The Ultimate Guide to Graphite Beneficiation Machines

Laura

Laura

May 29, 2024

May 29, 2024

1212

1212

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

Ball Mill - The Ultimate Guide to Graphite Beneficiation Machines

Graphite is a mineral that has been used for centuries in various industries, including the production of pencils, lubricants, and batteries. However, in recent years, the demand for graphite has increased significantly due to its use in emerging technologies such as lithium-ion batteries and fuel cells. As a result, the need for graphite beneficiation machines has also grown, as these machines are essential for processing raw graphite ore into a usable form.

In this ultimate guide to graphite beneficiation machines, we will explore the various types of machines used in the beneficiation process, their functions, and how they contribute to the overall efficiency of graphite production. We will also discuss the importance of graphite beneficiation and how it can impact the quality and purity of the final product.

01Graphite Beneficiation Process

BackBefore we delve into the types of machines used in graphite beneficiation, it is essential to understand the beneficiation process itself. Graphite beneficiation is the process of removing impurities and improving the quality of graphite ore through various methods such as crushing, grinding, flotation, and magnetic separation.

The beneficiation process begins with the crushing and grinding of raw graphite ore to reduce its size and prepare it for further processing. This is typically done using crushers and mills, which break down the ore into smaller particles. Once the ore has been crushed and ground, it is then subjected to flotation, a process that separates graphite from other minerals based on their hydrophobicity.

Flotation is a critical step in the beneficiation process as it allows for the separation of graphite from impurities such as silicate minerals and sulfide ores. Once the graphite has been separated, it is further processed using techniques such as magnetic separation to remove any remaining impurities and improve the purity of the final product.

02Types of Graphite Beneficiation Machines

BackThere are several types of machines used in graphite beneficiation, each serving a specific function in the beneficiation process. Some of the most common machines used in graphite beneficiation include:

1. Crushers

Crushers are used to break down raw graphite ore into smaller particles, making it easier to process and extract graphite from the ore. There are several types of crushers available, including jaw crushers, cone crushers, and impact crushers.

2. Mills

Mills are used to grind crushed graphite ore into a fine powder, which is then subjected to further processing. Common types of mills used in graphite beneficiation include ball mills, rod mills, and vertical mills.

3. Flotation machines

Flotation machines are used to separate graphite from other minerals based on their hydrophobicity. There are several types of flotation machines available, including mechanical flotation cells, column flotation cells, and pneumatic flotation machines.

4. Magnetic separators

Magnetic separators are used to remove impurities from graphite ore through magnetic separation. This process involves passing the ore through a magnetic field, which attracts and separates magnetic particles from non-magnetic particles.

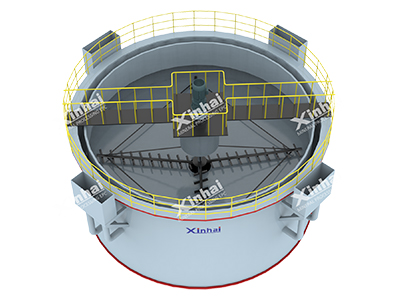

5. Dewatering machines

Dewatering machines are used to remove excess water from the graphite concentrate, making it easier to handle and transport. Common types of dewatering machines include vacuum filters, belt presses, and centrifuges.

03Importance of Graphite Beneficiation

BackGraphite beneficiation is essential for improving the quality and purity of graphite ore, which directly impacts the performance and efficiency of the final product. By removing impurities and processing raw graphite ore into a usable form, beneficiation machines play a crucial role in ensuring the quality and consistency of graphite production.

One of the key benefits of graphite beneficiation is the ability to produce high-quality graphite concentrates that meet the specifications of end-users. This is particularly important in industries such as lithium-ion batteries and fuel cells, where the purity of graphite is critical for optimal performance.

Additionally, graphite beneficiation helps to increase the overall efficiency of graphite production by reducing waste and improving the recovery of valuable graphite particles. By using beneficiation machines to process raw graphite ore, manufacturers can maximize the yield of high-quality graphite concentrates while minimizing the environmental impact of graphite mining and processing.

04In Conclusion

BackGraphite beneficiation machines play a vital role in the production of high-quality graphite concentrates that meet the specifications of end-users in various industries. By understanding the different types of machines used in graphite beneficiation and their functions, manufacturers can optimize the efficiency and quality of graphite production, ultimately benefiting both the industry and the environment.

Contact us for a personalized consultation on graphite beneficiation machine options for your specific needs!

+86 182 3440 3483

+86 182 3440 3483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now