Alluvial Gold Plant Cost FAQs: Top 10 Questions Answered

Laura

Laura

May 22, 2025

May 22, 2025

15

15

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

pure gold pic

Investing in an alluvial gold plant? This guide answers 10 critical questions about costs and workflows, while detailing the beneficiation process—inspired by efficient mineral processing strategies to maximize your project.

01 What's the average capital cost for a 100 TPD alluvial gold plant?

BackA 100-ton-per-day plant typically requires $800,000–$2 million, covering equipment, site infrastructure, and permits. Modular designs (similar to industrial lithium plant setups) can reduce costs by 15–30%.

Mongolia placer gold processing plant

02 What factors drive alluvial gold plant expenses?

BackOre composition: High clay or silt content increases scrubbing costs.

Gold particle size: Fine gold may require advanced recovery methods.

Equipment efficiency: Trommels, centrifuges, and dewatering systems.

Environmental compliance: Tailings drying and water management (aligned with lithium plant standards).

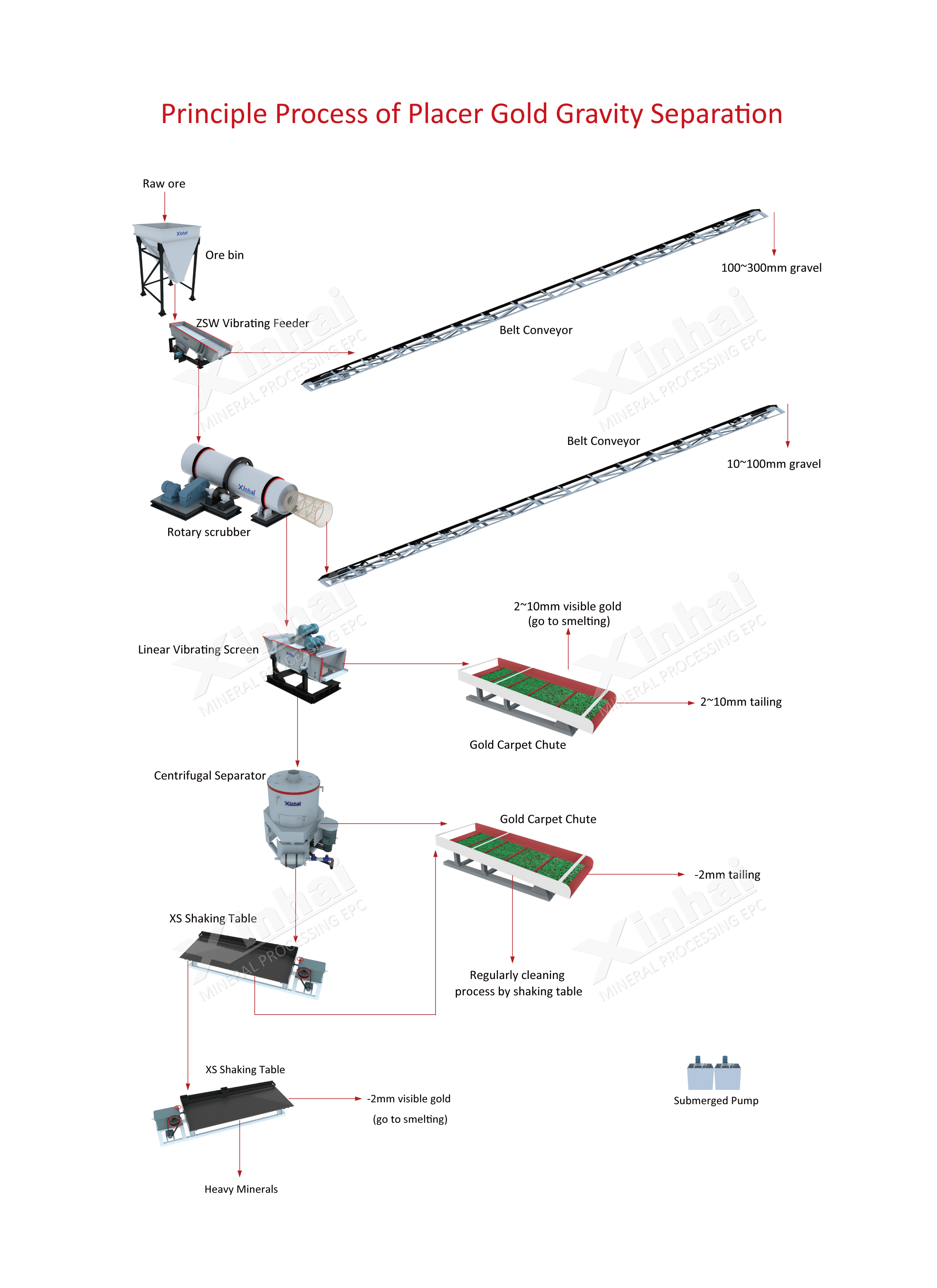

03 What's the standard beneficiation process for alluvial gold?

BackThe process includes:

Multi-Stage Screening: Remove debris and classify material (akin to lithium's two-stage closed-circuit grinding for size control).

Clay Scrubbing & De-sliming: Break down clay clusters using rotary scrubbers.

Gravity Separation: Recover coarse gold via sluices, jigs, or centrifugal concentrators.

Fine Gold Recovery: Use shaking tables or chemical methods (e.g., cyanidation) for particles<0.1mm.

Concentrate Dehydration: Employ thickeners or filter presses (similar to lithium concentrate drying).

Tailings Management: Dry stacking or sedimentation ponds to minimize environmental risks.

Placer gold gravity separation process flowchart

Placer gold gravity separation process flowchart

04 How does this differ from hard-rock gold processing?

BackAlluvial plants skip energy-intensive crushing/grinding stages, reducing energy use by 30–50%. Instead, they focus on efficient screening and gravity separation, much like lithium operations prioritize multi-stage flotation.

05 What's the cost of a centrifugal concentrator?

BackHigh-capacity units range from $50,000–$150,000. Automated models with IoT sensors improve recovery but raise upfront costs.

06 How does clay affect operating costs?

BackSticky clay demands intensive scrubbing, increasing water and energy consumption. Solutions like multi-stage screening (inspired by lithium’s closed-circuit grinding) optimize material flow and reduce wear.

07 Are modular plants cost-effective?

BackYes. Pre-engineered modules (similar to lithium plant designs) cut construction time by 40% and costs by 20–35%, starting at $400,000 for basic setups.

08 What's the ROI for a 200 TPD plant?

BackWith 85–92% recovery rates, ROI is achievable in 2–3 years under stable gold prices.

pure gold

09 How much do tailings systems cost?

BackDewatering equipment (e.g., filter presses) adds $60,000–$250,000. Dry stacking—common in lithium and gold plants—lowers long-term environmental liabilities.

10 Can renewable energy reduce operational costs?

BackSolar-hybrid systems reduce energy expenses by 20–35%, ideal for off-grid sites.

11Conclusion

BackA cost-effective alluvial gold plant hinges on multi-stage beneficiation (screening → gravity separation → dehydration) and eco-friendly tailings management. Borrowing strategies from large-scale mineral operations can enhance efficiency and compliance.

Need a tailored cost analysis? Feel free to contact us and learn more about alluvial gold mining plant cost!

+86 18234403483

+86 18234403483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now