed and ground, it passes through the chute for roughing, the chute tailings enter the classifier and the concentrate is then shaken into the shaker for selection, the shaker concentrate enters the amalgamation bucket, the shaker tailings and the classifier Return the sand, then use a ball mill to grind, the overflow of the classifier is discarded as tailings, the shaker concentrate is treated by amalgamation, and the mercury-containing mixture is classified for gold smelting. If the shaker concentrate is mostly concatenated gold, the coarse concentrate needs to be re-grinded, and then be selected with a shaker to obtain most of the shaker concentrate of single gold.

2.2 Application

Gravity concentration-amalgamation combined process method is only suitable for relatively simple gold ores, such as gold-bearing pyrite veins (gold-bearing quartz veins, in which gold is symbiosis with a small amount of pyrite, galena, sphalerite, etc.). The ore gold particles are relatively coarse, gold and a small amount of sulfide coexist, and the recovery rate of gold can generally reach more than 80%.

03 Gravity Concentration-Cyanidation Combined Process for Gold

BackAccording to the different exsiting status of gold in gold ore, this combined gold concentration process can be divided into two methods.

Gravity concentration-cyanidation of concentrate combined process

Gravity concentration-cyanidation of tailings combined process

3.1 Feature

Gravity concentration-cyanidation of concentrate combined process is to crush the ore, select the gold concentrate by gravity separation, and regrind the gold concentrate by cyanidation to recover the gold.

Gravity concentration-cyanidation of tailings combined process is to crush the gold ore, and use jigs or chutes in the classification loop to recover large particles of single gold or coated gold. When the classifier overflows, the heavy separation tailings will be cyanided. Then to recover the gold in the pulp.

3.2 Application

Gravity concentration-cyanidation of concentrate combined process is mainly used to process gold-bearing sulfide ores. The re-selection operation can be set in the circuit of grinding and classification to extract coarse-grained gold or gold-containing sulfides; the re-selection operation can also be placed after the overflow of the classifier, and the fine-grained gold or gold sulfide can be extracted with a shaker Connected organisms. This process can be used for general siliceous schist gold ore, conglomerate gold ore and quartz conglomerate gold ore.

Gravity concentration-cyanidation of tailings combined process is mainly used to process coarse-grained gold, which is suitable for refractory gold oxide ores that are suitable for cyanidation. It has the advantages of shortening the cyanide time, reducing the amount of cyanide, reducing the cost of cyaniding, and increasing the total gold recovery rate.

04 Gravity Concentration-Flotation Combined Process for Gold

Back4.1 Feature

The main feature of gravity concentration-flotation combined process is that it can handle ore pulp with a wide range of particle sizes, and does not need to be classified before sorting. It can comprehensively recover symbiotic minerals with a large proportion, which can effectively improve and increase the total recovery rate of gold.

4.2 Application

Gravity concentration-flotation combined process is widely used. It can not only process gold-bearing quartz vein sulfide ore, but also process gold-bearing polymetallic sulfide ore.

At present, Japan often uses a hydrocyclone to form a mixed-priority flotation process, that is, the rod mill discharges ore through a three-stage hydrocyclone for gravity separation to obtain a mixed coarse concentrate, and the coarse concentrate is combined with the flotation concentrate. After grinding, preferential flotation of polymetallic copper and zinc is carried out, and a good sorting effect is obtained. Typical South African gold ore also uses a combined process of gravity separation and flotation.

05To Wrap Up

BackIn this article, we mainly introduce the application of four gravity concentration process methods in gold mining, including single gravity concentration process, gravity concentration-amalgamation combined process, gravity concentration-cyanidation combined process, gravity concentration-flotation combined process. They are of great significance to the recovery of gold. In the next article, we will mainly introduce what type of gravity concentration process is suitable for different types of gold ore.

+86 182 3440 3483

+86 182 3440 3483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now