Gold-tailings-site

As the global mining industry pivots toward sustainable practices and resource efficiency, gold mine tailings reprocessing is rapidly gaining momentum. This innovative approach involves reprocessing tailings—the leftover materials from previous gold extraction—to recover remaining valuable metals using advanced technologies and equipment.

In this article, we will introduce the key technologies and equipment used in gold mine tailings reprocessing, examine their advantages, and explore why this process represents a transformative opportunity for both traditional miners and modern investors.

01Gold Mine Tailings Reprocessing Technologies

BackDifferent gold tailings require different reselection approaches depending on the mineral composition, size distribution, and historical processing methods. Below are the primary technologies used in tailings reselection:

1. Gravity Separation Technology

Best for: Coarse or free-milling gold particles remaining in tailings.

Overview:

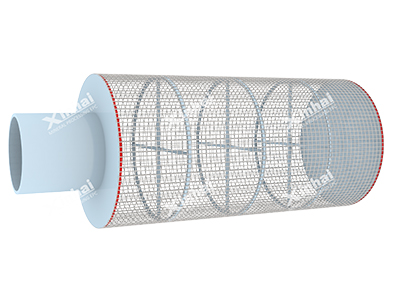

Gravity separation utilizes the difference in specific gravity between gold and gangue minerals. Equipment such as shaking tables, spiral concentrators, and centrifugal concentrators are widely used.

Advantages:

Environmentally friendly

No chemicals required

Low energy consumption

Simple to operate

Common Equipment:

Shaking Table

Knelson Concentrator

Falcon Concentrator

Spiral Chute

2. Flotation Technology

Best for: Sulfide-associated gold or fine gold particles embedded in mineral matrices.

Overview:

Flotation involves using air bubbles and reagents to separate gold-bearing sulfide minerals from the rest of the material. It’s particularly effective for tailings where gold is encapsulated in pyrite or arsenopyrite.

Advantages:

High recovery rate for sulfide gold

Good for ultra-fine gold

Can be used in multi-stage circuits

Common Equipment:

Flotation Cells (mechanical/agitation type)

Air-inflation Flotation Machines

Flotation Columns

3. Cyanidation (Leaching) Technology

Best for: Tailings with recoverable free or chemically liberated gold.

Overview:

Cyanide leaching dissolves gold in a solution, which is then recovered using activated carbon or zinc precipitation. While effective, this method requires strict environmental controls due to cyanide's toxicity.

Advantages:

Proven technology

High recovery for free and some refractory gold

Easily scalable

Common Equipment:

Leaching Tanks (CIL/CIP)

Thickening Tanks

Desorption Electrolysis System

Cyanide Detoxification Unit

4. Bioleaching and Bacterial Oxidation

Best for: Refractory tailings with sulfide-locked gold.

Overview:

Bioleaching uses naturally occurring bacteria to break down sulfide minerals, releasing encapsulated gold. It is a low-energy, eco-friendly solution for complex ores.

Advantages:

Low cost

Environmentally benign

Effective for refractory gold ores

Common Equipment:

Bio-reactors

Agitated Tanks

Heap Bioleaching Systems

02Supporting Equipment in Tailings Reselection Plants

BackIn addition to core separation technologies, a complete tailings reprocessing plant requires supporting equipment such as:

Dewatering Screens and Thickeners: For solid-liquid separation.

Tailings Conveyors and Pumps: For transport of material within the plant.

Dust Collection Systems: Especially important in dry environments.

Monitoring and Automation Systems: For real-time performance tracking.

03Factors to Consider Before Tailings Reselection

Back1. Tailings Composition Analysis

A detailed geochemical and mineralogical analysis is essential to determine the gold content, grain size, associated minerals, and possible environmental hazards.

2. Processing Technology Selection

Choosing the right reselection process depends on ore type, gold particle size, mineral associations, and prior treatment history.

3. Economic Feasibility Study

Investors and operators should conduct a comprehensive cost-benefit analysis, including capital costs, operational costs, metal recovery rates, and expected revenue.

4. Environmental and Legal Permitting

Ensure compliance with local regulations on water usage, chemical handling, and tailings disposal. Environmental impact assessments (EIAs) are often required.

04Conclusion: A Sustainable Future for Mining

BackGold mine tailings reselection represents a smart, sustainable, and scalable approach to resource recovery. With a wide range of proven technologies and specialized equipment, mining companies can turn historic liabilities into economic and environmental assets.

As gold prices remain robust and regulations tighten, reprocessing tailings is no longer a niche—it's becoming the new norm in modern mining.

Whether you're a mining engineer, investor, or sustainability strategist, gold tailings reprocessing offers a unique opportunity to maximize recovery, minimize impact, and future-proof mining operations.

+86 183 3575 8886

+86 183 3575 8886 pinklaurabao@gmail.com

pinklaurabao@gmail.com

Sheena

Sheena Jun 12, 2025

Jun 12, 2025 1767

1767 Message

Message Chat Now

Chat Now