Factors Affecting Gold Leaching Effects: A Comprehensive Overview

Laura

Laura

Jun 18, 2023

Jun 18, 2023

5028

5028

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

( Three million tpa gold ore heap leaching plant in Mongolia )

Gold leaching is the process of extracting gold from its ores using chemical reactions. It is a crucial step in the mining industry, as it allows the extraction of gold from low-grade ores that would otherwise be uneconomical to process. The process involves dissolving the gold in a solution containing a reagent, usually cyanide, which forms a complex with the gold. The complex is then separated from the ore and the gold is recovered from the solution.

Understanding the factors that affect gold leaching effects is critical to optimizing the process and improving the efficiency of gold extraction. In this comprehensive overview, we will explore the various factors that affect gold leaching effects, including pH, temperature, particle size, oxygen concentration, cyanide concentration, mineralogy, agitation, heap leaching optimization, impurities, and comparing leaching effects of different gold ores.

01 Factors Affecting Gold Leaching Effects

Back1. pH: impact and optimization

The pH of the solution plays a crucial role in the gold leaching process. The optimal pH for gold leaching is between 10 and 11, as this provides the best conditions for the cyanide to form a complex with the gold. If the pH is too low, the reaction will be slow, resulting in poor gold recovery. If the pH is too high, the cyanide will decompose, reducing the efficiency of the process.

( pH impact and optimization in gold leaching )

2. Temperature: effect on kinetics and efficiency

Temperature also affects the rate of the gold leaching process. Higher temperatures increase the rate of the reaction, resulting in faster gold recovery. However, high temperatures can also lead to the decomposition of the cyanide, reducing the efficiency of the process. The optimal temperature for gold leaching is between 20 and 25 degrees Celsius.

3. Particle size: distribution and effect on leaching

The particle size of the ore also affects the gold leaching process. Smaller particles have a larger surface area, which allows for faster and more efficient gold recovery. However, if the particles are too small, they can become too compact, reducing the permeability of the heap and reducing the efficiency of the process. The optimal particle size for gold leaching is between 0.5 and 2.0 mm.

( Particle size distribution and effect on leaching )

4. Oxygen concentration: role and optimization

Oxygen is required for the gold leaching process to occur. The oxygen reacts with the cyanide to form a complex with the gold, allowing it to be dissolved in the solution. The optimal oxygen concentration for gold leaching is between 8 and 10 ppm. If the oxygen concentration is too low, the reaction will be slow, resulting in poor gold recovery. If the oxygen concentration is too high, it can lead to the oxidation of the cyanide, reducing the efficiency of the process.

5. Cyanide concentration: impact on kinetics and efficiency

The cyanide concentration is also a critical factor in the gold leaching process. The optimal cyanide concentration for gold leaching is between 0.1 and 0.5 g/L. If the cyanide concentration is too low, the reaction will be slow, resulting in poor gold recovery. If the cyanide concentration is too high, it can lead to the formation of metal cyanide complexes, reducing the efficiency of the process.

6. Mineralogy: influence on leaching effects

The mineralogy of the ore can also affect the gold leaching process. Some minerals, such as pyrite and arsenopyrite, can consume large amounts of cyanide, reducing the efficiency of the process. Other minerals, such as quartz and feldspar, can interfere with the gold leaching process by adsorbing the cyanide, reducing the amount available for gold dissolution.

( Mineralogy influence on leaching effects )

7. Agitation: effect on kinetics and efficiency

Agitation is another critical factor in the gold leaching process. Agitation allows for the cyanide to be evenly distributed throughout the ore, increasing the efficiency of the process. The optimal agitation rate for gold leaching is between 400 and 600 rpm. If the agitation rate is too low, the reaction will be slow, resulting in poor gold recovery. If the agitation rate is too high, it can lead to the formation of air bubbles, reducing the efficiency of the process.

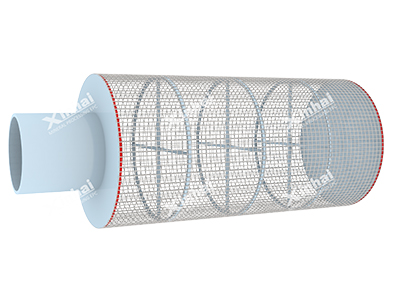

8. Heap leaching optimization for maximum gold extraction

Heap leaching is a common method used to extract gold from low-grade ores. Heap leaching involves stacking the ore on a pad and then irrigating it with a solution containing cyanide. The solution percolates through the ore, dissolving the gold, which is then recovered from the solution. Heap leaching can be optimized by controlling the pH, temperature, particle size, oxygen concentration, and cyanide concentration.

9. Impurities: effect on leaching efficiency

Impurities in the ore can also affect the gold leaching process. Some impurities, such as copper, can consume large amounts of cyanide, reducing the efficiency of the process. Other impurities, such as iron, can interfere with the gold leaching process by adsorbing the cyanide, reducing the amount available for gold dissolution.

10. Comparing leaching effects of different gold ores

Different gold ores have different characteristics that can affect the gold leaching process. By comparing the leaching effects of different gold ores, we can gain a better understanding of the factors that affect gold leaching effects and optimize the process for each specific ore.

02 Methods of Determining Gold Leaching Effects

Back1. Chemical analysis

Chemical analysis is the most common method used to determine the gold leaching effects. Chemical analysis involves analyzing the concentration of gold in the solution and the ore at various stages of the leaching process. This allows us to determine the efficiency of the process and optimize the conditions for maximum gold recovery.

( Chemical analysis in gold leaching )

2. Leaching tests

Leaching tests involve simulating the gold leaching process in a laboratory setting. This allows us to test different conditions and optimize the process without the need for large-scale testing.

( Leaching tests in gold leaching )

3. Kinetic modeling

Kinetic modeling involves using mathematical models to simulate the gold leaching process. This allows us to predict the efficiency of the process under different conditions and optimize the process for maximum gold recovery.

03Conclusion

BackIn conclusion, understanding the factors that affect gold leaching effects is critical to optimizing the process and improving the efficiency of gold extraction. By controlling the pH, temperature, particle size, oxygen concentration, cyanide concentration, mineralogy, agitation, heap leaching optimization, impurities, and comparing leaching effects of different gold ores, we can improve the efficiency of the process and maximize gold recovery. Chemical analysis, leaching tests, and kinetic modeling are all useful methods for determining gold leaching effects and optimizing the process. Future research should focus on developing new methods for improving gold leaching efficiency and reducing the environmental impact of the process.

Feel free to contact us and learn more about gold leaching! Or maybe you can leave a message and we will reply to you soon.

+86 182 3440 3483

+86 182 3440 3483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now