How Is Gold Extracted from Its Ore? A Simple Guide to the Process

Laura

Laura

Jul 29, 2025

Jul 29, 2025

666

666

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

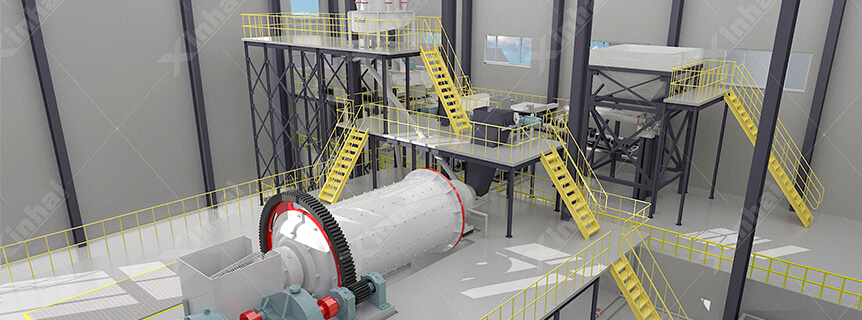

( 1200tpd gold mine project 3D renderings )

Gold has fascinated humanity for millennia, but turning raw ore into gleaming bullion requires a blend of ancient techniques and cutting-edge science. Whether it's hidden in quartz veins or scattered as microscopic particles, extracting gold demands precision, chemistry, and engineering. In this guide, we'll break down the journey from rock to refined gold—no jargon, just clarity.

01Why Is Gold Extraction So Complex?

BackGold rarely exists in pure form underground. It's often locked inside minerals like pyrite or mixed with sand, clay, and other metals. The extraction process must:

Liberate gold particles from surrounding rock.

Concentrate the gold to make processing efficient.

Safeguard the environment from toxic byproducts like cyanide.

02Step 1: Mining the Ore

BackGold ore is mined using two primary methods:

Open-Pit Mining: For near-surface deposits, giant excavators dig vast pits.

Underground Mining: For deeper veins, tunnels and shafts access the ore.

03Step 2: Crushing and Grinding

BackCrushing: Jaw crushers and cone crushers break ore into walnut-sized chunks.

Grinding: Ball mills pulverize the chunks into a fine powder, freeing gold particles for the next steps.

04Step 3: Beneficiation – Concentrating the Gold

BackBefore chemical processing, the ore is "upgraded" to remove waste:

Gravity Separation:

Sluice Boxes: Water washes lighter materials away, leaving dense gold behind.

Centrifuges: Spin ore slurry at high speeds to isolate gold.

Froth Flotation:

Chemicals make gold particles stick to air bubbles, which rise to the surface as froth.

Used for ores where gold is bound to sulfide minerals.

05Step 4: Chemical Extraction – Cyanide Leaching

BackOver 90% of gold mines use cyanide to dissolve gold:

Leaching Tanks: Ore is mixed with a diluted cyanide solution (NaCN or KCN).

Reaction: Cyanide binds to gold, forming a soluble gold-cyanide compound.

Separation: The gold-rich solution is drained from the waste (now called tailings).

Safety Note: Modern plants neutralize cyanide waste using hydrogen peroxide or natural degradation.

06Step 5: Gold Recovery

BackCarbon Adsorption: Activated carbon filters absorb gold from the cyanide solution.

Electrowinning: An electric current plates gold onto steel wool cathodes.

Smelting: The gold concentrate is melted at 1,064°C (1,947°F) to remove impurities, forming doré bars (90–95% pure gold).

07Environmental and Safety Measures

BackTailings Dams: Store toxic waste in lined ponds to prevent groundwater contamination.

Cyanide Alternatives: Some mines use non-toxic thiosulfate or bioleaching with bacteria.

Water Recycling: Closed-loop systems reuse 80–90% of water.

08Innovations in Gold Extraction

BackBioleaching: Bacteria like Acidithiobacillus dissolve gold from sulfide ores naturally.

Sensor-Based Sorting: AI and X-rays identify high-grade ore before crushing, reducing waste.

Plasma Technology: Experimental methods vaporize ore to separate gold instantly.

09FAQs

BackQ: Can gold be extracted without cyanide?

A: Sure! There is CNLITE for sodium cyanide substitute.

Q: How much gold is in one ton of ore?

A: Economically viable ore contains 0.5–5 grams of gold per ton.

Q: What happens to leftover rock?

A: Tailings are stored in secure facilities; some are repurposed for construction.

10Conclusion

BackExtracting gold from ore is a dance of physics, chemistry, and environmental stewardship. From crushing rocks to smelting bars, each step ensures this precious metal meets the world's demand for jewelry, electronics, and investments. While challenges like cyanide use and waste persist, innovations in bioleaching and recycling are paving the way for greener gold. Next time you hold a gold coin, remember the incredible journey it took from Earth's crust to your hand.

Feel free to contact us and learn more about gold processing solutions!

+86 183 3575 8886

+86 183 3575 8886 pinklaurabao@gmail.com

pinklaurabao@gmail.com

Message

Message Chat Now

Chat Now