How Much does it Cost to Build a Mica Processing Plant?

Sheena

Sheena

Aug 13, 2025

Aug 13, 2025

1357

1357

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Mica-flotation-plant

This article provides a comprehensive investment guide for mica processing plants, including price ranges for different plant sizes, key processing technologies, and factors affecting costs. Whether you are planning a small-scale plant for local markets or a large industrial facility for export, understanding the economics and technical requirements is essential.

01Mica Processing Overview

BackThe goal of mica processing is to extract high-purity mica flakes or powder from raw ore while minimizing waste and optimizing recovery.

Typical Mica Processing Steps

Mining

Crushing and Screening

Gravity Separation

Froth Flotation

Magnetic Separation (Optional)

Drying and Grinding

Classification and Packaging

Open-pit or underground mining depending on deposit depth.

Selective mining to reduce contamination from host rock.

Jaw crushers or hammer mills reduce ore size.

Vibrating screens classify particles by size.

Spiral concentrators, shaking tables, or hydrocyclones separate mica from heavier gangue minerals.

Fine mica is separated from quartz and feldspar using cationic collectors.

Removes iron-bearing impurities for higher purity grades.

Rotary dryers remove moisture.

Pulverizers produce fine mica powder.

Air classifiers separate fine and ultra-fine grades.

Bagging for shipment to end-users.

02Types of Mica Processing Plants

BackPlant design depends on target product (flakes or powder), ore quality, and production capacity.

| Plant Type | Main Product | Typical Capacity | Key Equipment |

|---|---|---|---|

| Small-Scale Manual Processing | Mica flakes | <100 t/day | Small crushers |

| Medium-Scale Mechanical Plant | Flakes & powder | 100–1000 t/day | Crushers, screens, gravity separators, dryers |

| Large Industrial Plant | High-purity powder | >1000 t/day | Automated crushing circuits, flotation cells, magnetic separators, micronizers |

03Mica Processing Plant Cost

BackThe cost of setting up a mica processing plant varies widely depending on capacity, degree of automation, location, and raw material source.

1. Small-Scale Plant Cost

Capacity: <100 t/day

Investment Range: $200,000 – $800,000

Suitable for: Artisanal mining regions, local supply markets.

Features: Manual sorting, simple crushers, basic drying.

2. Medium-Scale Plant Cost

Capacity: 100–1000 t/day

Investment Range: $1.5 million – $5 million

Suitable for: Regional markets and industrial suppliers.

Features: Full crushing, gravity separation, flotation, drying, and packaging lines.

3. Large-Scale Industrial Plant Cost

Capacity: >1000 t/day

Investment Range: $8 million – $25 million+

Suitable for: Export-grade products and specialized high-purity markets.

Features: Automated process control, advanced magnetic separation, ultrafine grinding.

04Key Factors Affecting Mica Processing Plant Cost

BackOre Quality and Mineralogy

Processing Technology

Production Capacity

Automation Level

Location and Logistics

Energy and Water Supply

High-grade deposits reduce beneficiation steps and operating costs.

Impurities (iron, quartz) increase processing complexity.

Advanced flotation and magnetic separation systems improve purity but increase CAPEX.

Higher capacity plants benefit from economies of scale but require higher initial investment.

Automation reduces labor costs but increases equipment cost.

Proximity to mines lowers transport costs.

Export facilities require compliance with additional quality standards.

Processing is energy-intensive; reliable power is critical.

Water recycling systems reduce operating costs.

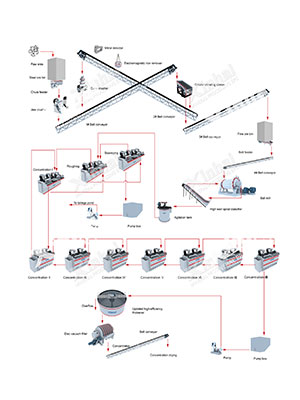

05Mica Processing Flow Sheet (Example)

BackOre Feed → Primary Crushing → Screening → Gravity Separation → Flotation → Magnetic Separation → Drying → Grinding → Classification → Packaging

This flowsheet can be adapted depending on whether the plant focuses on mica flakes or ultrafine powder.

06Reducing Investment and Operating Costs

BackModular Plant Design: Start with a smaller core processing line and expand later.

Equipment Sourcing: Consider refurbished or locally manufactured machinery for lower CAPEX.

Process Optimization: Adjust grind size and separation parameters to improve recovery.

Energy Efficiency: Use variable frequency drives (VFDs) and heat recovery systems.

Waste Management: Sell by-products like quartz or feldspar to offset costs.

07Conclusion

BackInvesting in a mica processing plant can be a profitable venture, especially as demand grows in high-tech, automotive, and renewable energy industries. The cost of a mica processing plant ranges from $200,000 for small-scale operations to over $25 million for large industrial facilities, depending on capacity, technology, and product specifications.

Choosing the right processing method—gravity separation, flotation, magnetic separation—will directly affect both the capital investment and the final product quality. Careful feasibility studies, ore testing, and market analysis are essential for ensuring project success.

+86 182 3440 3483

+86 182 3440 3483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now