Antimony Processing Plant Design and Cost Analysis

Sheena

Sheena

Jan 20, 2026

Jan 20, 2026

273

273

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Antimony-design-processing-plant

This article provides a comprehensive overview of antimony processing plant design principles, typical process flowsheets, key equipment selection, and a detailed cost analysis, helping investors and project developers evaluate technical feasibility and capital requirements.

01Overview of Antimony Ores and Processing Challenges

Back1.1 Common Antimony Ore Types

Antimony occurs mainly in the following forms:

Sulfide ores: Stibnite (Sb₂S₃), the most economically important mineral

Oxide ores: Cervantite, valentinite (less common)

Complex polymetallic ores: Associated with gold, mercury, arsenic, or lead

Among these, antimony sulfide ores dominate commercial mining, and their processing typically relies on gravity separation, flotation, or a combination of both.

1.2 Processing Challenges

Key technical challenges in antimony processing include:

Fine-grained mineral dissemination

High density but brittle mineral structure

Sensitivity to over-grinding

Environmental risks from arsenic and sulfur

These factors must be addressed during plant design to achieve high recovery, stable operation, and regulatory compliance.

02Antimony Processing Plant Design Principles

BackA well-designed antimony processing plant must balance metallurgical performance, capital efficiency, and operational simplicity. The following principles guide effective plant design.

2.1 Ore Characterization as the Design Foundation

Before any process design, detailed test work is essential, including:

Chemical composition analysis

Mineralogical studies (liberation size, associations)

Gravity and flotation test results

Grindability and abrasiveness tests

Accurate ore characterization directly determines the process route, equipment sizing, and cost estimation accuracy.

2.2 Process Route Selection

The most common antimony processing routes include:

Gravity separation flowsheet

Flotation-based flowsheet

Combined gravity + flotation flowsheet

Gravity separation is preferred when stibnite shows sufficient liberation at coarse sizes, while flotation is used for fine or complex ores.

03Typical Antimony Processing Plant Flowsheet

Back3.1 Crushing and Screening Section

The processing plant begins with primary and secondary crushing to reduce run-of-mine (ROM) ore to manageable sizes.

Jaw crusher for primary crushing

Cone or impact crusher for secondary crushing

Vibrating screens for size classification

Design considerations:

Avoid excessive fines generation

Ensure stable feed size for grinding

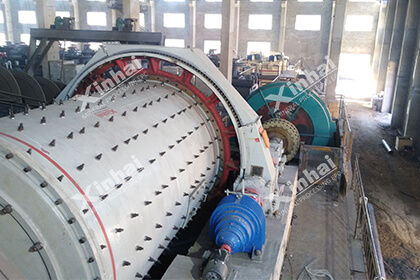

3.2 Grinding and Classification

Grinding is one of the most critical stages in antimony processing.

Common configurations:

Ball mill + hydrocyclone

Rod mill + ball mill (for coarse liberation)

Key design objectives:

Achieve optimal liberation without over-grinding

Protect stibnite from sliming

Control particle size distribution precisely

Energy consumption in this stage significantly impacts operating costs.

3.3 Gravity Separation Circuit

For coarse and medium-grained stibnite, gravity separation offers:

Low operating cost

Simple flowsheet

High selectivity

Typical gravity equipment includes:

Jig separators

Spiral concentrators

Shaking tables

Gravity concentrates are often upgraded further or directly sold if grade meets market requirements.

3.4 Flotation Circuit

For fine-grained or complex antimony ores, flotation is essential.

Flotation design includes:

Rougher, scavenger, and cleaner stages

pH control and reagent dosing

Selective collectors and depressants

Flotation allows higher recovery but increases capital and operating costs due to reagent consumption and process control requirements.

3.5 Concentrate Dewatering and Tailings Management

Final antimony concentrate is processed through:

Thickener

Filter press or vacuum filter

Drying (if required by downstream processing)

Tailings management must comply with environmental regulations, often requiring:

Tailings thickening

Lined tailings storage facilities

Water recycling systems

04Antimony Processing Plant Capacity Design

BackPlant capacity is typically defined in tons per day (TPD) and must align with mine production plans.

Typical capacity ranges:

Small-scale plant: 100–300 TPD

Medium-scale plant: 500–1,000 TPD

Large-scale plant: 2,000+ TPD

Capacity selection affects:

Equipment size and redundancy

Capital expenditure (CAPEX)

Unit processing cost

Modular or phased expansion designs are often recommended to reduce upfront risk.

05Capital Cost Analysis of Antimony Processing Plants

Back5.1 Major CAPEX Components

Antimony processing plant capital cost typically includes:

Process equipment

Crushers, mills, flotation machines, gravity separators

Auxiliary systems

Pumps, compressors, reagent systems

Civil works

Foundations, buildings, structural steel

Electrical and control systems

MCCs, automation, instrumentation

Installation and commissioning

Mechanical and electrical installation

Engineering and project management

5.2 Typical CAPEX Range

While costs vary by region and project complexity, approximate ranges are:

Small plant (300 TPD): USD 3–6 million

Medium plant (1,000 TPD): USD 8–15 million

Large plant (2,000+ TPD): USD 20–40 million

Factors influencing capital cost include:

Ore hardness and complexity

Degree of automation

Environmental protection requirements

Local labor and construction costs

06Operating Cost (OPEX) Analysis

BackOperating cost determines long-term project profitability.

6.1 Key OPEX Components

Energy consumption

Crushing and grinding dominate power usage

Consumables

Grinding media

Flotation reagents

Labor

Operators, technicians, management

Maintenance

Spare parts and wear components

Water and tailings management

6.2 Typical Operating Cost Range

Depending on plant scale and process complexity:

Gravity-dominated flowsheet: USD 10–18 per ton of ore

Flotation-based flowsheet: USD 18–30 per ton of ore

Reducing grinding energy and reagent consumption is the most effective way to control OPEX.

07Conclusion

BackAntimony processing plant design and cost analysis require a comprehensive understanding of ore characteristics, processing technologies, and economic constraints. From crushing and grinding to gravity separation and flotation, each design decision directly impacts capital investment, operating cost, and overall project profitability.

A well-designed antimony processing plant—supported by thorough test work, realistic cost estimation, and experienced engineering partners—can achieve high recovery, stable operation, and attractive financial returns. As global demand for antimony continues to grow, professionally designed and cost-optimized processing plants will play a crucial role in ensuring sustainable and competitive production.

+86 182 3440 3483

+86 182 3440 3483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now