A Complete Guide to Copper-Gold Ore Beneficiation

Laura

Laura

Dec 24, 2025

Dec 24, 2025

345

345

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Kazakhstan 1.5 million tpa copper ore flotation plant

Copper-gold ores are complex mineral deposits that contain valuable copper and gold minerals, often intergrown with gangue and sulfides. Efficient copper-gold ore beneficiation is essential to maximize recovery, improve concentrate grade, and reduce operational costs. This guide provides a step-by-step overview of the beneficiation process, equipment selection, and modern techniques used in the industry.

Understanding Copper-Gold Ores

Copper-gold ores typically contain copper sulfides such as chalcopyrite, bornite, and chalcocite, along with gold particles that may be free-milling or locked within sulfide minerals. The complexity of the ore dictates the beneficiation strategy.

Key Considerations:

1. Ore type: sulfide, oxide, or mixed

2. Particle size and mineral distribution

3. Gold occurrence: free or refractory

4. Presence of impurities: quartz, pyrite, and other sulfides

Understanding the ore characteristics is crucial to designing an effective beneficiation flow.

01Step 1: Mining and Ore Handling

BackThe beneficiation process begins with ore extraction from open-pit or underground mines.

Objectives:

1. Maintain consistent feed grade

2. Reduce dilution and waste rock

3. Prepare ore for processing

4. Run-of-mine (ROM) ore is transported to the processing plant for crushing and size reduction.

02Step 2: Crushing and Grinding

Back1. Crushing:

Primary and secondary crushers reduce ore to a suitable size for grinding. Common equipment includes:

1. Jaw crushers

2. Cone crushers

3. Impact crushers

2. Grinding:

The crushed ore is further ground to liberate copper and gold minerals. Key equipment:

1. Ball mills

2. Rod mills

3. SAG (semi-autogenous grinding) mills

Proper grinding fineness ensures effective separation while minimizing over-grinding of fine gold.

03Step 3: Classification and Screening

BackScreening and classification separate particles by size to optimize downstream beneficiation processes.

Methods:

1. Vibrating screens

2. Hydrocyclones

3. Spiral classifiers

This step ensures proper feed for flotation or gravity separation.

04Step 4: Gravity Separation

BackGravity separation is often used to recover coarse gold particles and high-density copper minerals.

Equipment:

1. Jigs

2. Shaking tables

3. Spiral concentrators

Gravity pre-concentration reduces the load on flotation circuits and improves overall recovery.

05Step 5: Flotation Beneficiation

BackFlotation is the primary method for concentrating copper and gold from complex ores.

1. Flotation Process:

Copper sulfides and gold-bearing sulfides are made hydrophobic using collectors.

Frothers create stable bubbles to float target minerals.

Depressants suppress unwanted gangue minerals.

2. Common Reagents:

1. Collectors: xanthates, dithiophosphates

2. Frothers: MIBC, pine oil

3. Modifiers: lime, sodium silicate

Flotation produces a copper-gold concentrate that is suitable for smelting or further refining.

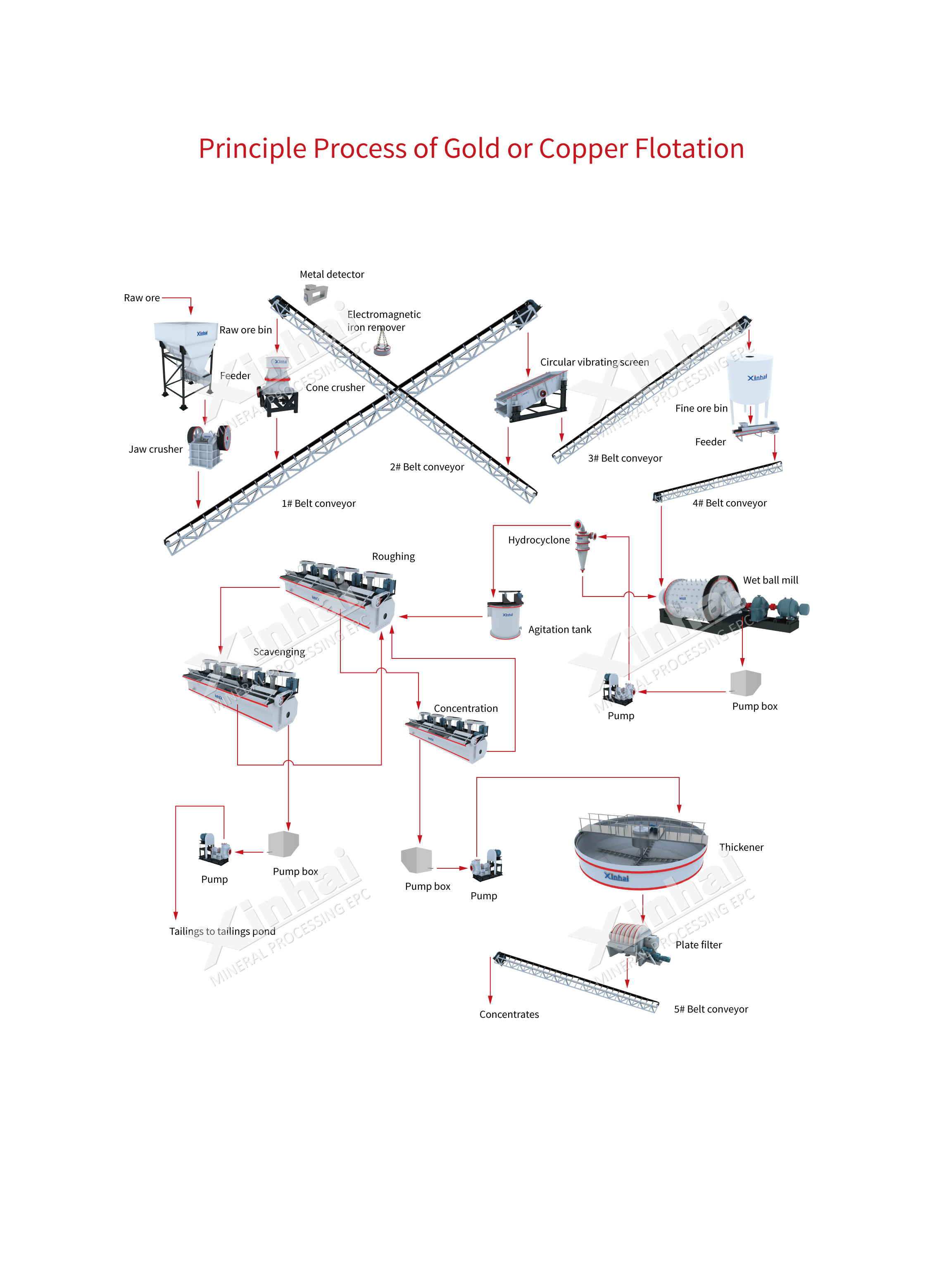

Process of Gold or Copper Flotation

06Step 6: Concentrate Dewatering and Drying

BackAfter flotation, the concentrate contains water that must be removed.

Methods:

1. Thickeners

2. Vacuum filters

3. Filter presses

4. Rotary or fluidized bed dryers

Proper dewatering ensures safe transportation and prevents losses during storage.

07Step 7: Tailings Management and Environmental Considerations

BackResponsible tailings management is essential for sustainable copper-gold beneficiation.

Key Measures:

1. Tailings thickening and disposal

2. Water recycling systems

3. Dust control

4. Monitoring heavy metal content in effluent

Modern beneficiation plants prioritize environmental compliance and sustainability.

08Step 8: Refining and Recovery of Gold

BackDepending on the ore type, additional steps may be required to recover gold from the copper-gold concentrate.

Methods:

Cyanidation for free-milling gold

Pressure oxidation or bio-oxidation for refractory gold

Smelting and electro-refining for final metal recovery

Integrated approaches maximize both copper and gold extraction.

09Conclusion

BackCopper-gold ore beneficiation is a complex but essential process that transforms raw ore into high-grade concentrates. By carefully combining crushing, grinding, gravity separation, flotation, and responsible tailings management, mining operations can maximize recovery, reduce costs, and meet market demand for copper and gold.

Efficient beneficiation requires a detailed understanding of ore characteristics, modern processing technologies, and sustainability practices, making it a critical component of successful mining operations.

+86 182 3440 3483

+86 182 3440 3483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now