Cobalt Extraction Process: Complete Guide

Sheena

Sheena

Nov 25, 2025

Nov 25, 2025

710

710

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Cobalt-Extraction-Process

This makes efficient mineral processing and beneficiation crucial to maximize recovery and ensure commercial feasibility. This article provides a full overview of gravity separation, flotation, magnetic separation, and modern combined beneficiation processes.

01Understanding Cobalt Ores

BackCobalt rarely occurs as a standalone mineral resource. Instead, it is commonly found in the following deposit types:

1 Cobalt Sulfide Ores

These ores often contain:

Chalcopyrite

Pentlandite

Pyrrhotite

Pyrite

Because cobalt minerals are usually fine-grained and embedded within copper or nickel sulfides, flotation is the primary extraction method.

2 Cobalt Oxide Ores

Formed by weathering or oxidation of sulfide ores, containing:

Limonite

Goethite

Hematite

Mixed lateritic materials

These may require gravity separation, magnetic separation, or flotation after activation.

3 Copper–Cobalt (Cu–Co) Ores

Most famous in Central Africa’s Copperbelt, these ores typically combine:

Sulfides

Oxides

Carbonates

Mixed transitional zones

A combined process flow is required to treat such complex ores efficiently.

Understanding ore type is essential because it dictates:

Grinding fineness

Beneficiation technology

Equipment configuration

Expected recovery rate

02Major Cobalt Extraction Processes

Back1 Gravity Separation

When Gravity Separation Is Applicable

Gravity separation works best when cobalt minerals are:

Coarse-grained

Have a significantly higher density than gangue

Partially liberated

Suitable minerals include cobaltite and skutterudite in certain deposits.

Key Equipment for Gravity Separation

Jig Separators

High throughput

Good for coarse cobalt minerals

Shaking Tables

Excellent for fine gravity processing

Produces high-grade concentrates

Spiral Chutes

Low energy consumption

Ideal for pre-concentration in oxide ores

2 Flotation Process (Most Widely Used for Cobalt)

Flotation is the primary method for extracting cobalt from sulfide ores and many Cu–Co mixed ores. It allows selective separation using differences in mineral surface properties

Flotation Equipment

SF / BF Flotation Cells: High aeration and mixing capacity

XCF / KYF Flotation Cells: Suitable for large-scale plants, low power consumption

Flotation Columns: Produce high-grade concentrates, fewer cleaning stages

Benefits

High recovery efficiencies

Flexible adjustment through reagent control

Effective for complex or fine-grained ores

3 Magnetic Separation

Magnetic separation is often overlooked, but it plays a crucial role in many cobalt processing flows, especially in removing iron-rich gangue.

Magnetic Separation Equipment

Wet High-Intensity Magnetic Separators (WHIMS)

Capture weakly magnetic particles

Suitable for fine cobalt ore preparation

Dry Drum Magnetic Separators

Used for coarse gangue removal

Low energy requirement

03Combined Cobalt Beneficiation Processes

BackDue to the complexity of cobalt ores, combined flowsheets are now the industry standard.

1 Gravity + Flotation

This hybrid method is ideal for:

Mixed sulfide–oxide ores

Ores with both coarse and fine cobalt minerals

Flow Example

Gravity separation removes coarse waste and enriches cobalt.

Flotation upgrades fine cobalt minerals to high-grade concentrate.

2 Magnetic Separation + Flotation

Used for:

Iron-rich cobalt ores

Ores containing pyrrhotite or magnetite

Flow Example

Magnetic separation removes magnetic impurities.

Flotation produces high-grade cobalt concentrate.

This improves metallurgical performance dramatically.

3 Gravity + Magnetic + Flotation

A full combination process is essential for:

African copper–cobalt ore fields

Weathered or mixed mineral zones

Polymetallic cobalt ores

Why It Works

Each method targets a different mineral group:

Gravity → coarse cobalt minerals

Magnetic → iron-bearing gangue

Flotation → fine cobalt-bearing sulfides/oxides

.jpg)

04Cobalt Processing Plant (Complete Flow Design)

BackA professionally designed cobalt plant typically includes:

4.1 Primary Crushing

Jaw crusher

Cone crusher

Ensures consistent feed size.

4.2 Grinding & Classification

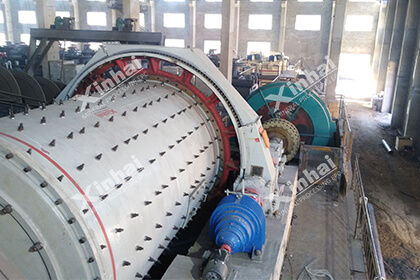

Ball mill / rod mill

Spiral classifier / hydrocyclone

Controls liberation and particle size distribution.

4.3 Pre-Concentration

Jig machine

Spiral chute

Magnetic separator

Reduces capacity pressure on the main flotation circuit.

4.4 Flotation Circuit

Roughing

Scavenging

Multi-stage cleaning

Utilizing flotation cells tailored to the ore type.

4.5 Concentrate Dewatering

Thickener

Filter press

Produces market-ready cobalt concentrate.

05Conclusion: The Future of Cobalt Extraction

BackAs demand for cobalt grows—driven by electric vehicles, renewable energy storage, and advanced manufacturing—the importance of efficient beneficiation will only increase. Modern cobalt extraction relies on a combination of gravity separation, magnetic separation, and flotation, supported by advanced equipment and integrated plant design.

For mining companies, EPC providers, and investors, choosing the right equipment supplier is essential. A partner that offers complete cobalt processing solutions—from ore testing and process design to equipment manufacturing and installation—can significantly improve both recovery rate and overall project success.

+86 182 3440 3483

+86 182 3440 3483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now