A Comprehensive Guide to Manganese Processing Equipment

Laura

Laura

Mar 27, 2024

Mar 27, 2024

1466

1466

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Mineral processing equipment in transit

Manganese is a critical element used in various industries, from steel production to battery manufacturing. Its unique properties make it an essential component in many processes, making manganese processing equipment crucial for efficient operations. In this comprehensive guide, we will explore the different types of manganese processing equipment available, their functions, and key considerations when choosing the right equipment for your needs.

01Manganese Processing Equipment Overview

BackManganese processing equipment encompasses a wide range of machinery and tools designed to extract, refine, and process manganese ore into usable products. Depending on the specific application, different types of equipment may be required to achieve the desired results. The most common types of manganese processing equipment include crushers, screens, conveyors, and magnetic separators.

Crushers are used to break down large chunks of manganese ore into smaller pieces, making it easier to transport and process. There are several types of crushers available, including jaw crushers, cone crushers, and impact crushers, each with its unique advantages and drawbacks. Screens are used to separate manganese ore particles based on size, ensuring that only the desired material is processed further.

Conveyors play a crucial role in transporting manganese ore from one processing stage to another, reducing manual labor and increasing efficiency. Magnetic separators are used to remove unwanted impurities from the manganese ore, ensuring that the final product meets quality standards. Other types of equipment, such as rotary dryers, ball mills, and flotation cells, may also be used in the manganese processing process, depending on the specific requirements of the application.

02Key Considerations When Choosing Manganese Processing Equipment

BackWhen selecting manganese processing equipment, several key factors must be considered to ensure optimal performance and efficiency. These factors include the type and size of the manganese ore, the desired end product, processing capacity, and budget constraints. By carefully evaluating these factors, you can choose the right equipment that meets your specific needs and provides the best value for your investment.

The type and size of the manganese ore play a significant role in determining the type of processing equipment required. Different ores may require different processing methods, so it is essential to understand the characteristics of the ore before selecting equipment. The desired end product also influences the choice of equipment, as some processes may be more suitable for producing certain products than others.

Processing capacity is another critical factor to consider when choosing manganese processing equipment. The equipment must be able to handle the volume of ore processed efficiently to avoid bottlenecks and ensure smooth operations. Additionally, budget constraints may limit the selection of equipment, so it is essential to balance performance with cost-effectiveness.

03Types of Manganese Processing Equipment

BackThere are several types of manganese processing equipment available, each designed for specific applications and processing requirements. Some of the most common types of equipment include:

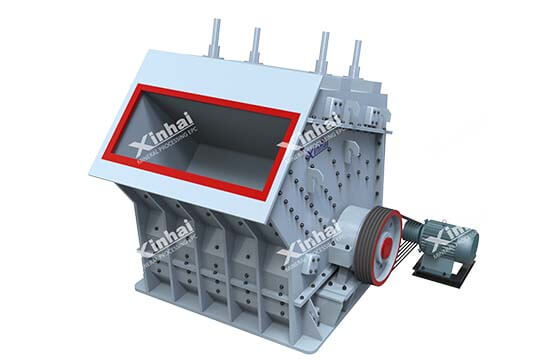

1. Crushers: Crushers are used to break down large chunks of manganese ore into smaller pieces for further processing. Jaw crushers, cone crushers, and impact crushers are commonly used in manganese processing operations.

Impact crusher

2. Screens: Screens are used to separate manganese ore particles based on size, ensuring that only the desired material is processed further. Vibrating screens, trommel screens, and inclined screens are commonly used in manganese processing plants.

Screening machine

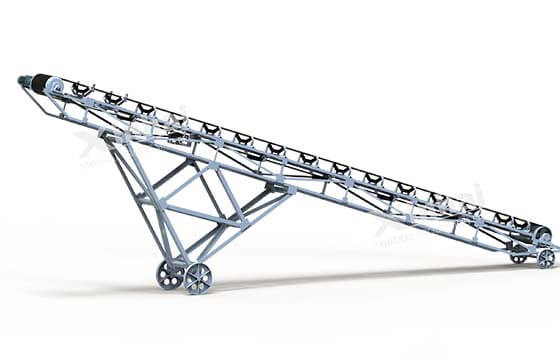

3. Conveyors: Conveyors are used to transport manganese ore from one processing stage to another, reducing manual labor and increasing efficiency. Belt conveyors, screw conveyors, and bucket elevators are commonly used in manganese processing operations.

Portable belt conveyor

4. Magnetic Separators: Magnetic separators are used to remove unwanted impurities from the manganese ore, ensuring that the final product meets quality standards. Overband magnets, drum magnets, and magnetic pulleys are commonly used in manganese processing plants.

Magnetic separator

5. Rotary Dryers: Rotary dryers are used to dry manganese ore before further processing, reducing moisture content and improving efficiency. Rotary drum dryers are commonly used in manganese processing operations.

6. Ball Mills: Ball mills are used to grind manganese ore into fine particles, facilitating the extraction of manganese from the ore. Ball mills are commonly used in manganese processing plants.

Ball mill

7. Flotation Cells: Flotation cells are used to separate manganese ore particles based on their hydrophobicity, allowing for the selective extraction of manganese from the ore. Flotation cells are commonly used in manganese processing operations.

Flotation cell

04Conclusion

BackManganese processing equipment plays a crucial role in extracting, refining, and processing manganese ore into usable products. By understanding the different types of equipment available, their functions, and key considerations when choosing equipment, you can ensure optimal performance and efficiency in your manganese processing operations. Whether you are involved in steel production, battery manufacturing, or any other industry that relies on manganese, selecting the right processing equipment is essential for success. By following this comprehensive guide, you can make informed decisions and maximize the value of your investment in manganese processing equipment.

Contact us for a free consultation on your manganese processing needs.

+86 182 3440 3483

+86 182 3440 3483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now