Introduction to Gold Electrowinning Process

Sheena

Sheena

Dec 23, 2025

Dec 23, 2025

485

485

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Gold-Electrowinning-Equipment-Plant

Gold electrowinning is an electrochemical process in which gold ions (Au⁺ or Au(CN)₂⁻) dissolved in solution are reduced and deposited as metallic gold onto cathode surfaces using direct current electricity.

In most gold processing circuits, electrowinning is used to recover gold from:

Carbon-in-leach (CIL) or carbon-in-pulp (CIP) elution solutions

Heap leach pregnant solutions (often combined with carbon adsorption)

Intensive cyanidation circuits for gravity gold concentrates

The deposited gold is later removed from the cathodes, dried, and smelted to produce doré bars.

01Gold Electrowinning Process Flow

BackA typical gold electrowinning circuit includes the following steps:

1. Gold Leaching and Adsorption

Gold-bearing ore is leached using a cyanide solution. Dissolved gold is then adsorbed onto activated carbon (CIP/CIL) or collected directly in solution.

2. Carbon Elution (If Applicable)

Loaded carbon is treated in an elution system to strip gold into a high-grade pregnant electrolyte solution.

3. Electrowinning

The gold-rich solution is pumped into electrowinning cells, where direct current causes gold to plate onto cathodes.

4. Cathode Harvesting

Gold-bearing cathodes (steel wool or mesh) are periodically removed from the cells.

5. Smelting and Refining

Collected cathode sludge is dried, fluxed, and smelted to produce gold doré.

02Working Principle of Gold Electrowinning

BackThe electrowinning process relies on electrolysis:

Cathode (reduction):

Gold ions gain electrons and are reduced to metallic gold.

Au(CN)₂⁻ + e⁻ → Au + 2CN⁻Anode (oxidation):

Oxidation reactions occur, typically involving oxygen evolution.

The efficiency of gold electrowinning depends on factors such as:

Gold concentration in solution

Electrical current density

Solution temperature and chemistry

Cell design and cathode material

03Gold Electrowinning Equipment

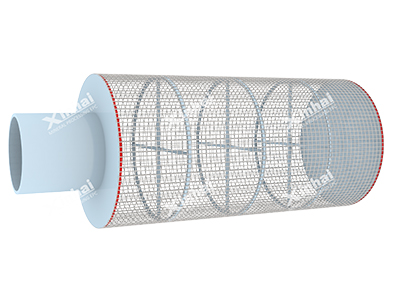

Back1. Electrowinning Cells

Electrowinning cells are rectangular tanks constructed from steel, fiberglass, or polypropylene. They are designed to ensure:

Uniform current distribution

Effective solution flow

Easy cathode removal

Cells can be installed individually or in modular banks for scalable capacity.

2. Cathodes

Common cathode materials include:

Stainless steel wool

Mild steel mesh

Expanded metal plates

Steel wool cathodes are widely used due to their high surface area, which improves gold deposition efficiency.

3. Anodes

Anodes are typically made from:

Stainless steel

Lead alloy

Mixed metal oxide (MMO) materials

They are selected for corrosion resistance and long service life.

4. Rectifier (DC Power Supply)

The rectifier converts AC power into controlled DC current. Key parameters include:

Adjustable voltage and amperage

Stable current output

Energy efficiency

5. Ancillary Systems

Additional equipment may include:

Solution pumps and piping

Heat exchangers

Flow control and monitoring instruments

04Key Process Parameters in Gold Electrowinning

BackOptimizing electrowinning performance requires careful control of several parameters:

Gold concentration: Higher concentrations improve recovery rates

Current density: Excessive current can reduce efficiency and increase power consumption

Solution temperature: Typically maintained between 40–60°C

Electrolyte composition: Free cyanide and pH must be controlled

Residence time: Adequate contact time ensures high gold recovery

05Advantages of Gold Electrowinning

BackGold electrowinning offers several operational and economic advantages:

High Recovery Efficiency

Electrowinning can achieve gold recoveries above 95% when properly designed and operated.

Compatibility with CIP/CIL Circuits

It integrates seamlessly with carbon adsorption and elution systems, making it ideal for modern gold plants.

Lower Chemical Consumption

Unlike Merrill–Crowe, electrowinning does not require zinc dust or extensive clarification systems.

Automation and Operational Simplicity

Electrowinning systems are easy to automate, reducing labor requirements and operational risk.

Compact Footprint

Electrowinning cells require less space compared with precipitation and filtration systems.

06

Back07Applications of Gold Electrowinning

BackGold electrowinning is widely used in:

CIP and CIL gold processing plants

Heap leach gold recovery circuits

Small to medium-scale gold mines

Gravity gold intensive leaching systems

Tailings reprocessing and gold recovery projects

Its flexibility makes it suitable for both greenfield projects and plant upgrades.

08Design and Investment Considerations

BackWhen designing or investing in a gold electrowinning system, key factors include:

Throughput and gold production targets

Integration with upstream leaching and elution systems

Power supply reliability and energy costs

Ease of maintenance and cathode handling

Supplier experience and after-sales support

A properly engineered electrowinning system can significantly reduce operating costs and improve overall gold recovery.

09Conclusion

BackGold electrowinning is a proven, efficient, and cost-effective gold recovery technology widely adopted in modern gold processing plants. With high recovery rates, low operating complexity, and strong compatibility with CIP/CIL circuits, it remains a cornerstone process for gold producers worldwide.

For mining investors and plant operators, selecting the right gold electrowinning equipment and process design is essential to maximizing gold recovery, minimizing operating costs, and ensuring long-term project success.

+86 182 3440 3483

+86 182 3440 3483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now