What Is Iron Ore Processing? Methods, Equipment & Steps

Laura

Laura

Feb 17, 2026

Feb 17, 2026

10

10

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

The shipment of the iron ore flotation machine

Iron ore processing is a key activity in the mining and steel industries. It involves a series of physical and chemical methods used to transform raw iron ore into a concentrated form suitable for steel production. Efficient iron ore processing improves mineral recovery, reduces operating costs, and ensures consistent product quality.

This article explains what iron ore processing is, the methods used, the equipment involved, and the step-by-step process from mining to final product.

01What Is Iron Ore Processing?

BackIron ore processing refers to the treatment of mined iron ore to remove impurities and increase the iron content. The goal is to produce high-grade iron ore concentrate or pellets that can be used in blast furnaces or direct reduction processes.

Processing typically includes crushing, grinding, beneficiation, dewatering, and sometimes pelletizing or sintering.

02Types of Iron Ore Processed

BackDifferent iron ore types require different processing methods:

Hematite ore – often processed using crushing, screening, and magnetic separation

Magnetite ore – usually requires fine grinding and magnetic separation

Low-grade iron ore – needs advanced beneficiation techniques to improve iron content

03Iron Ore Processing Methods

BackSeveral methods are used depending on ore characteristics and desired product quality.

1. Crushing and Grinding

Crushing reduces large ore chunks into smaller fragments, while grinding further reduces particle size to liberate iron minerals.

Common methods include:

Jaw and gyratory crushing

Cone and impact crushing

Ball mills, rod mills, and SAG mills

2. Magnetic Separation

Magnetic separation is widely used to separate iron minerals from gangue material. Low-intensity and high-intensity magnetic separators are selected based on ore type.

3. Gravity Separation

Gravity separation methods rely on density differences between iron minerals and waste rock. Equipment includes jigs, spirals, and shaking tables.

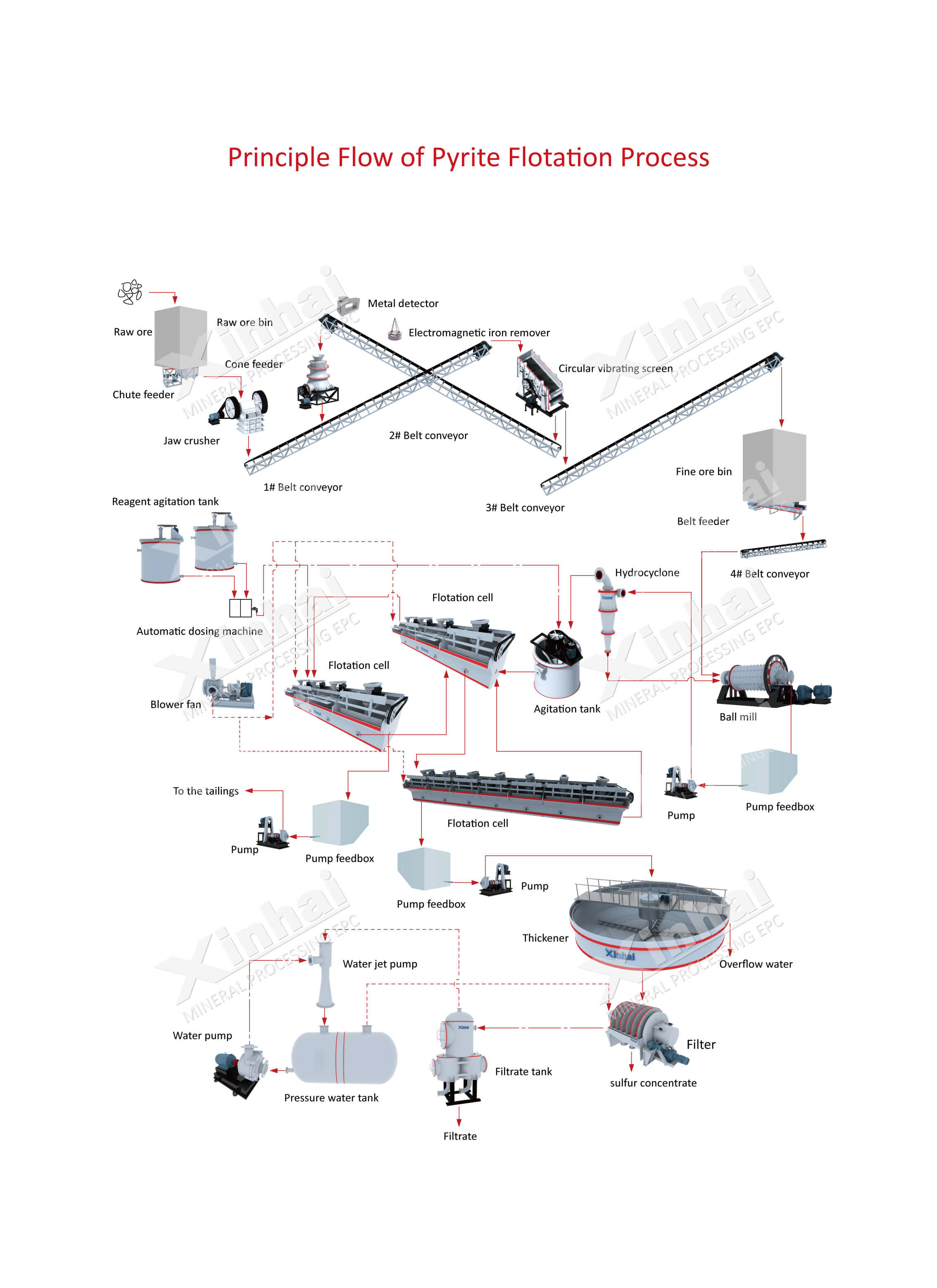

4. Froth Flotation

Flotation is used mainly for low-grade or complex ores. Chemical reagents selectively separate iron minerals from impurities.

5. Dewatering and Drying

After beneficiation, dewatering removes excess moisture using thickeners, filters, and dryers to prepare the product for transport or pelletizing.

04Iron Ore Processing Equipment

BackIron ore processing plants use a wide range of equipment, including:

1. Crushers (jaw, cone, gyratory)

2. Grinding mills (ball mills, SAG mills)

3. Vibrating screens and feeders

4. Magnetic separators

5. Gravity separation equipment

6. Flotation machines

7. Thickeners and filters

Each piece of equipment plays a critical role in maintaining plant efficiency and product quality.

05Step-by-Step Iron Ore Processing

BackStep 1: Mining and Ore Handling

Iron ore is extracted from open-pit or underground mines and transported to the processing plant.

Step 2: Crushing and Screening

The ore is crushed and screened to achieve suitable size for grinding and separation.

Step 3: Grinding and Classification

Crushed ore is ground into fine particles and classified to ensure proper size distribution.

Step 4: Beneficiation and Separation

Iron minerals are separated from impurities using magnetic separation, gravity methods, or flotation.

Step 5: Dewatering and Drying

Moisture is removed to improve handling, storage, and downstream processing.

Step 6: Pelletizing or Sintering (Optional)

Fine iron ore concentrate may be converted into pellets or sinter for steelmaking.

The flotation process flow of pyrite

06Importance of Iron Ore Processing

BackEfficient iron ore processing offers several benefits:

Higher iron recovery rates

Lower energy and water consumption

Reduced environmental impact

Improved steelmaking performance

Cost-effective operations

07Modern Trends in Iron Ore Processing

BackRecent advancements include:

Automation and digital process control

Energy-efficient grinding technologies

Advanced magnetic separation systems

Sustainable water management practices

08Conclusion

BackIron ore processing is essential for producing high-quality raw materials for the steel industry. By understanding the methods, equipment, and step-by-step process, mining operations can optimize efficiency, improve recovery, and reduce costs.

A well-designed iron ore processing plant ensures consistent performance and long-term sustainability in modern mining operations.

+86 182 3440 3483

+86 182 3440 3483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now