How to Extract Graphite? | 7 Graphite Processing Methods

Shirley

Shirley

Nov 29, 2022

Nov 29, 2022

3855

3855

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

(Vietnam graphite processing plant)

Graphite is often combined with quartz, illite, kaolinite, rhodochrosite, sericite, and small amounts of pyrite, limonite, tourmaline, and calcite, which needs to purify and beneficiate before application. Graphite beneficiation solutions mainly include flotation separation, gravity separation, electro separation, selective flocculation, alkali-acid, acid leaching, chlorination roasting, and high-temperature roasting.

Among them, flotation separation, gravity separation, and electro separation are commonly used for graphite beneficiation processes, while alkali-acid, chlorination roasting and high-temperature roasting methods are used for further processing of graphite concentrates.

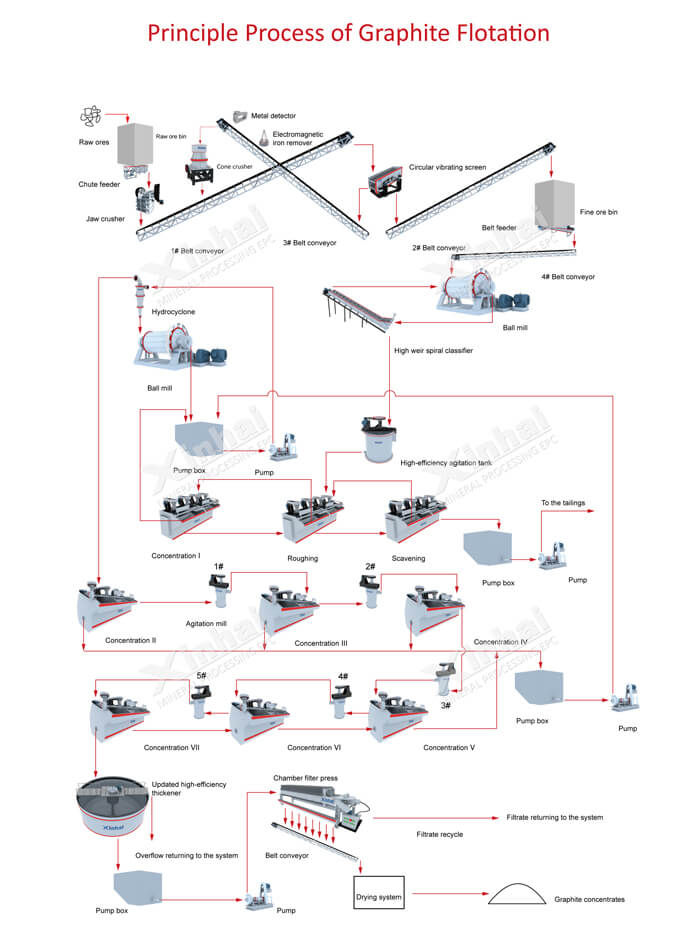

01 Graphite Flotation Separation Method

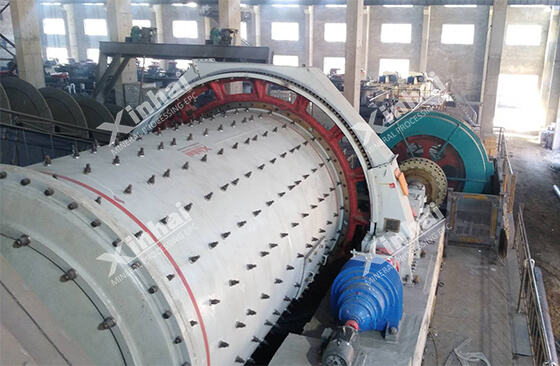

BackGraphite has good natural floatability and hydrophobicity. Therefore, most processing plants use flotation to purify graphite ore, which means adding a series of flotation chemicals to enrich the graphite ore in the gas-liquid interface for the separation from impurity minerals. The commonly used collector is coal tar. Pine oil or butyl ether oil are mainly used as the frothing agent, and the inhibitor agent mostly uses water glass and sodium fluorosilicate.

The flotation process of flake graphite ore mostly adopts multi-stage grinding, multiple separation, coarse concentrate re-grinding, and then separation process flow to protect the flake.

Graphite flotation separation can beneficiate the graphite grade reaching 80%~90% or even to almost 95%. And the method has been found to feature with low chemical consumption, low energy consumption, and low cost. But for graphite ore with very fine silicate minerals and compounds of potassium, calcium, sodium, magnesium, aluminum, and other elements, the grinding stage cannot achieve monomeric dissociation which needs to be purified again using other processes following the flotation method.

02 Graphite Gravity Separation Method

BackGraphite gravity separation is carried out according to the gravity difference between graphite ore and gangue. The symbiotic minerals in graphite ore can be divided into heavy minerals, medium gravity minerals and light minerals according to their gravity. Among them, heavy minerals (gravity>3.32) mainly include pyrite, pyrrhotite, limonite, zoisite, etc., followed by sphene, zircon, white titanium, monazite and scheelite. Medium gravity minerals (gravity among 2.9-3.32) mainly include diopside, tremolite, and occasionally apatite. In light minerals (gravity<2.9), there is a difference in the gravity of graphite and its symbiotic minerals. Therefore, heavy minerals can be separated by gravity separation to obtain coarse concentrates dominated by the graphite.

03 Graphite Electric Separation Method

BackElectric separation is a physical separation method that uses different electrical properties of various minerals and materials for separation. For graphite ore beneficiation, graphite ore has good electrical conductivity, while gangue minerals such as feldspar, quartz and pyrite have poor electrical conductivity. Based on this difference, graphite and other minerals can be separated by electric separation.

The effective processing particle size of the electric separation method is usually 0.1-2mm. But for flake or low-density graphite ore, the upper limit of the processing particle size can reach to 5mm. While the processing particle size of the wet high-gradient electric separator can be reduced to the micron level.

04 Graphite Selective Flocculation Method

BackTo purify graphite ore by selective flocculation method, it is necessary to add a polymer flocculant to a suspension containing two or more components, so that the flocculant can selectively adsorb a certain component in the suspension and produce flocculation precipitation via the bridge chain action to achieve the purpose of component separation.

In production practice, the commonly used flocculants are mainly sodium silicate, sodium hexametaphosphate, lignin starch, carboxymethyl cellulose, and the dispersant is mainly water glass.

The graphite ore purification with selective flocculation and equipment is relatively simple and low cost, but the fixed carbon recovery rate is low, which is only about 40%.

05 Graphite Alkaline Acid Method

BackAcid-alkali purification of graphite ore is a relatively mature method, which can be divided into two processes: alkali fusion and acid leaching.

Alkali fusion process: under high temperature conditions, the alkali in molten state chemically reacts with acid impurities (silicate, aluminosilicate, quartz) in graphite to form soluble salt, and then the impurities are removed by washing.

Acid leaching process: Use acid to react with metal oxide impurities to convert some of the impurities that did not react during the alkali fusion process into soluble salts, and then wash the impurities to separate them from graphite to improve the purity of graphite.

The grade of graphite can reach 99.5% by alkali acid method. The advantages of the method are simple equipment, low energy consumption and little one-time investment. However, the acid-base of this method still has some disadvantages, including strong corrosiveness to the equipment, the purified wastewater seriously polluted, and graphite loss problem.

06 Graphite Chlorination Roasting Method

BackThe graphite chlorination roasting method is mainly to add an appropriate amount of reducing agent into the graphite ore, and then roast it at high temperature in a specific atmosphere and equipment. After the valuable metal in the mineral combines with chlorine, it will be transformed into gas phase or condensed phase metal chloride with low melting point and boiling point, so as to separate effectively from other components and obtain high purity graphite.

Chlorination roasting method has the advantages of high efficiency, low energy consumption and low cost in purifying graphite ore. However, the chlorine gas in this method is highly corrosive and toxic, causing great environmental pollution.

07 Graphite High Temperature Roasting Method

BackThe melting point of graphite ore is very high (melting point of 3652 °C, boiling point of 4250 °C), which is much higher than other impurity minerals. Graphite high temperature roasting method is to use the melting point difference between graphite and other impurity minerals for separation. The graphite ore is heated to 2700~3000℃ with most of the impurities been vaporized, so graphite and impurities can be effectively separated.

High temperature roasting method to purify graphite ore can achieve a grade of 99.99% or even higher, but it still has some disadvantages, such as high energy consumption, high equipment requirements and required purity of the raw graphite ore.

08To Wrap Up

BackThe above introduces the 7 graphite processing methods. It is suggested to make suitable methods according to the mineral processing test result.

If you have other questions or want to customize your graphite beneficiation method for your graphite processing plant, you can contact the online service or submit a message. We will contact you soon.

+86 182 3440 3483

+86 182 3440 3483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now