Recycling Lithium from Lepidolite: 4 Methods You Need to Know!

Miya

Miya

Apr 19, 2023

Apr 19, 2023

1415

1415

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

(Zimbabwe Lithium Ore Processing Plant)

Lepidolite is one of the important sources of lithium ore and is mainly produced from pegmatite-type lithium deposits. Lepidolite is a layered aluminosilicate mineral with a dense mineral structure and low reactivity, making it difficult to react with acids and bases under normal temperature and pressure. So, lithium extraction from lepidolite is relatively difficult. The methods for recovering lithium from lepidolite mainly include flotation recovery, acid leaching recovery, alkaline leaching recovery, and salt roasting recovery.

In this article, we will introduce these four methods for recovering lithium from lepidolite. Let's dive in now!

01Flotation Extraction of Lithium from Lepidolite

BackLepidolite ores are mostly of the fine-grained embedded type, and lepidolite is mainly intergrown with vein minerals such as quartz and feldspar. Flotation is the main method used to recover fine-grained lepidolite. In the flotation recovery of lepidolite, the formulation of reagents is very important. Under acidic conditions, amine collectors are used to float lepidolite, while under alkaline conditions, fatty acid collectors or combination collectors are used to float lepidolite. In addition, the use of anion-cation combination collectors can effectively improve the grade and recovery rate of lepidolite concentrates through the synergistic effect of reagents. The project we done in Zimbabwe is using flotation process to extract lithium.

(Various Kind of Flotation Reagents)

02Acid Extraction of Lithium from Lepidolite

BackAcid leaching is commonly used in the extraction of lithium from lepidolite, and its principle is that hydrogen ions diffuse from the solution to the original silica film layer of lepidolite, causing lepidolite to decompose into soluble sulfate salts. Depending on the treatment method, acid leaching can be divided into acid roasting, concentrated sulfuric acid pretreatment at room temperature, and mixed acid treatment. According to the type of acid used, it can be divided into sulfuric acid leaching and hydrofluoric acid leaching. Sulfuric acid leaching is the most widely used method, which involves roasting lepidolite with concentrated sulfuric acid at an appropriate temperature, followed by water leaching to obtain lithium sulfate solution. The valuable metals rubidium and cesium associated with lepidolite are converted into soluble salts during the acid treatment. The process of using hydrofluoric acid is similar to that of sulfuric acid, but the leaching temperature is lower, the leaching time is shorter, and the energy consumption is lower, providing favorable conditions for subsequent impurity removal. Based on this, using a mixed acid of hydrofluoric acid and sulfuric acid for leaching can obtain a higher leaching rate while reducing acid consumption.

03Alkaline Extraction of Lithium from Lepidolite

BackThe main method of alkaline extraction of lepidolite is limestone roasting. The basic principle is to use alkali to dissolve SiO2 in the solution. In alkali or gypsum, the silicate is converted into soluble lithium aluminate by heating, so that the mineral reacts with the mixture of limestone or hydroxide to obtain hydrogen lithium oxide or lithium carbonate.

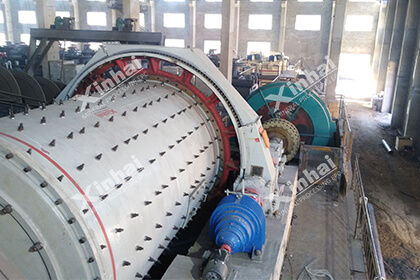

The lepidolite concentrate and limestone are mixed in a certain proportion for ball milling, and after mixing, the clinker is roasted at a high temperature of 800-900°C, and the clinker is then subjected to water quenching, fine grinding, leaching, filtration or centrifugal separation to obtain leachate and residue , the concentration of lithium in the immersion solution is low, the evaporation of concentrated and recovered lithium is large, the energy consumption is high, and the valuable metal elements in the ore are leached and enter the immersion solution with lithium.

04Salt Extraction of Lithium from Lepidolite

BackIn the salt method, the sulfate roasting method is the most widely used lithium extraction method. After the lepidolite is calcined at a high temperature, the structure becomes loose, and an ion exchange reaction occurs, that is, the metal ion in the added substance occupies the original lithium ion structure position, making it from the insoluble The method of separating from the aluminosilicate to form soluble sulfate can be divided into sulfate roasting method, chlorination roasting method, sulfide roasting method, etc.

Sulfate roasting method: The sulfate roasting method exchanges the cations in the sulfate with lithium ions, the lithium ions are replaced, and the lithium sulfate solution is obtained by leaching. The sulfate method has less impurity content, higher leaching rate, better comprehensive metal recovery effect and simple process, and has been widely used in the industrial production of lepidolite lithium extraction. However, the sulfate method also needs to be completed after high-temperature calcination. During the high-temperature calcination process, fluorine and sulfide-containing waste gas will volatilize, and the environmental pollution is relatively serious. The minerals are easy to stick together during the calcination process, which reduces the calcination efficiency. The product is easily contaminated by potassium.

Chlorination roasting method: The chlorination roasting method is to convert lithium and other valuable metals in lepidolite into soluble chlorides, and obtain a lithium-containing solution after leaching to realize the extraction of lithium and alkali metals. The chlorination roasting method can effectively shorten the time, produce a small amount of silicon-aluminum slag and is easy to use, but the gasification of chlorides will pollute the environment, and the use of chlorine has high operational risks, and has higher requirements for equipment anti-corrosion, resulting in production Increased costs.

Sulfide roasting method: Sulfide roasting is the use of sulfides (such as Na2S and FeS) to extract lithium effectively by roasting or grinding and leaching with water. The iron sulfide reagent used in this process is cheap, low baking temperature, environmentally friendly, low impurity content and high leaching rate, but the grinding time in the experiment is long, and sulfur-containing compounds may volatilize into the atmosphere and cause air pollution.

05To Wrap Up

BackThe above are four methods for lithium extraction from lithium mica. In actual production, the recovery of lithium needs to consider various factors. For the production of beneficiation plants, it is very important to understand the composition and properties of minerals. Based on this, mineral processing test is to some extent necessary, which can effectively reduce investment loss.

+86 182 3440 3483

+86 182 3440 3483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now