Manganese Extraction Process Explained

Sheena

Sheena

Jan 16, 2026

Jan 16, 2026

762

762

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Manganese-ore-to-be-processed

The extraction of manganese refers to the complete process of converting manganese-bearing ores into usable manganese products, such as manganese concentrate, ferromanganese alloys, or electrolytic manganese metal (EMM). This article provides a detailed overview of manganese ore types, extraction methods, processing flowsheets, and key equipment used in modern manganese processing plants.

01Types of Manganese Ores and Their Characteristics

BackUnderstanding ore characteristics is the foundation of an efficient manganese extraction process.

1. Oxide Manganese Ores

Examples: Pyrolusite (MnO₂), Psilomelane

Typically soft, brittle, and easy to beneficiate

Suitable for gravity separation, washing, and magnetic separation

2. Carbonate Manganese Ores

Example: Rhodochrosite (MnCO₃)

Lower density and more complex mineralogy

Often require flotation or combined beneficiation processes

3. Complex and Low-Grade Manganese Ores

Contain iron, phosphorus, silica, and clay

Require multi-stage processing and advanced separation technologies

02Overview of Manganese Extraction Methods

BackThe extraction method is selected based on ore grade, mineral composition, and final product requirements.

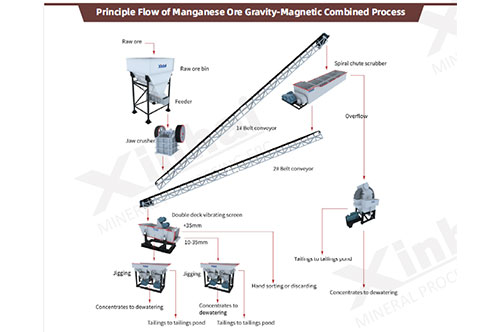

1. Physical Beneficiation (Mineral Processing)

Physical beneficiation is the most widely used method for manganese extraction at the mine site.

(1) Crushing and Grinding

Reduces ore size to liberate manganese minerals

Common equipment:

Jaw crushers

Cone crushers

Ball mills and rod mills

(2) Gravity Separation

Ideal for coarse-grained oxide manganese ores

Utilizes density differences between manganese minerals and gangue

Equipment:

Jig separators

Spiral chutes

Shaking tables

Advantages:

Low operating cost

No chemical reagents

Environmentally friendly

(3) Magnetic Separation

Used when manganese minerals are associated with iron minerals

High-intensity magnetic separators are commonly applied

(4) Flotation

Suitable for fine-grained and carbonate manganese ores

Requires specific reagents and precise control

Often combined with gravity separation to improve recovery

03Hydrometallurgical Extraction of Manganese

BackHydrometallurgy is mainly used for producing electrolytic manganese metal (EMM) and manganese chemicals.

1. Leaching

Acid leaching (sulfuric acid is most common)

Reductive leaching enhances Mn dissolution

Leaching agents:

Sulfur dioxide

Ferrous ions

Organic reducing agents

2. Purification and Solid–Liquid Separation

Removes impurities such as iron, cobalt, and nickel

Equipment:

Thickeners

Filter presses

3. Electrowinning

Produces high-purity manganese metal

Requires stable power supply and advanced cell design

Applications:

Battery-grade manganese

Specialty alloys

Chemical-grade manganese products

04Pyrometallurgical Extraction of Manganese

BackPyrometallurgy is primarily used to produce ferromanganese and silicomanganese alloys.

Key Steps:

Ore preparation and sintering

Smelting in submerged arc furnaces

Alloy refining and casting

Characteristics:

High energy consumption

Suitable for large-scale alloy production

Requires consistent high-grade feed material

05Key Equipment Used in Manganese Extraction Plants

BackA reliable manganese processing plant depends on high-quality, well-matched equipment.

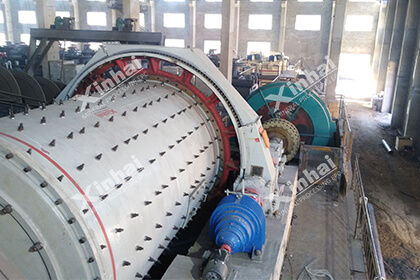

Crushing and Grinding Equipment

Jaw crushers for primary crushing

Cone crushers for secondary and tertiary crushing

Ball mills for fine grinding

Beneficiation Equipment

Jig machines for coarse manganese recovery

Spiral concentrators for medium-sized particles

Shaking tables for fine manganese particles

High-gradient magnetic separators

Auxiliary Equipment

Vibrating screens

Thickeners

Slurry pumps

Belt conveyors

Selecting durable, energy-efficient equipment significantly reduces operating costs and improves plant availability.

06Sustainable and Efficient Manganese Extraction Trends

BackModern manganese extraction focuses on:

Maximizing resource utilization

Processing low-grade and complex ores

Reducing water and energy consumption

Implementing tailings recycling solutions

Designing modular and scalable processing plants

Equipment suppliers and solution providers now offer turnkey EPC services, including ore testing, flowsheet design, equipment manufacturing, installation, and commissioning.

07Conclusion

BackThe extraction of manganese is a complex but well-established process that integrates mineral processing, hydrometallurgy, and pyrometallurgy technologies. Selecting the appropriate extraction method and equipment depends on ore characteristics, product specifications, and investment objectives.

With the growing demand for manganese in steelmaking and battery applications, efficient and sustainable manganese extraction has become more important than ever. A professionally designed manganese processing plant can significantly improve recovery rates, reduce operating costs, and maximize return on investment.

+86 182 3440 3483

+86 182 3440 3483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now