Why Ore Beneficiation Testing is Essential Before Building a Mineral Processing Plant?

Sheena

Sheena

Sep 24, 2025

Sep 24, 2025

938

938

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

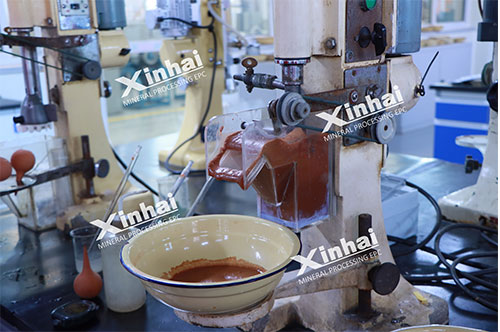

Pictures-of-mineral-processing-laboratory

In the mining industry, a successful project depends not only on the size of the ore reserve but also on how effectively the ore can be processed into marketable products. Ore beneficiation testing—also referred to as mineral processing test or ore dressing test—is the scientific foundation for designing and building a mineral processing plant.

Skipping this critical step often results in poor recovery, costly plant modifications, and even financial failure. This article explains why ore beneficiation testing is indispensable, what it involves, and how it ensures that mining investments generate profitable returns while meeting environmental standards.

01What is Ore Beneficiation Testing?

BackOre beneficiation testing refers to a series of laboratory and pilot-scale experiments designed to determine how an ore responds to different mineral processing methods. The aim is to establish the most efficient process flowsheet, define key operating parameters, and evaluate the potential economic outcomes of processing the ore.

Typical information obtained includes:

Mineral composition and distribution

Ore grindability and liberation size

Response to separation methods (flotation, gravity, magnetic separation, etc.)

Concentrate grade and recovery rate

Tailings properties and environmental considerations

In short, ore beneficiation testing provides the knowledge needed to turn a mineral deposit into a viable mining project.

02Understanding the Ore's Characteristics

BackEvery ore body is unique. Even within the same mining region, mineral composition can differ dramatically. Ore beneficiation testing helps uncover these differences and ensures that processing decisions are based on data rather than assumptions.

Key insights gained from ore characterization:

Mineralogy: Identify valuable and gangue minerals present.

Grain size and liberation: Determine how fine the ore needs to be ground for separation.

Mineral associations: Understand how minerals are interlocked and how difficult they are to separate.

Variability: Assess ore characteristics across different zones of the deposit.

Without this knowledge, selecting the right processing method is like shooting in the dark.

03Determining the Best Processing Route

BackDifferent ores require different beneficiation processes. For example:

Flotation is suitable for sulfide minerals such as copper or antimony.

Gravity separation works well for coarse particles and dense minerals like gold or chromite.

Magnetic separation is effective for magnetite-rich ores.

Through beneficiation testing, engineers can identify the best processing method or a combination of methods, along with the optimal grind size, reagent dosage, and operating conditions.

Benefits of defining the processing route:

Maximized recovery: More valuable minerals are captured.

Optimized costs: Reduced energy and reagent consumption.

Reduced risk: Avoids expensive redesigns after plant construction.

Copying a neighboring mine’s process often leads to failure, since ore properties are rarely identical. Ore beneficiation testing eliminates this risk.

04Assessing Economic Feasibility

BackFrom an investor's standpoint, ore beneficiation testing is the ultimate reality check. It reveals whether the deposit can produce marketable concentrates at a profit.

Two critical metrics are obtained:

Concentrate grade: Determines the selling price of the product.

Recovery rate: Indicates how much of the valuable mineral can be extracted.

If concentrate quality is poor or recovery is low, the ore body may not justify investment. On the other hand, strong test results can attract financing and secure regulatory approval.

Thus, ore beneficiation testing answers the question every investor asks: Can this mine make money?

05Providing Data for Plant Design

BackDesigning a mineral processing plant without test data is like building on sand. Engineers rely on beneficiation results to size equipment, design the flowsheet, and plan utility consumption.

Key design parameters include:

Grinding mill specifications (size, power, capacity)

Flotation cell type and number

Thickener and filter design

Energy, water, and reagent consumption rates

Tailings handling and storage requirements

Accurate test data ensures that the plant operates efficiently from day one, avoiding costly retrofits and operational bottlenecks.

06Supporting Environmental Compliance and Resource Utilization

BackMining projects today must balance profitability with environmental responsibility. Ore beneficiation testing helps companies meet both goals.

Environmental and efficiency benefits:

Improved tailings management: Optimized disposal reduces pollution risk.

Secondary recovery: Valuable by-products, such as rare earths or cobalt, can be extracted from tailings.

Reduced footprint: Efficient processes lower energy and water consumption.

By incorporating environmental factors into beneficiation test work, companies can reduce risks, improve ESG performance, and even enhance project economics by recovering additional elements.

07The Risks of Skipping Ore Beneficiation Testing

BackCompanies that bypass ore beneficiation testing face significant risks, including:

Incorrect process selection → Poor recovery and low-grade products.

Financial losses → Plants require costly modifications or fail to operate profitably.

Resource wastage → Valuable minerals are lost permanently.

Environmental hazards → Poor tailings handling causes pollution and regulatory penalties.

The cost of testing is small compared to the losses from building a plant on unreliable assumptions.

08Conclusion

BackOre beneficiation testing is not an expense—it is an investment in project success. By understanding the ore's characteristics, determining the best processing route, evaluating economic potential, and providing reliable design data, beneficiation testing minimizes risks and maximizes value. It also ensures compliance with environmental regulations and promotes sustainable resource use.

For mining companies, skipping this step is a gamble with potentially disastrous outcomes.

If you are planning a new mining project or considering investment in a processing plant, start with ore beneficiation testing. Partner with professional laboratories and engineering firms that specialize in mineral processing research.

+86 182 3440 3483

+86 182 3440 3483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now