7 Key Steps in the Antimony Beneficiation Process

Laura

Laura

Dec 29, 2025

Dec 29, 2025

257

257

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

antimony mine pic

Antimony is a critical metalloid widely used in flame retardants, alloys, batteries, semiconductors, and chemical applications. With increasing global demand and declining high-grade ore reserves, efficient antimony beneficiation processes are essential to maximize recovery and improve concentrate quality.

This article outlines the 7 key steps in the antimony beneficiation process, explaining how raw antimony ore is transformed into a high-grade concentrate suitable for smelting and downstream applications.

Summary of the 7 Key Steps:

1. Ore crushing

2. Grinding and classification

3. Washing and desliming

4. Gravity separation

5. Flotation beneficiation

6. Concentrate dewatering and drying

7. Tailings treatment and environmental management

01 Antimony Ore Crushing

BackThe first step in the antimony beneficiation process is crushing, which reduces large ore blocks into smaller, manageable sizes.

Purpose of Crushing:

Liberate antimony minerals from gangue

Prepare ore for grinding and classification

Improve processing efficiency

Common Equipment:

Jaw crushers

Cone crushers

Impact crushers

Crushing is usually performed in multiple stages (primary and secondary) to achieve optimal particle size reduction without excessive fines.

02 Grinding and Classification

BackAfter crushing, the ore undergoes grinding to further liberate antimony-bearing minerals such as stibnite (Sb₂S₃).

Key Objectives:

Achieve sufficient mineral liberation

Control particle size for downstream separation

Prevent over-grinding, which can reduce recovery

Typical Equipment:

Ball mills

Rod mills

Hydrocyclones or spiral classifiers

Proper grinding fineness is critical, as antimony minerals are often fine-grained and closely associated with quartz, calcite, or sulfide minerals.

One-Stage Closed Circuit Grinding System

03 Antimony Ore Washing and Desliming

BackIn many antimony deposits, clay, slime, and fine impurities interfere with separation efficiency. Ore washing and desliming help remove these unwanted materials.

Benefits:

Improves flotation or gravity separation performance

Reduces reagent consumption

Enhances concentrate grade

This step is particularly important for oxidized or weathered antimony ores.

04 Gravity Separation

BackGravity separation is one of the most commonly used techniques in antimony beneficiation due to the relatively high density of antimony minerals.

Suitable Methods:

Jigging

Shaking tables

Spiral concentrators

Advantages:

Low operating cost

Environmentally friendly

Effective for coarse-grained antimony ores

Gravity separation is often used as a pre-concentration step to discard waste rock before flotation.

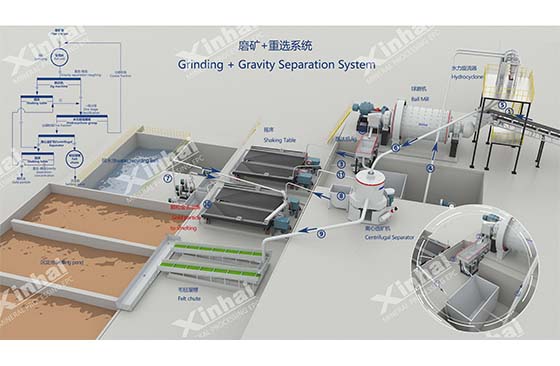

Grinding + Gravity Separation System

05 Antimony Flotation Process

BackFor fine-grained or complex antimony ores, froth flotation is the most effective beneficiation method.

Flotation Process Overview:

Collectors selectively attach to antimony minerals

Frothers stabilize air bubbles

Depressants suppress unwanted minerals

Common Reagents:

Xanthates or dithiophosphates (collectors)

Pine oil or MIBC (frothers)

Lime or sodium silicate (modifiers)

Flotation can produce high-grade antimony concentrates, especially for sulfide ores such as stibnite.

06 Concentrate Dewatering and Drying

BackOnce beneficiation is complete, the antimony concentrate must be dewatered and dried to prepare it for smelting or sale.

Dewatering Equipment:

Thickeners

Vacuum filters

Filter presses

Drying Methods:

Rotary dryers

Fluidized bed dryers

Effective dewatering reduces transportation costs and improves smelting efficiency.

Flotation + Concentrate Dewatering System

07 Tailings Treatment and Environmental Management

BackThe final step in the antimony beneficiation process is tailings management and environmental protection.

Key Considerations:

Safe disposal of tailings

Recovery of residual antimony

Water recycling

Compliance with environmental regulations

Modern antimony beneficiation plants increasingly adopt closed-loop water systems and tailings reprocessing to reduce environmental impact.

08Conclusion

BackThe antimony beneficiation process involves a carefully controlled sequence of operations designed to maximize recovery and product quality. From crushing and grinding to flotation and tailings management, each step plays a vital role in producing market-ready antimony concentrate.

By optimizing each stage, mining operations can significantly improve antimony recovery rates, reduce costs, and meet growing global demand.

+86 182 3440 3483

+86 182 3440 3483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now