What Is the Flotation of Phosphate Ores? Guide to Beneficiation

Laura

Laura

Jun 28, 2025

Jun 28, 2025

1745

1745

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

BF Flotation Cells

Phosphate ores are vital for producing fertilizers, animal feed, and industrial chemicals. However, raw phosphate rock is mixed with impurities like silica, clay, and carbonates. To extract usable phosphate, miners rely on flotation—a process that separates valuable minerals from waste using bubbles and chemicals. In this guide, we’ll break down how phosphate flotation works, step by step.

01 Why Use Flotation for Phosphate Ores?

BackEfficiency: Flotation effectively separates fine-grained phosphate from impurities.

Flexibility: Works for both sedimentary and igneous phosphate deposits.

Cost-Effective: Maximizes phosphate recovery while minimizing energy use.

02 The Phosphate Beneficiation Process: Step-by-Step

Back1. Crushing and Grinding

Phosphate ore is first crushed into small pieces and ground into a fine powder. This step "liberates" phosphate minerals from surrounding rock, making them easier to separate later.

2. Conditioning with Reagents

The ground ore is mixed with water and chemicals in a conditioning tank:

Collectors: Fatty acids or fuel oil coat phosphate particles, making them water-repellent.

Depressants: Starch or sodium silicate prevent silica and carbonates from reacting.

pH Adjusters: Sulfuric acid or soda ash optimize the slurry’s acidity for flotation.

3. Flotation Separation

The slurry is pumped into flotation cells, where air bubbles are injected.

Direct Flotation: Phosphate particles attach to bubbles and rise to the surface as froth, which is skimmed off.

Reverse Flotation: Impurities like silica are floated away, leaving phosphate at the bottom.

How It Works: Hydrophobic (water-repellent) phosphate sticks to bubbles, while hydrophilic (water-loving) waste sinks.

4. Dewatering and Drying

Thickeners: Remove excess water from the phosphate concentrate.

Filters and Dryers: Produce a dry, market-ready product.

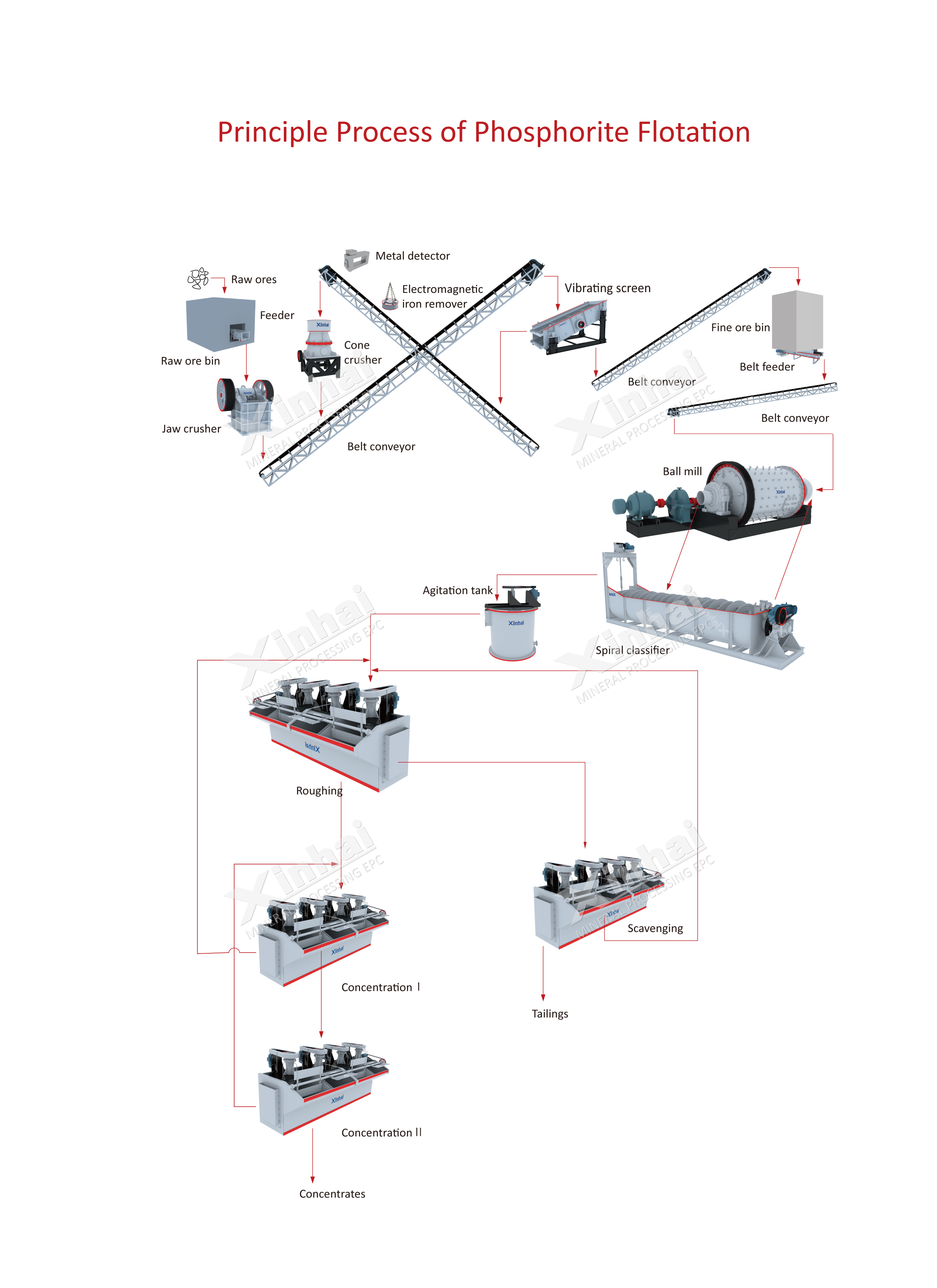

Principle Process of Phosphate Flotation

03 Key Challenges in Phosphate Flotation

BackComplex Ore Types: Some ores contain carbonates or iron oxides that interfere with separation.

Reagent Costs: Chemicals like fatty acids can be expensive.

Water Management: Recycling water from the process reduces environmental impact.

04 Innovations in Phosphate Flotation

BackColumn Flotation: Tall, pressurized columns improve separation precision for fine particles.

Eco-Friendly Reagents: Biodegradable chemicals reduce toxicity in wastewater.

Automated Control Systems: Sensors adjust reagent doses in real time for optimal recovery.

05 Environmental Considerations

BackTailings Management: Waste sludge (tailings) is stored in lined ponds to prevent groundwater contamination.

Water Recycling: Modern plants reuse up to 85% of process water.

Dust Control: Spray systems minimize airborne particles during crushing and drying.

06 FAQs

BackQ: Can flotation recover low-grade phosphate ores?

A: Yes! Flotation is ideal for ores with as little as 5–10% phosphate content.

Q: What happens to the waste after flotation?

A: Tailings are often repurposed for land reclamation or construction materials.

Q: How much energy does the process use?

A: Flotation consumes about 30–50% of a plant’s total energy, mainly for grinding and pumping.

07Conclusion

BackFlotation is the backbone of phosphate beneficiation, turning raw ore into a product essential for global agriculture. By combining chemistry, physics, and smart engineering, this process efficiently separates phosphate from stubborn impurities. As demand for fertilizers grows, innovations like automated systems and greener reagents are ensuring phosphate mining remains both productive and sustainable.

Feel free to contact us and learn more about phosphate processing solutions!

+86 182 3440 3483

+86 182 3440 3483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now