The Complete Guide of Jig for Mineral Processing

Essow

Essow

Aug 22, 2022

Aug 22, 2022

12186

12186

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

The Jig is the gravity separation machine for separating the ore particles according to density by the combined action of mechanical shaking and water flushing.

Jig beneficiation is one of the most effective gravity separation methods for processing coarse ores with large density difference.

When the separating medium is water, it is called hydraulic jigging; if the medium is air, it is called air jigging; if the medium is dense medium, it is called dense medium jigging.

Mineral processing plants use mostly hydraulic jigging processes.

01 How Does A Jig Work?

BackThe mineral particles form a bed layer on the jig. Due to the forced vibration of the transmission mechanism, periodic vertical alternating water flow is formed in the jig box. Under the action of rising water, the bed layer is loose, and the ore particles are gradually stratified according to the density, particle size and shape.

During the action stage of the descending water flow, the bed layer is gradually compacted, and the ore particles continue to move and stratify until most of the ore particles sink to the screen plate and stop moving. At this time, only very fine and heavy ore particles can drill to the bottom layer (ie, drilling gap) with the descending water flow through the bed layer gap.

In order to control the degree of drilling gap and ensure the quality of concentrate, artificial beds are often laid and a certain amount of under screen water is added. When the descending water flow ends, and the stratification ends.

During this process, the water flow completes a cycle called a jigging cycle. The curve representing the relationship between water flow velocity and time is called the jigging cycle curve.

After repeating this for many times, the stratification according to the density is gradually perfected. The result is that the ore particles with small density are concentrated in the upper layer, and the ore particles with high density are concentrated in the bottom layer.

The layered heavy products are discharged from the lower part of the box by the ore discharge device (suitable for coarse-grained materials) or through the artificial bed layer, through the screen plate (suitable for fine-grained materials), and become concentrates. The light products are discharged from the tail end of the machine with the horizontal overflow and become tailings.

When using jig beneficiation, the minerals are mainly stratified by density, but the particle size and shape will affect the accuracy of stratification by density.

(Diaphrgam Jig)

02 What Are the Minerals Suitable for Jig?

BackJig beneficiation is widely used in the beneficiation of tungsten, tin, iron, manganese, coal and other ores. In China, about two-thirds of the tungsten ore is processed by jigging, and jig has always been the dominant for the processing of coal. At present, some weak magnetic iron ore processing plants also use jigs as the main equipment.

We have an article about how to extract tungsten ore, click the link to check it.

Its processing size range for metal ore is 30~0.074 mm, sometimes up to 50 mm; for coal is 100~0.5 mm, sometimes up to 200 mm.

Jig beneficiation technology is simple, easy to operate, large in processing capacity, and good in effect. It is a promising method of gravity separation.

03 What Are the Common Types of Jig?

BackThere are 3 commonly used Jig machines, which are diaphragm jig, air pulsating jig and moving jig.

#1 Diaphragm Jig

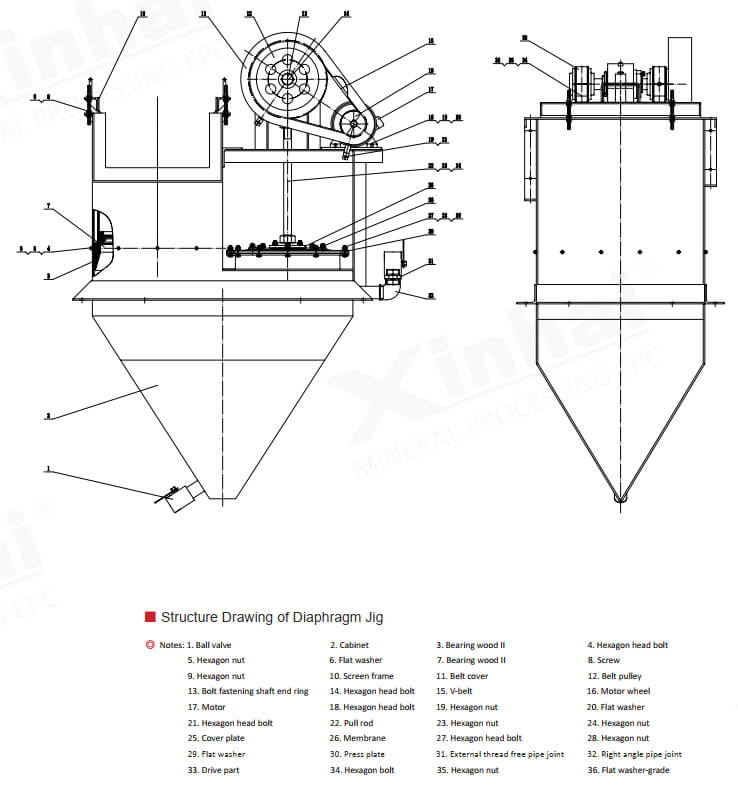

Diaphragm jig is a type of jigging machine that is widely used in gravity separation plants, whose working principle is to drive the diaphragm by eccentric connecting rod, cam lever or hydraulic device causing reciprocating motion. Based on the diaphragm installation position, diaphragm jigs can be divided into top-moving (side-moving) diaphragm jigs, down-moving conical diaphragm jigs, lateral diaphragm jigs, and so on.

(Structure of Diaphragm Jig)

#2 Air Pulsating jig

The air pulsating jig is also called a pneumatic jigger, which is separating minerals by air compression. According to different air chamber positions, air pulsating jigs can be divided into screen side air chamber (side drum type) jigs and under screen air chamber jigs. The air pulsation jig is mainly used in coal processing.

#3 Moving Jig

Moving screen jigs can be divided into mechanical moving jigger and manual moving jigger by the various drive systems. Manual moving screen jigs have basically been eliminated, while mechanical moving jiggers drive the screen plate to reciprocate through hydraulic or mechanical force, which can sort the material on the screen plate. This moving jigger is mainly used for large-scale coal beneficiation plant or coal processing plants in cold and water-deficient areas.

04 How to Reach the Best Effect of Jigging process?

BackThere are many factors affecting the jigging process, mainly including material properties, mechanical structure, and operating factors. For a certain material and jig, determining a reasonable operating system is the guarantee of obtaining a good separation effect. Experience has shown that stroke, number of strokes, adding water under the screen regime and bed properties are the most important operating factors.

(Jig Machine)

#1 Stroke (s) and Number of Strokes (n)

The stroke and the number of strokes have a great influence on the loosing and layering of the bed. Different stroke times will result in different water flow characteristics and loose time and space conditions.

Increasing the speed of water flow can increase the thrust of the water flow; increasing the acceleration of the water flow can increase the thrust of the water flow acceleration, thus causing different effects on the ore particles.

If the water flow rate is too small, the looseness of the bed is too small; if the water flow acceleration is too large, or even exceeds the acceleration of gravity, the bed layer will be lifted as a whole and cannot be loosened well.

A larger stroke can make the bed lift higher and obtain a higher loose space; a larger stroke times can keep the bed loose for a shorter time, but speed up the layering speed.

Therefore, suitable loosening and stratification is the result of the combination of suitable strokes and stroke times.

The stroke and the number of strokes should be determined through experiments according to the nature of the material, the separation operation, the operating conditions and the different requirements for the product.

For materials with high density, coarse particle size or large bed thickness, large processing capacity, and high concentrate rate, larger strokes and smaller stroke times are required.

When the water under the screen is small, a larger stroke should be used.

Generally, two coordination systems of large stroke and small stroke times or small stroke and large stroke times should be adopted.

For coarse-grained materials, large strokes and small stroke times should be used; for fine-grained materials, small strokes and large stroke times should be used.

#2 Add Water Under the Screen

The function of supplementary water under the screen is not only to supplement the water consumed by the tailings discharge, but also to adjust the bed looseness and weaken the strong suction effect of the descending water flow, so as to control the quantity and quality of the concentrate discharged under the screen.

The quantity of the under screen water is mainly adjusted according to the looseness of the bed and the yield and quality requirements of the concentrate.

When the material density is large, the processing capacity is large, and the bed is thick, increasing the amount of supplementary water under the screen can increase the looseness of the bed.

For wide-grade materials, it is not only required to have an appropriate degree of looseness, but also hope that the fine and heavy ore particles will not be lost to the tailings due to the excessive lifting effect of the upward flow. At this time, a small amount of supplementary water under the screen should be controlled.

For operations that require high concentrate grade (such as fine-grain jigging before classification), the amount of under screen water can be more; if the main purpose is to reduce the grade of tailings (such as jigging after grading), the amount of under screen water should be small.

The effect of supplementary water under the screen on materials of different properties is different.

For coarse-grained materials, it is often futile to try to greatly change the looseness of the bed by increasing the supplementary water under the screen, and at the same time, it will consume a lot of water, which is very uneconomical.

But for medium and fine-grained materials, it is very sensitive and effective to adjust the supplementary water under the screen.

When jigging, the amount of water added under the screen is required to be sufficient, and the amount of water should be kept constant. For general metal ore beneficiation, the water volume is 5~10 meters per ton of ore, and the water pressure is required to be greater than 2 kg/cm.

#3 Bed Properties and Composition

The thickness of the bed mainly affects the degree of loosening and the speed of ore particle stratification.

For ore with a large difference in density between useful minerals and gangue, in order to speed up the stratification and improve the production capacity, a thin bed should be used; when the quality requirement of the concentrate is high, a thick bed should be used.

The thickness of the bed is controlled by the height of the tail plate of the jig, which is usually 100~200 mm.

When separating fine-grained ore less than 2 mm, the through screen ore discharge method is adopted. At this time, an artificial bed must be laid on the screen plate to adjust and control the quantity and quality of the concentrate. The composition of the artificial bed (the thickness of the artificial bed and the particle size and density of the bed stone) has a great influence on the quantity and quality of the concentrate.

When the bed stone is coarse in particle size, low in density, small in artificial bed thickness and large in pores, fine particles can easily penetrate the artificial bed. At this time, the concentrate recovery rate is high, but the grade is low; on the contrary, the recovery rate is low and the concentrate grade is high. .

The density of the artificial bed should be equal to or slightly lower than that of the dense minerals. The particle size of the artificial bed is generally more than three times the maximum particle size of the concentrate under the screen. The thickness of the artificial bed is not less than half of the height of the jigging chamber, generally 10-70 mm. The particle size ratio of the bed should be as appropriate as possible, and the shape should be as uniform and smooth as possible.

It should be pointed out that the various factors affecting the jigging process are not isolated from each other and must be analyzed in detail. The appropriate operating system is best determined by experiment.

+86 182 3440 3483

+86 182 3440 3483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now