How to Extract Tin from Ore?

Star

Star

Nov 06, 2022

Nov 06, 2022

1475

1475

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

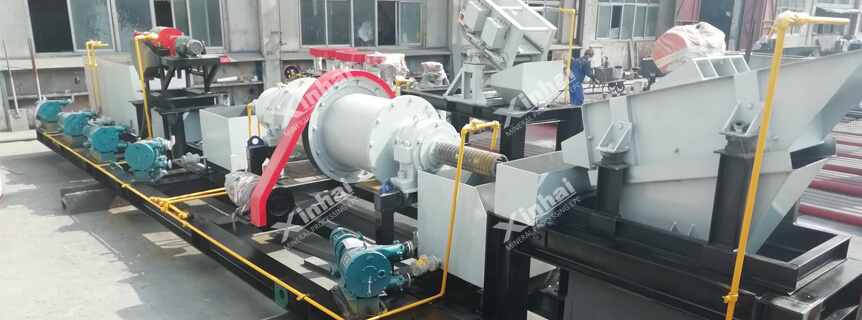

(2tpd tin ore mobile processing plant)

Tin ore is mainly divided into alluvial tin ore and vein tin ore. This article will introduce you how to extract tin from ore.

01The beneficiation method of tin sand ore

BackAlluvial tin deposits are mainly divided into two types: alluvial sand and residual slope sand. There are some differences in the beneficiation process of the two placers.

1. Mineral processing of alluvial tin ore

Almost all tin in alluvial tin ore exists in the state of cassiterite, with low tin grade, good dissociation degree of ore monomer, and mainly medium grains, usually accompanied by a variety of metals. The beneficiation feature of this kind of ore is that before the beneficiation, the waste rock without ore is removed in advance with a screening machine, and the ore is washed and deslimed as much as possible. The basic monomers of useful minerals are dissociated, so the raw ore does not need to be crushed and ground, but directly adopts graded roughing and concentrated selection.

The beneficiation process is: use crushing and screening to remove the waste rock without ore, and the ore is divided into +0.074mm and -0.074mm grades. The +0.074mm particle size can be sorted by a spiral concentrator or jigging or shaking table, and the -0.074mm particle size can be sorted by shaking table after removing the sludge.

(Shaking table)

2. Mineral beneficiation of residual slope sand tin ore

Cassiterite has fine grain size and uneven distribution; the ore contains high iron, and the tin and iron are closely combined; the weathering degree is heavy, and the mud content is large; there are many kinds of metal minerals associated with them, but the content is low. In beneficiation, we should try our best to ensure the dissociation of cassiterite monomers and prevent ortho-cassiterite from being over-crushed, and adhere to the principles of rich and poor separation, difficult and easy separation, coarse and fine separation, and the principle of getting it as soon as possible, and throwing it away as soon as possible.

Its principle process consists of four parts: washing and mud sand separation system, ore sand system, re-election system and ore slime system.

The ore sand system adopts a stage grinding-stage sorting process, and most of the concentrators use three-stage grinding-three-stage sorting. The ore feeding and re-selecting system in the shaking table of the ore sand system is processed. The complexity of the process of the re-election system depends on the content of iron and tin in the original ore. The simple process of "pre-reelection, one-stage grinding, and one-stage sorting" or "pre-reelection, second-to-three-stage grinding, and two-stage separation" can be adopted respectively.

It is a more complex process from three-stage separation, separate treatment of cover flow, and tailings sweeping. The main sorting equipment of the ore sand system and the re-election system is the shaking table. Primary slime and secondary slime are removed by hydrocyclone to remove -19um slime, and 37~19um fine slime is sent to the slime system, which is roughed by centrifugal concentrator first, and then concentrated by chute. The final tailings are swept with a shaker.

02The beneficiation method of vein tin ore

BackAt present, there are three types of vein tin ore: cassiterite-oxide ore, tin-tungsten quartz vein ore and cassiterite-sulfide ore, among which cassiterite-sulfide ore is the most important.

1. The beneficiation of cassiterite-oxidized ore

The beneficiation process of cassiterite-oxidized ore is similar to that of residual sand tin ore. It adopts a single gravity separation process based on shaking table, stage grinding-stage separation.

Concentration is a combined process including flotation, gravity separation, magnetic separation, and gravity separation, in order to obtain qualified tin concentrate, wolframite concentrate and scheelite concentrate.

2. The beneficiation of cassiterite-sulfide ore

There are many kinds of useful minerals in cassiterite-sulfide ore, and the useful minerals are closely symbiotic. In order to recover the valuable elements to the greatest extent, it is advisable to adopt a complex process that focuses on gravity separation and combines a variety of beneficiation methods. According to the mineral composition and embedded particle size of the ore, the beneficiation processes adopted include gravity separation-flotation process, gravity separation-flotation-gravity process, flotation-magnetic separation-gravity process, and flotation-gravity-flotation process.

The concentrate obtained by gravity separation is continue desulfurized by flotation, and then the final tin concentrate is obtained.

For cassiterite-sulfide ore with fine-grained cassiterite inlaid and complex mineral composition, the ore is first ground to a particle size that can be flotated. During flotation, the sulfide is first floated, and the obtained flotation tailings are then processed by gravity method to recover tin.

For the cassiterite-sulfide ore with uneven distribution of cassiterite and complex mineral components, the ore is coarsely ground and classified, and the coarse-grained grade is re-selected first and then flotated.

If the content of cassiterite is low and the content of associated minerals is high, the flotation-gravity process should be used.

If cassiterite and sulfide ores are inlaid in aggregates, they should be pre-selected (such as hand-separation, photoelectric beneficiation or heavy-medium beneficiation) under the appropriate crushed ore size, or re-separated first under rough grinding conditions, and then re-separated coarse concentrate and then re-selected. After grinding, it is separated by flotation or other methods.

If the ore contains a large amount of magnetic minerals or large-density oxides (such as calcium, tantalum and niobium minerals), it should be separated from cassiterite by magnetic separation or other beneficiation methods at appropriate positions in the process.

03Separation of cassiterite from other minerals

BackTin ore contains a variety of associated components, which can be used as polymetallic symbiotic ore in terms of development. Because these valuable components tend to be densely combined, it is difficult to use traditional gravity separation methods to fully work. It is necessary to vigorously adopt a variety of methods to combine beneficiation and a new process of combined selection and treatment.

1. Separation of cassiterite and sulfide

The most common sulfides in tin ore are pyrite, pyrrhotite, and arsenopyrite, as well as chalcopyrite, galena, sphalerite, pyrite and pyrite. The floatability of sulfide is much higher than that of cassiterite. Generally, particle flotation and froth flotation are used to separate sulfide and cassiterite. In flotation, copper sulfate is used as activator, xanthate is used as collector, and pine alcohol oil is used as foaming agent. If after flotation, the sulfur grade of tin concentrate is still at 1%, consider using boiling furnace, grease furnace or rotary dew melting, the melting temperature is 800~1000℃, and 6%~12% reducing agent is added to crush coal.

(flotation machine)

2. Separation of cassiterite and tungsten minerals

Wolframite is a weakly magnetic mineral, while cassiterite is generally non-magnetic and can be separated in a strong magnetic field. The magnetic field strength of magnetic separation wolframite is 0.5~0.81. The density and permeability of cassiterite and scheelite are similar, but the conductivity and floatability are different. Cassiterite has good conductivity and can become a conductive product in an electrostatic field. Using this feature, it can be separated from non-conductive scheelite.

When the adhering water content of the feedstock for electrostatic separation is less than 1%, it can be heated to 105-150℃ first to improve the beneficiation effect. The scheelite has good floatability, and can be separated from the unfloated cassiterite as a floating substance under normal flotation conditions. During flotation, add sodium carbonate or common sodium to adjust the pH of the pulp to 9~10, suppress cassiterite, cobalt and calcite with water glass, and use oleic acid or oxidized paraffin soap as collectors.

Due to the close symbiosis of tin and tungsten, some tin and tungsten refractory ores are difficult to be separated by mechanical beneficiation methods. Soda smelting and diffusion method can be used to generate artificial scheelite concentrate and tin concentrate. Fine-grained tin and tungsten can be separated by flotation. Using oxalic acid as the inhibitor of Heihe ore, mixed with toluic acid as cassiterite extraction agent, flotation of coarse concentrates containing 28% tin and WO.40% to obtain tin concentrates containing 69%~75% tin, WO. 0.8% 1.3%, tin recovery rate 92%~97%: Crane concentrate contains WO63%~69%, tin content is less than 1%, WO, recovery rate is 91%~95%. Sulfuric acid and sodium fluoride can also be used to inhibit cassiterite, and Elso-22 (yellow succinic acid amide tetrasodium salt) is used as a collector to flotate Heihe ore, and the tin concentrate contains 72.46% tin and WO.1.95%. : Crane concentrate contains WO.68.07% and tin 2.21%. 3. Separation of cassiterite and lead minerals

There are two flotation methods for cassiterite and zirconium oxide minerals: use vulcanizing agent to sulfide lead oxide minerals, and then add xanthate collector to flotate lead: tin concentrates with low lead oxide content (Pb3%~5%) can be directly reduced Smelting; tin concentrate with high lead content, as long as the content of tin and lead is higher than 50%, it can also be directly reduced and smelted, and refined tin and solder products can be obtained through roughing and refining.

3. Separation of cassiterite and tantalum-niobium minerals

There are differences between cassiterite and various tantalum-niobium minerals in density, specific magnetic susceptibility and floatability, but the difference is not large. Therefore, a combined beneficiation process is often required. For example, gangue minerals with low density are separated by gravity separation, ilmenite, magnetite and chernosite are removed by magnetic separation, non-conductive zirconite, monazite and phosphorite are removed by electrostatic separation, and hydrogen is removed by acid washing. Iron oxide.

4. Separation of cassiterite and ilmenite

The specific magnetic susceptibility and density of cassiterite and ilmenite are quite different, and magnetic separation and gravity separation are mainly used for separation. First, weak magnetic separation is used to separate magnetite, then strong magnetic separation is used to separate ilmenite into magnetic products, cassiterite enters non-magnetic products, and finally cassiterite concentrate is obtained by gravity separation or electrostatic separation according to the properties of other minerals. mine.

5. Separation of cassiterite and zircon

For the sorting of coarse-grained cassiterite and zircon, electrostatic separation is effective, cassiterite enters the conductive product, and zircon becomes the non-conductive product. In order to improve the effect of electrification, the ore will be heated to 80~120℃ during electrification. For fine-grained zircon, it can be separated by flotation, using oleic acid and kerosene (amount ratio of 1:1) as collectors, using sodium carbonate to adjust the slurry to alkaline, using starch to inhibit cassiterite, and flotation of zircon.

04To wrap up

BackThe above is a detailed introduction to how to extract tin from ore. Among them, tin ore gravity separation is still the main method for cassiterite recovery due to the advantages of low beneficiation cost, no environmental pollution, and high-quality tin concentrate can be obtained. Mine owners can comprehensively consider the properties of their own ore and choose the most suitable process method to maximize the beneficiation benefits.

+86 183 3575 8886

+86 183 3575 8886 pinklaurabao@gmail.com

pinklaurabao@gmail.com

Message

Message Chat Now

Chat Now