Mineral Processing Equipment - Introduction to Several Key Types of Equipment

zeki

zeki

Sep 30, 2025

Sep 30, 2025

697

697

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

In a mineral processing system, the technological level and operational reliability of key equipment are the core factors determining production efficiency, operating costs, and ultimate economic benefits. Prudent evaluation and precise selection of equipment are the cornerstones for maximizing the investment value of a project.

01Equipment Required for Mineral Processing

Back

· Crushing Equipment -- Jaw Crusher, Hammer Crusher

· Screening Equipment -- Linear Vibrating Screen

· Grinding Equipment -- Ball Mill, Rod Mill

· Classification Equipment -- High Weir Spiral Classifier

· Flotation Equipment -- Flotation Machine

· Gravity Separation Equipment -- Jig, Shaking Table

· Cyanidation Equipment -- Leaching Agitation Tank

· Thickening Equipment -- Thickener

02Crusher

BackWorking Principle: The core working principle of a crusher is to apply external forces (such as extrusion, impact, shearing, and grinding) to break large pieces of material into smaller pieces or fine powder that meet the required specifications.

·Classification:

· Jaw Crusher - PE

· Hammer Crusher - PC

· Spring Cone Crusher - PYB / PYZ / PYD

· Single-Cylinder Hydraulic Cone Crusher - PYY

03Ball Mill

BackWorking Principle: The mill rotates slowly via a transmission device. Material is fed from the feed end into the cylinder. Inside the cylinder, the material is crushed due to the impact and self-grinding action of the grinding media (steel balls, steel rods, or the ore itself). The continuous feeding of material creates pressure that pushes the material from the feed end towards the discharge end. Material that reaches the desired particle size is discharged from the discharge end of the cylinder.

· Mill Classification Based on Different Criteria:

· By Media: Ball Mill, Rod Mill, Autogenous Mill (AG Mill).

· By Process Operation: Dry Grinding, Wet Grinding.

· By Discharge Method: Grate Discharge, Overflow Discharge.

· Specific Models:

· Wet Energy-saving Grate Ball Mill - MQGg

· Wet Grate Ball Mill - MQG

· Straight Cylinder Energy-saving Overflow Ball Mill - MQYg

· Wet Overflow Ball Mill - MQY

· Dry Rod Mill - MBS

· Dry Ball Mill - Ф900×1800

· Wet Rod Mill - MBY

04Flotation Machine

BackWorking Principle: When the impeller rotates, the slurry in the impeller chamber is thrown outwards by centrifugal force, creating a negative pressure area within the impeller chamber. Air is drawn through the air intake pipe and central cylinder into the impeller chamber, where it mixes with the sucked-in slurry, forming numerous fine bubbles. After being stabilized by the disperser hood, these bubbles disperse evenly throughout the tank, forming mineralized bubbles. The mineralized bubbles rise to the froth layer and are scraped off by scrapers as the froth product (concentrate).

· Model Classification:

· XCF Forced Air Flotation Machine

· KYF Forced Air Flotation Machine

· SF Mechanical Agitation Flotation Machine

· JJF Mechanical Agitation Flotation Machine

· BF Mechanical Agitation Flotation Machine

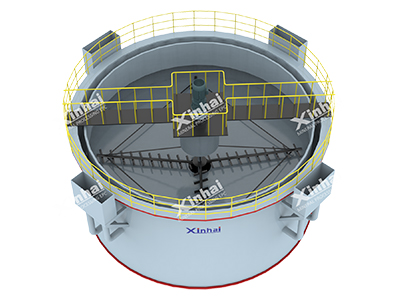

05Thickener

BackWorking Principle: Mainly consists of a circular thickening tank and a rake scraper mechanism. Solid particles suspended in the slurry settle under gravity within the thickening tank, while the upper layer becomes clarified water, achieving solid-liquid separation. The settled sludge at the bottom of the tank is continuously raked towards the central discharge port by the rake mechanism, while the clarified water overflows from the top rim of the tank.

· Model Classification:

· High-Efficiency Deep Cone Thickener - GSNG

· High-Efficiency Modified Thickener - NZSG

· High-Efficiency Thickener - GX

· Inclined Plate Thickener - ZQN

06Conclusion

BackEfficient ore processing depends on the appropriate combination of equipment.

· Crushing and grinding equipment prepare the ore for further processing.

· Gravity separation equipment provides a low-cost solution for coarse stibnite/ore.

· Flotation equipment ensures high recovery of fine and complex ores.

· Auxiliary systems maintain smooth operation and concentrate quality.

· For most operations, a combined gravity + flotation flowsheet offers the best balance of efficiency, cost, and recovery.

· Careful equipment selection, supported by ore testing and pilot studies, remains key to successful mineral processing.

+86 182 3440 3483

+86 182 3440 3483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now