Core Steps of the CIL Process in Gold Processing

Sheena

Sheena

May 26, 2025

May 26, 2025

2411

2411

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

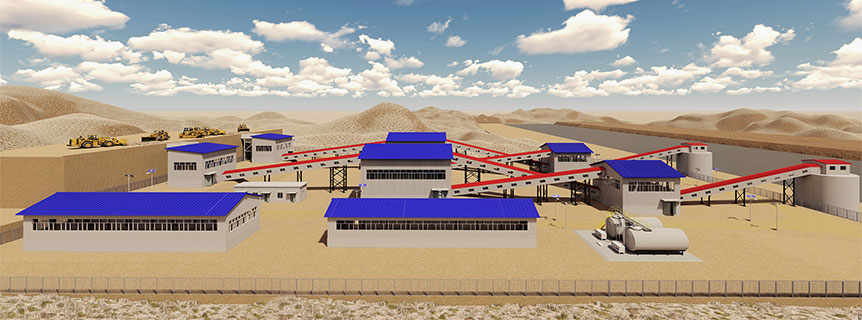

Mongolia-CIL-Concentrator

The Carbon-in-Leach (CIL) process is a highly efficient method used in the gold mining industry to extract gold from low-grade ores. It combines cyanidation and carbon adsorption into a single process, significantly improving gold recovery rates while reducing operational costs. This article outlines the core steps of the CIL process and explains how each stage contributes to successful gold extraction.

01Crushing and Grinding

BackThe first step in the CIL process involves crushing and grinding the ore into a fine powder. This increases the surface area, allowing better contact between the gold particles and the leaching agents. The ground material is then classified, and oversized particles are returned for further grinding.

02Slurry Preparation

BackNext, the ground ore is mixed with water and sometimes lime to create a slurry. This slurry is the medium in which chemical reactions will occur. Lime helps maintain a stable pH level, which is critical for the efficiency of the leaching process.

03Leaching and Adsorption

BackThis is the core stage of the CIL process. In this step, cyanide solution is added to the slurry, which dissolves the gold content in the ore. At the same time, activated carbon is introduced. The carbon adsorbs the dissolved gold ions, forming a gold-loaded carbon material. This simultaneous leaching and adsorption stage greatly enhances gold recovery.

04Carbon Separation

BackAfter the adsorption process, the carbon is separated from the slurry using screens. The loaded carbon, now containing the gold, is washed and moved to the next stage, while the barren slurry moves on for tailings treatment.

05Elution (Desorption)

BackIn the elution stage, the gold is stripped from the carbon using a hot caustic solution. This separates the gold into a concentrated solution, ready for further refining. The carbon is regenerated and recycled back into the process.

06Electrowinning and Smelting

BackThe gold-bearing solution undergoes electrowinning, where an electric current causes gold to deposit onto cathodes. The resulting gold sludge is then dried and smelted into gold bars, ready for market sale.

07Tailings Disposal

BackFinally, the leftover slurry—called tailings—is neutralized and safely disposed of or stored in tailings dams. Environmental management is a key component at this stage.

Why Choose the CIL Process?

The CIL process is widely used because of its:

High gold recovery rate

Reduced processing time

Cost efficiency

Simplified flow sheet

For gold processing plants, especially those working with low-grade ores, the CIL method remains a proven, scalable solution.

+86 182 3440 3483

+86 182 3440 3483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now