Iron Mine Automatic Control System Case

Essow

Essow

Feb 24, 2023

Feb 24, 2023

1692

1692

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Mineral dressing automation plays an important role in stabilizing the mineral processing production process, improving the technical and economic indicators of mineral processing, improving operating conditions, reducing labor intensity and ensuring safe production. The degree of automation of mineral processing is an important indicator to measure the degree of modernization of mineral processing plants. Here is a case of iron mine automatic control system.

01 Basic Automation System

BackThe basic automation system includes 6 sub-systems, namely, raw material screening and conveying control sub-system, ore conveying and dry separation control sub-system, shaft furnace roasting control sub-system, strong magnetic separation control sub-system, weak magnetic separation control sub-system and concentration and dewatering control sub-system. It realizes the logical control of starting, stopping, interlock protection, hopper blockage and motor overload fault alarm of 525 production equipments in the whole plant.

1. Raw Material Screening and Conveying Control Subsystem

According to the ore bin level setting, the relevant equipment is automatically started and stopped to realize the automatic feeding of lump and powder ore after the first and second screening of raw materials, and the automatic discharge of waste rock.

(Crushing and Screening Automatic System)

2. Ore Conveying and Dry Separation Control Subsystem

It realizes the automatic feeding of 10 small lump shaft furnaces and 4 rebound shaft furnaces and the automatic feeding of 4 round simple ore bins with weak magnetism.

3. Shaft Furnace Roasting Control Subsystem

The measurement of heating zone temperature, combustion chamber temperature, reduction zone temperature, water tank beam temperature and exhaust gas temperature at the top of the furnace, the measurement of pressure and flow of reduction gas, heating gas and heating air, the measurement of negative pressure at the top of the furnace and the heating gas calorific value, and the detection of the electric current of each moving out machine are realized for 22 100 cubic meters roasting shaft furnaces. It realizes the control of anti-pressure and removal time of the removal machine, and the closed-loop control of combustion chamber temperature and reduction gas flow.

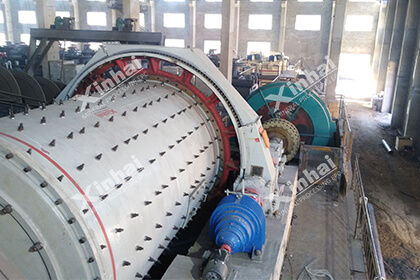

4. Strong Magnetic Separation Control Subsystem

It realizes the detection of the operation status of 8 ball mills in the first and second section of strong magnetic, the signals of stator current, shaft temperature and thin oil pump operation status, the detection of overflow concentration of classifier motor current, the detection of ore feeding pressure, flow rate, concentration of hydrocyclone, the detection of inlet water of one section of ball mill and ore feeding volume of one section of ball mill, the detection of liquid level of hydrocyclone feeding pump pool, the detection of flow rate, pressure, excitation current and temperature of rinsing water of 10 strong magnetic separators. pressure, excitation current and excitation coil temperature of 10 strong magnetic separators.

The closed-loop control of hydrocyclone feed pressure and concentration and pump pool level, the closed-loop control of ball mill feed volume and classification overflow concentration, and the closed-loop control of excitation current and rinsing water of the strong magnetic separator are realized to control the grade of magnetic separation concentrate.

5. Weak Magnetic Separation Control Subsystem

This subsystem complete the detection of the operation status, stator current, shaft temperature, thin oil pump operation status and other signals of the first and second weak magnetic ball mill and the detection of the classifier motor current and overflow concentration; the detection of the feeding pressure, flow rate, concentration of the hydrocyclone, the inlet water of one section of the ball mill and the feeding volume of one section of the ball mill, and the detection of the liquid level of the hydrocyclone feeding pump pool, realizing the closed-loop control of the hydrocyclone feeding pressure and concentration and the control of the liquid level of the pump pool. The closed-loop control of hydrocyclone feed pressure and concentration and pump pool level, and the closed-loop control of ball mill feed volume and classification overflow concentration are realized.

6. Thickening and Dewatering Control Subsystem

This subsystem realized the detection of the bottom flow dependence of 5 thickeners and the closed-loop control of the bottom flow concentration.

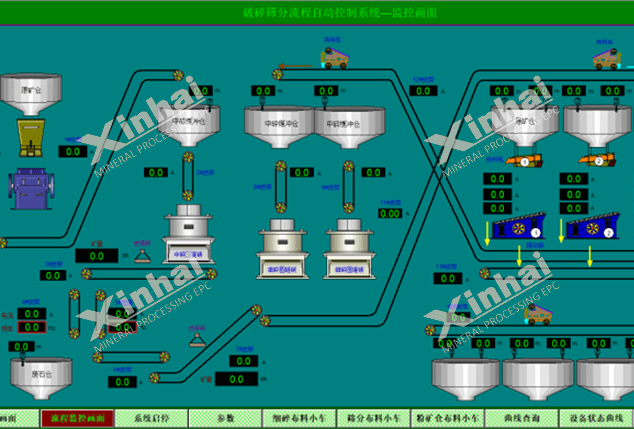

(Computer Monitoring System)

The main functions of the upper computer monitoring system include registration according to different levels of operators, system engineers and managers;

Site contact and operation mode (linkage/single action) selection before start-up;

Process flow screen display, equipment status description and dynamic display of process parameters;

Equipment start and stop control function (soft manual single start/stop function and full line linkage start/stop function);

Process parameter setting and adjustment and online adjustment of loop control parameters;

Process parameter trend curve (real-time trend and historical trend) display and printing function;

Historical data collection and automatic archiving and storage function;

Event recording (operator operation records process parameters or equipment status and control mode changes, alarm generation, confirmation, etc.) function;

Data statistical analysis function;

Alarm display (in chronological order, according to priority level, according to the area where the fault point is located, etc.) function;

Real-time report/event information printing function;

Production reports can be generated and printed automatically or at any time;

Monitoring system hardware fault diagnosis and status monitoring function;

Online configuration and maintenance of the system, etc.

02 Optimized Control System

BackThe optimization control system is divided into four subsystems, namely, vertical furnace roasting optimization control subsystem, weak magnetic ball mill optimization control subsystem, strong magnetic ball mill optimization control subsystem and strong magnetic machine optimization control subsystem.

1. The control of the roasting and grinding process of the shaft furnace is the key to the control of the mineral processing production process.

The roasting process is to reduce the weak magnetic hematite (Fe2O3) into strong magnetic magnetite (Fe3O4), so that it can be sorted on the magnetic separator with low magnetic field strength for sorting strong magnetic minerals to achieve the purpose of improving the metal recovery and concentrate grade.

The roasting process is roughly divided into three stages: heating, reduction and cooling. The input has the air volume, heating gas volume and reduction gas volume; the output has the combustion chamber temperature, heating zone temperature and reduction zone temperature.

The process mechanism is complex, such as the entry and exit of ore, heat transfer and chemical reaction, and there are many uncertainties, such as changes in the characteristics of ore and fluctuations in the composition of heating gas, and the recovery rate of the magnetic separation tube, which is an indicator of the excellence of the roasting operation, cannot be continuously measured online.

The grinding process has large hysteresis, strong coupling of multiple variables, severe nonlinearity, and the grinding particle size cannot be measured continuously online accurately. Therefore, the roasting process and the grinding process are difficult to use an optimal control method based on an accurate mathematical model.

To solve this problem, intelligent optimal control technology is used to achieve optimal control of the beneficiation process through a two-layer structure: loop control layer and loop optimization setting layer.

2. The comprehensive production indicators of the beneficiation process are metal recovery, concentrate grade and concentrate yield.

The optimization control system generates the optimized set values of magnetic separation tube recovery rate and grinding size through the key process parameters setting model based on case inference, and makes the temperature, pressure, flow rate, feed volume and slurry concentration of the beneficiation production process follow the optimized set values stably through loop feedback control.

The input and output quantities of the beneficiation process are used to generate the predicted values of tube recovery, mill load and slurry size by means of the prediction models of tube recovery, mill load and slurry size, and compare them with the optimized values of tube recovery, mill load and slurry size, and the resulting errors are corrected by feedforward compensation. The error is corrected by feedforward compensation to the circuit optimization setpoint, and the recovery rate and pulp size values from sampling are compared with the optimized values of the recovery rate and pulp size to correct the circuit setpoint and optimize the beneficiation process.

03To Wrap Up

BackThe above is the application of automation in iron ore processing plant. If you need to know more about the automation of ore dressing, or need to automate the construction and transformation of ore dressing plants, please leave a message or consult online customer service.

+86 182 3440 3483

+86 182 3440 3483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now