New Energy Minerals: Powering the Future with Sustainable Resources

Essow

Essow

May 28, 2024

May 28, 2024

1926

1926

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

In a world transitioning towards cleaner and more sustainable energy sources, new energy minerals have emerged as vital components in driving this transformation. These minerals, often associated with renewable energy technologies and energy storage systems, play a crucial role in powering the future and reducing our reliance on traditional fossil fuels. Let's delve into the realm of new energy minerals and explore their significance in shaping a sustainable energy landscape.

01 Brief Introduction for New Energy Minerals

Back1. Lithium

Lithium, often referred to as the "white gold," is a key component in lithium-ion batteries, widely used in electric vehicles (EVs) and energy storage systems. Its high energy density and excellent charge-discharge efficiency make it an ideal choice for portable and stationary power applications. As the demand for EVs and renewable energy storage expands, lithium production and exploration have gained significant attention.

(Lithium Ore)

2. Cobalt

Cobalt is an essential mineral in lithium-ion batteries, particularly for their cathode composition. It enhances battery stability and performance. However, concerns about ethical and sustainable cobalt sourcing have led to increased efforts to develop alternative cathode chemistries with reduced or no cobalt content. Nonetheless, cobalt remains a valuable resource in the transition to clean energy.

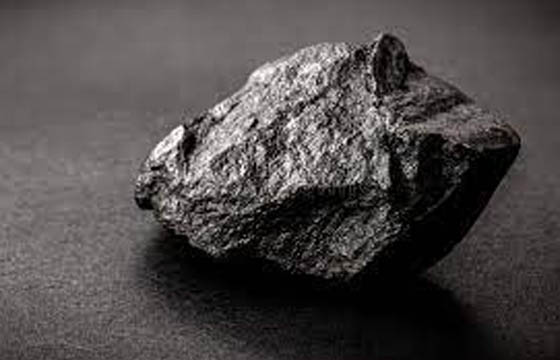

3. Graphite

Graphite is a critical component in lithium-ion batteries, serving as the anode material. It enables efficient energy storage and release during charge and discharge cycles. The growing demand for EVs and energy storage systems has fueled the graphite market, necessitating increased graphite production and refining capabilities.

(Graphite Ore)

4. Rare Earth Elements (REEs)

REEs are a group of seventeen elements with unique magnetic, optical, and catalytic properties. They are utilized in various clean energy technologies, including wind turbines, electric motors, and energy-efficient lighting. Neodymium, praseodymium, and dysprosium are particularly important in the production of high-performance magnets used in electric motors.

5. Nickel

Nickel is a versatile metal experiencing heightened demand due to its use in lithium-ion batteries. It offers multiple benefits, including increased energy density, enhanced stability, and improved performance. The adoption of nickel-rich battery chemistries aims to further enhance the energy storage capabilities of batteries, enabling longer-range EVs and more efficient renewable energy integration.

(Nickel Ore)

6. Vanadium

Vanadium is a key player in grid-scale energy storage systems. Vanadium redox flow batteries (VRFBs) utilize vanadium ions in an electrolyte solution to store and release energy. VRFBs offer long cycle life, scalability, and the ability to decouple energy capacity from power capacity, making them suitable for large-scale energy storage applications.

Here's an overview of the beneficiation methods commonly used for new energy minerals:

02 Beneficiation Methods for New Energy Minerals

Back1. Lithium

Lithium beneficiation typically involves a combination of physical and chemical processes. The primary method is called "roasting," where lithium-bearing minerals, such as spodumene or lepidolite, are heated at high temperatures to convert the lithium into a soluble form. The resulting concentrate undergoes further processing, including acid or alkaline leaching, precipitation, and purification steps to obtain high-purity lithium compounds suitable for battery production.

We have an article about lithium processing solutions, please click the link to check. Lithium Mineral Processing Solutions: Optimizing Resource Recovery

2. Cobalt

Cobalt beneficiation methods depend on the specific cobalt-bearing minerals present in the ore. Flotation is commonly used to separate cobalt minerals from other non-valuable minerals. The ore is ground and mixed with water, then chemicals known as collectors are added to selectively attach to the cobalt minerals, allowing them to float while the gangue minerals sink. The cobalt concentrate undergoes further processing, including smelting or hydrometallurgical techniques, to produce cobalt metal or cobalt compounds.

We have an article about cobalt processing solutions, please click the link to check. A Comprehensive Guide to Cobalt Processing Equipment.

3. Graphite

Graphite beneficiation usually involves a combination of crushing, grinding, flotation, and thermal or chemical treatment methods. The ore is typically crushed and ground to liberate the graphite flakes from the gangue minerals. Flotation is commonly employed to separate graphite from other minerals. Chemical reagents known as collectors are added to the flotation process to selectively attach to the graphite particles, allowing them to float while the gangue minerals are discarded as tailings. Thermal treatment, such as high-temperature purification or graphitization, may be applied to improve the graphite's quality and crystallinity.

We have an article about graphite processing solutions, please click the link to check. A Comprehensive Guide to Graphite Processing Equipment

4. Rare Earth Elements (REEs)

Beneficiation of rare earth elements involves a series of physical and chemical processes depending on the specific mineralogy of the ore. Common techniques include flotation, magnetic separation, and gravity separation. Flotation is used to separate rare earth minerals from other minerals by utilizing different collectors and depressants. Magnetic separation exploits the magnetic properties of certain rare earth minerals, while gravity separation utilizes the differences in density between minerals. Additional hydrometallurgical processes may be employed to further refine and separate individual rare earth elements.

5. Nickel

Nickel beneficiation methods vary depending on the nature of the ore deposit. For sulfide ores, froth flotation is commonly used. The crushed and ground ore is mixed with water and chemicals, including collectors and frothers, to selectively float the nickel-bearing sulfide minerals, while the gangue minerals sink. For laterite ores, which are oxide or clay-rich, various techniques such as leaching, precipitation, and solvent extraction may be employed to separate and refine the nickel.

We have an article about nickel processing solutions, please click the link to check. The Comprehensive Guide to Nickel Processing

6. Vanadium

Vanadium beneficiation is typically accomplished through physical and chemical processes. The primary method for extracting vanadium is known as "salt roasting," where the vanadium-bearing ore is mixed with salt and heated. This process converts vanadium compounds into water-soluble forms. The resulting solution is then subjected to further chemical processing, including solvent extraction, precipitation, and refining steps to obtain vanadium compounds suitable for various applications.

These beneficiation methods are continuously evolving and may be adjusted based on the specific mineral deposits, ore characteristics, and desired product specifications. The goal is to maximize the recovery of valuable minerals while minimizing the environmental impact and ensuring the production of high-quality materials for new energy applications.

The beneficiation methods for new energy minerals can have various environmental impacts, which need to be carefully managed and mitigated. Here are some of the common environmental concerns associated with these processes:

03 Environmental Impacts Associated with the Beneficiation Methods for New Energy Minerals

Back1. Energy Consumption and Greenhouse Gas Emissions

The beneficiation of minerals often involves energy-intensive processes, such as crushing, grinding, and thermal treatment. The energy requirements contribute to carbon emissions and can have a significant environmental footprint. It is important to implement energy-efficient practices and explore renewable energy sources to minimize greenhouse gas emissions.

2. Water Usage and Contamination

Beneficiation processes require substantial amounts of water for grinding, flotation, and chemical treatment. Water scarcity can be a concern in certain regions, and the withdrawal and discharge of large volumes of water can impact local ecosystems. Additionally, the chemicals used in flotation and leaching processes can contaminate water sources if not properly managed, leading to adverse effects on aquatic life and water quality.

3. Waste Generation and Tailings

Beneficiation processes generate substantial amounts of waste materials, including gangue minerals, tailings, and processing residues. These wastes can have physical, chemical, and ecological impacts. Improper disposal or management of tailings can result in the release of contaminants into the environment, potentially polluting soil, water bodies, and affecting surrounding ecosystems.

4. Air Pollution

Certain beneficiation processes, such as roasting or thermal treatment, can release air pollutants, including particulate matter, sulfur dioxide (SO2), nitrogen oxides (NOx), and volatile organic compounds (VOCs). These emissions can contribute to air pollution, respiratory health issues, and the formation of smog if not properly controlled through emission control technologies.

5. Habitat Disruption and Biodiversity Loss

Mining activities associated with the extraction of these minerals can lead to habitat disruption, soil erosion, and fragmentation of ecosystems. The clearing of vegetation, excavation, and infrastructure development can have negative impacts on biodiversity, including the loss of plant and animal species and disruption of ecological processes.

6. Acid Mine Drainage

In certain cases, the exposure of sulfide minerals during the beneficiation process can lead to the formation of acid mine drainage (AMD). AMD occurs when sulfide minerals react with air and water, generating acidic conditions and releasing toxic metals into nearby water bodies. This can have severe ecological consequences, including the contamination of aquatic ecosystems and the degradation of water quality.

To mitigate these environmental impacts, it is essential to implement sustainable practices throughout the mining and beneficiation lifecycle. This includes adopting cleaner and more efficient technologies, implementing water management strategies, utilizing effective waste management and tailings disposal methods, and implementing proper air emission control systems. Furthermore, adherence to strict environmental regulations, environmental monitoring, and ongoing research and development efforts are necessary to minimize the environmental footprint of these processes and ensure responsible mineral extraction and beneficiation.

04 Key Strategies and Solutions to Mitigate These Problems

BackAddressing the environmental challenges associated with the beneficiation methods for new energy minerals requires a multi-faceted approach involving various stakeholders. Here are some key strategies and solutions to mitigate these problems:

1. Adoption of Clean Technologies

Promote the use of cleaner and more energy-efficient technologies throughout the beneficiation process. This includes implementing advanced grinding, flotation, and separation techniques that minimize energy consumption and reduce greenhouse gas emissions. Explore the use of renewable energy sources to power the beneficiation operations, thereby reducing reliance on fossil fuels.

2. Water Management and Conservation

Implement water management strategies to optimize water usage and minimize impacts on local water sources. This includes recycling and reusing water within the beneficiation process, implementing water treatment and filtration systems to minimize contamination, and exploring waterless beneficiation techniques where feasible. Implement responsible water management practices to reduce the strain on local water resources.

3. Tailings Management and Waste Minimization

Develop and implement comprehensive tailings management plans to minimize the environmental impact of waste materials. This involves proper design and engineering of tailings storage facilities, adopting technologies for the dewatering and stabilization of tailings, and implementing best practices for the safe disposal and reclamation of tailings areas. Promote waste minimization strategies, such as optimizing resource recovery from waste streams and exploring opportunities for recycling and reuse.

4. Emission Control and Air Quality Management

Employ effective emission control technologies to minimize air pollution associated with beneficiation processes. This includes the use of dust suppression systems, particulate filters, and scrubbers to capture and treat emissions. Implement comprehensive air quality monitoring programs to ensure compliance with environmental regulations and to identify and address potential impacts.

5. Biodiversity Conservation and Land Reclamation

Develop and implement biodiversity management plans that address habitat disruption and species conservation. This includes conducting thorough environmental impact assessments, implementing measures to minimize habitat disturbance, and promoting land reclamation and restoration activities. Engage in sustainable land-use practices and consider the establishment of protected areas or conservation initiatives to preserve biodiversity.

6. Responsible Mining Practices and Compliance

Adhere to stringent environmental regulations and engage in responsible mining practices. This includes conducting thorough environmental impact assessments prior to commencing operations, implementing robust environmental management systems, and regularly monitoring and reporting environmental performance. Foster transparency and engage with local communities and stakeholders to address concerns and ensure sustainable mining practices.

7. Research and Development

Invest in research and development initiatives to advance beneficiation technologies and processes with reduced environmental impact. This includes exploring innovative methods for mineral extraction and beneficiation, developing greener reagents and chemicals, and investigating alternative approaches such as bioleaching or bio-beneficiation. Encourage collaboration between industry, academia, and government bodies to drive innovation and sustainable practices.

By implementing these strategies and solutions, the environmental impacts associated with the beneficiation of new energy minerals can be minimized, contributing to a more sustainable and responsible mining industry. Continuous improvement, technological innovation, and collaboration among stakeholders are essential to ensure the long-term environmental sustainability of these processes.

05Conclusion

BackNew energy minerals are revolutionizing the way we generate, store, and utilize energy. These minerals, including lithium, cobalt, graphite, rare earth elements, nickel, and vanadium, drive the development of renewable energy technologies and energy storage systems. As the world embraces a sustainable energy future, the responsible extraction, production, and recycling of these minerals become crucial. By harnessing the potential of new energy minerals, we can pave the way for a cleaner, more efficient, and sustainable energy landscape, reducing our carbon footprint and powering the future generations.

+86 182 3440 3483

+86 182 3440 3483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now