A Complete Guide to Gold Flotation Process

Laura

Laura

Oct 07, 2025

Oct 07, 2025

923

923

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

1000tpd flotation plant in a gold mine in Laos

Gold flotation is one of the most effective and widely used methods for separating gold from ore in the mining industry. This process is an essential part of the gold beneficiation process, which is aimed at extracting gold in its purest form while ensuring the least amount of waste material. In this guide, we’ll explain what gold flotation is, how it works, and why it’s a crucial step in gold mining operations.

01 What Is Gold Flotation?

BackGold flotation refers to the method of separating gold from other minerals in an ore using a chemical treatment that exploits the difference in surface properties between gold particles and unwanted gangue minerals. The flotation process involves adding specific chemicals to the ore slurry (a mixture of water and ground ore) to create bubbles that selectively attach to gold particles, allowing them to rise to the surface and be skimmed off.

In simple terms, gold flotation makes use of the ability to separate hydrophobic (water-repelling) minerals, like gold, from hydrophilic (water-attracting) minerals, which do not react with the chemicals used. The gold particles attach to the bubbles created by the flotation reagents, while the waste material, or gangue, sinks to the bottom of the flotation cell.

02 The Gold Flotation Process: Step-by-Step

Back1. Crushing and Grinding:

Before the flotation process can begin, the gold ore must be crushed and ground into smaller particles. This allows for better exposure of the gold contained in the ore, making it more accessible for flotation.

2. Adding Reagents:

After the ore is ground into fine particles, the slurry is mixed with various flotation reagents. These chemicals are crucial for creating the conditions necessary for flotation to occur. Common reagents include collectors, frothers, and activators:

Collectors: These chemicals increase the hydrophobicity of the gold particles, helping them bond to the air bubbles.

Frothers: Frothers are responsible for creating stable bubbles in the flotation cell.

Activators: Activators are used to enhance the interaction between the gold particles and the collectors.

3. Flotation in Cells:

The slurry is then transferred to flotation cells, where air is pumped into the mixture. The reagents cause the gold particles to attach to the air bubbles. As the bubbles rise to the surface, they carry the gold with them.

4. Skimming Off the Froth:

As the bubbles reach the surface, a froth forms, which is rich in gold particles. The froth is skimmed off the top of the flotation cell, while the remaining gangue material sinks to the bottom.

5. Gold Concentration:

The froth is then further processed to concentrate the gold. Sometimes, the concentrate is reprocessed using additional flotation or other methods like cyanidation to achieve higher purity gold.

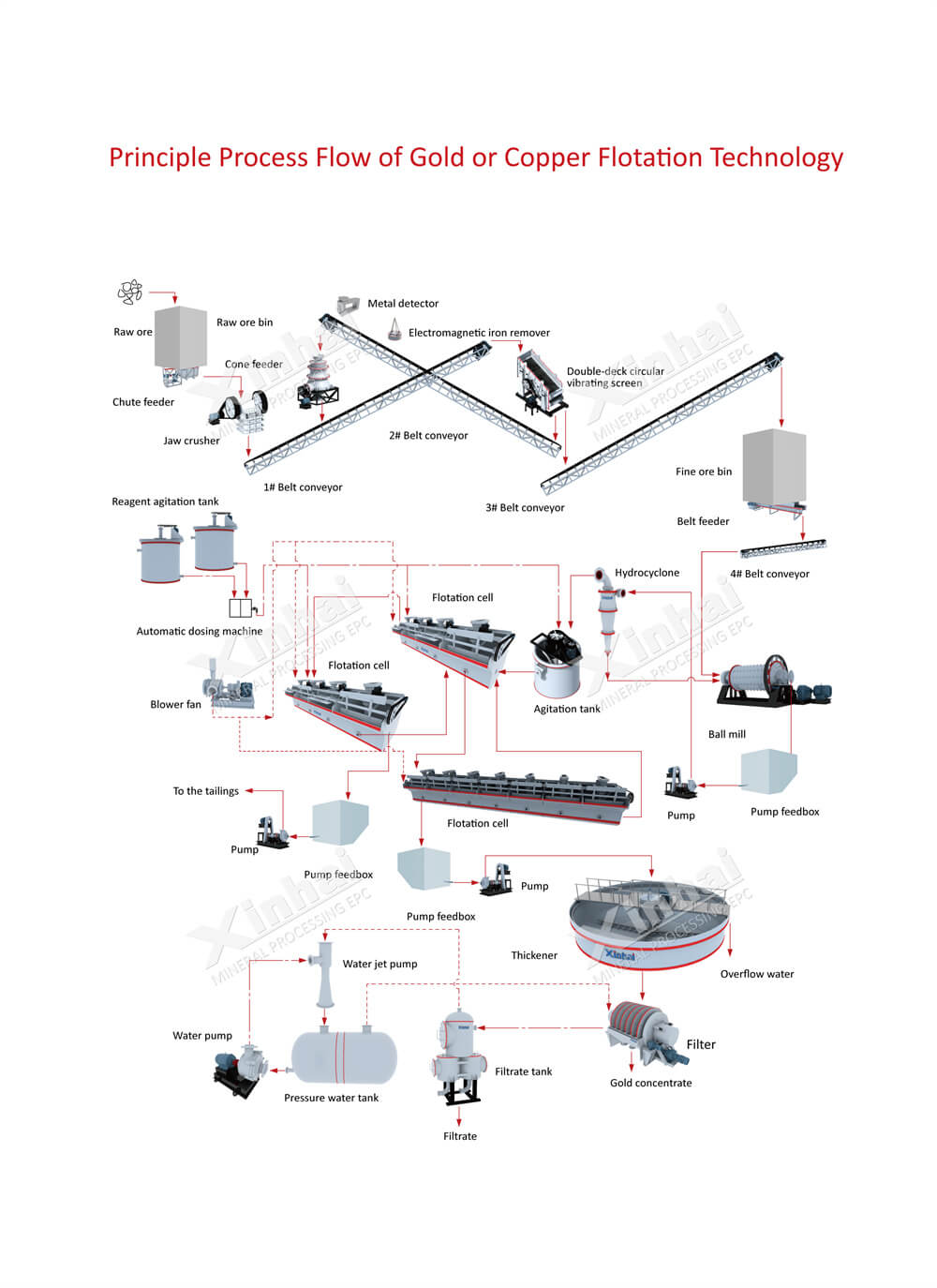

principle process flow of gold or copper flotation technology

03 Benefits of Gold Flotation

BackHigh Recovery Rates: One of the primary advantages of the flotation process is its ability to recover gold from low-grade ores with higher efficiency than some other extraction methods.

Cost-Effectiveness: When compared to other methods like gravity separation or cyanidation, flotation is often more cost-effective for certain types of ore.

Environmental Benefits: Flotation requires less water than methods like cyanidation, which can be important in areas with limited water supply.

04 Gold Flotation vs. Other Gold Extraction Methods

BackWhile gold flotation is effective for certain types of ore, it is not suitable for all gold-bearing materials. Here’s how it compares to other popular gold extraction methods:

Gravity Separation: Gravity separation is a simple method used to separate gold based on its density. However, it is most effective for high-grade gold ores and cannot be used for fine gold or ores with low gold content.

Cyanidation: Cyanide is a highly effective method for extracting gold from ore, but it is expensive and potentially harmful to the environment. The flotation method is often used before cyanidation to concentrate gold before cyanide leaching.

Amalgamation: This process uses mercury to extract gold, but it is less commonly used today due to environmental concerns and the toxicity of mercury.

05 Factors That Affect Gold Flotation Efficiency

BackSeveral factors can influence the efficiency of the gold flotation process:

Ore Composition: The mineral composition of the ore plays a critical role. Gold ores with a high concentration of pyrite or other sulfide minerals tend to be more amenable to flotation.

Particle Size: The finer the gold particles, the more difficult it is for flotation to separate them effectively. Proper grinding and particle size control are essential.

Reagent Selection: The type and dosage of reagents used in the flotation process directly affect the recovery rate. Optimizing reagent chemistry is key to maximizing gold yield.

Flotation Cell Design: The design of flotation cells, including the size and shape of the cells, the amount of air supplied, and the speed of agitation, can all impact flotation performance.

06 Challenges in Gold Flotation

BackDespite its effectiveness, gold flotation does come with its challenges:

Fine Gold Loss: Very fine gold particles can be difficult to recover using flotation and may end up in the tailings.

Reagent Costs: The chemicals required for flotation can be costly, especially for large-scale operations.

Environmental Concerns: Some flotation reagents can be harmful to the environment if not properly managed.

07 Conclusion

BackGold flotation is an essential part of the beneficiation process, particularly for ores with low to medium gold content. By using a combination of reagents and flotation technology, gold can be selectively separated from other minerals and concentrated for further processing. While it offers numerous benefits such as high recovery rates and cost-efficiency, it’s important for mining companies to optimize the process to address challenges like fine gold loss and environmental impacts.

If you’re interested in exploring gold flotation for your mining operation, it’s crucial to work with experts who understand the various factors that impact flotation efficiency. With the right techniques and equipment, you can ensure that your gold extraction process is both effective and sustainable.

Feel free to contact us and learn more about gold flotation solutions!

+86 182 3440 3483

+86 182 3440 3483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now