Flotation vs. Gravity in Antimony Processing: Which Yields Better Results?

Sheena

Sheena

Aug 20, 2025

Aug 20, 2025

1649

1649

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

This article compares flotation and gravity separation in the context of antimony processing, analyzing their working principles, advantages, limitations, and suitable application scenarios. Whether you are planning a new processing plant or optimizing an existing operation, understanding the strengths and weaknesses of each method can help guide your decision.

01Gravity Separation in Antimony Processing

Back1. Principle and Equipment

Gravity separation uses the difference in specific gravity between antimony minerals and gangue materials to achieve separation. The method is especially effective when the mineral is coarse-grained and liberated.

Common equipment includes:

Shaking tables

Spiral concentrators

Jig machines

Dense media separators

2. Advantages of Gravity Separation

Simple and Cost-Effective: Gravity processes generally require less infrastructure and chemical input.

Environmentally Friendly: No need for chemical reagents, reducing environmental impact.

Effective for Coarse Particles: Ideal for stibnite particles above 0.1 mm.

3. Limitations of Gravity Separation

Lower Recovery for Fine-Grained Ores: Inefficient when particles are below 0.074 mm.

Not Suitable for Complex Ores: Struggles with ores containing antimony interlocked with sulfide or oxide gangue.

Limited Upgrade Ratio: Often cannot reach concentrate grades suitable for metallurgy without secondary treatment.

4. Best Use Case

Gravity separation is ideal for coarse stibnite ores with minimal impurities and high liberation.

02Flotation in Antimony Processing

Back1. Principle and Equipment

Flotation involves the selective attachment of antimony minerals to air bubbles in a pulp, allowing them to float while gangue sinks. This technique works particularly well with fine-grained or complex sulphide ores.

Key equipment includes:

Flotation cells (mechanical or pneumatic)

Conditioning tanks

Reagent dosing systems

2. Common Flotation Reagents for Antimony:

Collectors: Such as xanthates or dithiophosphates for sulfide minerals.

Frothers: To create stable froth (e.g., pine oil, MIBC).

Depressants: To suppress gangue minerals like quartz or calcite.

3. Advantages of Flotation

High Recovery Rate: Can recover up to 90% of fine antimony minerals.

Effective on Complex Ores: Performs well even when stibnite is finely disseminated.

Adjustable Selectivity: Reagents allow for separation of closely associated minerals.

4. Limitations of Flotation

Higher Operating Costs: Due to reagent use and energy-intensive aeration.

Environmental Concerns: Chemical reagents can pose challenges in waste management.

Requires Fine Grinding: Liberation often requires ball or rod milling, increasing CAPEX and OPEX.

5. Best Use Case

Flotation is preferred for fine-grained stibnite ores or ores with complex mineral associations.

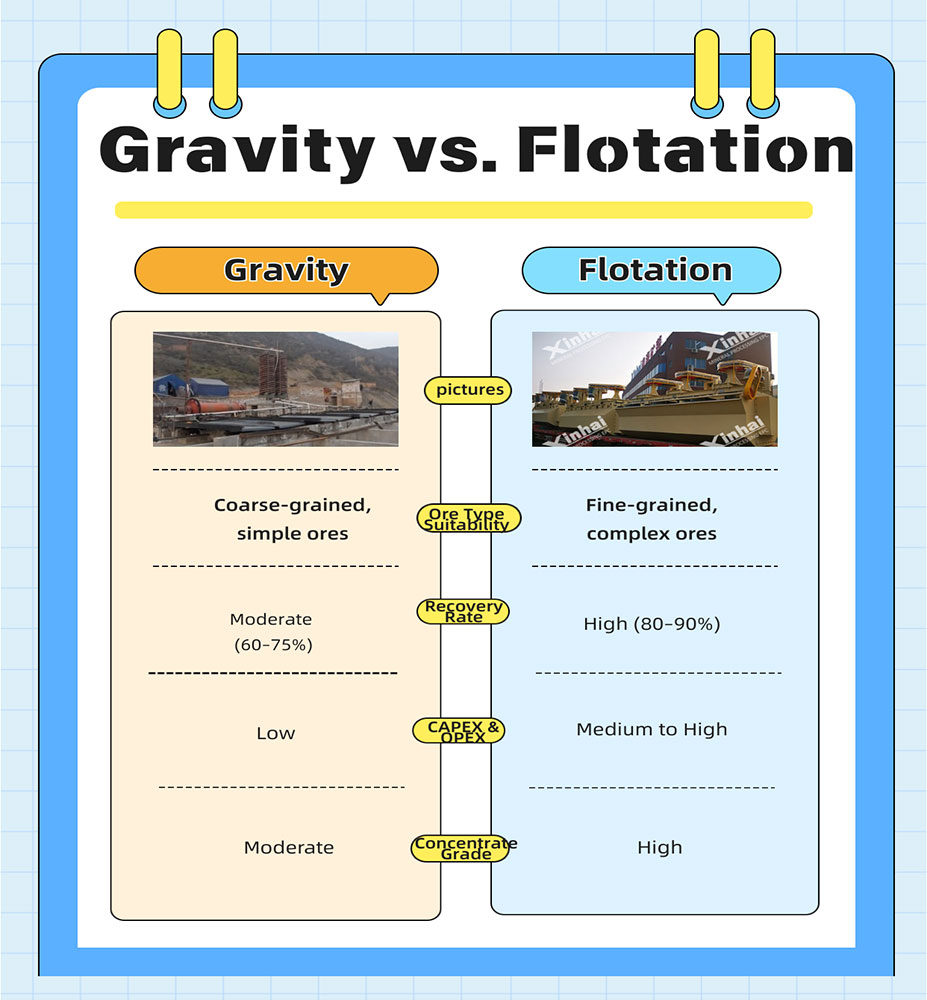

03Comparative Analysis: Gravity vs. Flotation

Back| Factor | Gravity Separation | Flotation |

|---|---|---|

| Ore Type Suitability | Coarse-grained, simple ores | Fine-grained, complex ores |

| Recovery Rate | Moderate (60–75%) | High (80–90%) |

| CAPEX & OPEX | Low | Medium to High |

| Environmental Impact | Low (no chemicals) | Medium to High (due to reagents) |

| Concentrate Grade | Moderate | High |

| Processing Complexity | Simple | Technically intensive |

| Scalability | Good for small-scale or remote operations | Suitable for large-scale industrial plants |

04Hybrid Approaches: Combining Gravity and Flotation

BackIn some cases, combining both methods yields the best results. A common approach is:

Pre-concentration using gravity separation to remove coarse gangue and recover heavy stibnite particles.

Follow-up flotation to treat the fine fraction and improve overall recovery.

This combination:

Reduces flotation circuit load

Lowers reagent consumption

Increases plant efficiency

05Choosing the Right Method: Key Decision Factors

BackWhen evaluating antimony beneficiation methods, consider the following:

Ore Texture and Grade: Fine textures require flotation; coarse ores can be gravity-fed.

Project Scale: Small operations may favor gravity; larger ones justify flotation investment.

Environmental Regulations: Stricter regions may limit flotation due to chemical usage.

Infrastructure Availability: Water, power, and skilled labor affect method feasibility.

Downstream Requirements: Smelters may demand high-grade concentrates, favoring flotation.

06Trends in Antimony Ore Processing Technology

BackAs global demand for antimony grows—especially in flame retardants, semiconductors, and military applications—processing technology continues to evolve.

Emerging trends include:

Eco-friendly reagents: To reduce environmental footprint.

Sensor-based ore sorting: As a pre-concentration tool.

Automation and AI: For optimizing flotation parameters in real-time.

Recycling of antimony-rich waste streams: From lead-acid batteries and smelting residues.

07Conclusion: Which Method Is Better?

BackThere is no one-size-fits-all solution in antimony ore processing. Instead, the choice between gravity separation and flotation depends on ore characteristics, processing objectives, and project context.

Choose gravity separation for simple, coarse, high-liberation ores, especially in remote or small-scale scenarios.

Opt for flotation when dealing with fine, complex ores that demand high recovery and concentrate grade.

In many modern operations, a combined approach proves most efficient—leveraging gravity for pre-concentration and flotation for final cleaning. Ultimately, a detailed mineralogical study and pilot testing are essential to define the most effective processing strategy.

+86 182 3440 3483

+86 182 3440 3483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now