How to Extract Laterite Nickel Ore? 7 Processing Methods

Star

Star

May 31, 2022

May 31, 2022

3211

3211

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

The processing methods of laterite nickel ore is mainly divided into two types: pyrometallurgy process and hydrometallurgy process. According to the difference of nickel, cobalt content and ore type, and different working conditions, there are 7 kinds of methods to choose from. This article will introduce you to these 7 laterite nickel ore processes.

Pyrometallurgy mainly deals with metamorphic peridotite with 1.5%-3% Ni, 10%-40% Fe, 5%-35% MgO, and 1%-2% Cr2O3. The extraction of laterite nickel ore by pyrometallurgy includes: submerged arc furnace method, blast furnace method, blast furnace method, submerged arc furnace method and rotary kiln granulated iron method.

01 Rotary kiln drying and prereduction-electric furnace reduction smelting method

BackRotary kiln drying and pre-reduction-electric furnace reduction smelting is a classic process for processing laterite nickel ore. In the rotary kiln (800 ℃), the laterite nickel ore with about 30% water content will be dehydrated and pre-reduced. Then, treated material is transported to an electric furnace, and is reduced and smelted at a high temperature of 1600°C to produce ferronickel with a nickel content of >15%.

This method has high energy consumption and is suitable for processing laterite nickel ore with nickel > 2% and cobalt < 0.05%, and requires sufficient local power supply or material supply.

02 Sintering blast furnace vulcanization smelting method

BackSintering blast furnace vulcanization smelting is also a classic process. After laterite nickel ore, calcium oxide and SiO2 are fully mixed, it is sintered into a block at a high temperature of 1100 °C. Pyrite (20%) and coke (20%-30%) are added to the agglomerates, and they are smelted in a blast furnace at a temperature of 1350 °C to obtain a low nickel matte with a nickel content of 8%-15%.

The nickel recovery rate of this process is usually above 85%, and cobalt can also be recovered at the same time, which is suitable for treating laterite nickel ore with a Ni content of more than 1%.

03 Sintering - blast furnace reduction smelting method

BackThe laterite nickel ore is treated with an iron-making blast furnace of less than 500m³ to produce nickel pig iron containing 1.5%-5% nickel.

04 Rotary kiln direct reduction method to produce ferronickel powder

BackIn the production process of direct reduction of laterite nickel ore rotary kiln to produce ferronickel powder, the mixture after briquetting is fed from the kiln end of the rotary kiln. With the rotation of the kiln body, the material moves forward and interacts with the high temperature flue gas at the kiln head. A countercurrent is formed, followed by preheating, decomposition transition, high temperature reduction, condensation and other heat exchange reactions.

(Rotary kiln for laterite nickel ore process)

The above four processes belong to the pyrotechnics. The biggest disadvantage is that the energy consumption is high. At present, the laterite nickel ore that can be treated by the pyrotechnics has become less and less, and the future development direction will be mainly based on the hydrometallurgy method.

Hydrometallurgy can effectively recover valuable metals such as nickel, cobalt, and iron. And it has the advantage of low energy consumption. The extraction of laterite nickel ore by hydrometallurgy includes: reduction roasting - atmospheric pressure ammonia leaching process, high pressure acid leaching process and atmospheric pressure acid leaching process.

05 Reduction roasting-atmospheric pressure ammonia leaching process

BackThe reduction roasting-atmospheric pressure ammonia leaching process was first invented by Professor Caron, so it is also called the Caron process. The ammonia leaching process is to reduce nickel to metallic nickel through reduction roasting, and reduce most of the iron to ferric oxide (a small amount of iron oxide is reduced to metallic iron), then leaches metallic nickel with ammonia, and distills the ammonia leaching solution with a distillation tower. , to form a slurry of basic nickel carbonate and send it to a calcining kiln for drying and calcination. NiO is obtained after calcination, which can either be sold directly as a product or be further reduced to metallic nickel.

06 Pressurized acid leaching process

BackThe pressurized acid leaching method is to use dilute sulfuric acid to leach laterite nickel ore in an autoclave (240~265℃, 4-5MP), so that Ni, Co and H2S04 react to form soluble dibasic sulfate into the solution, while iron remains. in the slag. After the leaching pulp is washed in countercurrent with a washing thickener, hydrogen sulfide is introduced into the autoclave to precipitate nickel-cobalt sulfide, and finally, the nickel-cobalt sulfide is refined.

07 Atmospheric pressure acid leaching process

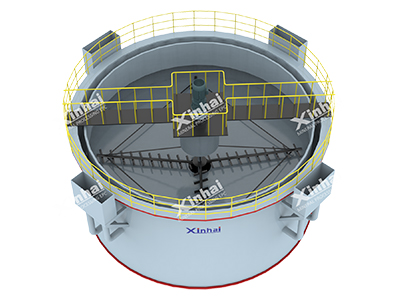

BackThe general process of treating laterite nickel ore by atmospheric acid leaching method is as follows: grinding laterite nickel ore to a certain fineness with a ball mill and mixing slurry with agitation tank. The ore pulp, sulfuric acid and washing liquid are reacted in a certain proportion under the condition of heating. After the leached nickel is dissolved in the solution, calcium carbonate is used for neutralization treatment and filtration. The obtained leaching liquid is subjected to nickel precipitation with a precipitant.

The acid granulation heap leaching process was studied on a low-grade laterite nickel ore with sulfuric acid under atmospheric pressure. The ore was crushed to<20mm, and N603 was used as the binder. 3809/L H2s04 cold solution was used as a wetting agent for granulation and 4-stage series column immersion. The nickel leaching rate can reach more than 85%. The atmospheric pressure leaching method has the advantages of simple process, low energy consumption and low investment cost, but it is difficult to separate the leaching liquid, and the nickel content in the leaching residue is still high.

08To Wrap up

BackThe above is an introduction to the 7 processing methods of laterite nickel ore. At present, the combined process of atmospheric pressure leaching and high pressure leaching is widely used to process laterite nickel ore. Mine owners can choose the appropriate treatment process according to the nature of the ore.

If you want to customize the laterite nickel ore extraction process, you can contact customer service or leave a message, and we will give you feedback as soon as possible.

+86 182 3440 3483

+86 182 3440 3483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now