Ball Mill Maintenance Process and Methods

Essow

Essow

Jul 18, 2023

Jul 18, 2023

5238

5238

If you want to know more details about equipment, solutions, etc, please click the button below for free consultation, or leave your requirements!

The ball mill is a common grinding equipment, widely used in industries such as mining, building materials, and chemical engineering for material grinding. The maintenance of the ball mill is of great significance in ensuring the normal operation of the equipment, extending the equipment lifespan, and improving production efficiency. This article will introduce the maintenance methods and precautions of the ball mill to help readers better maintain the ball mill.

01 Daily maintenance

Back1. Cleaning equipment

Cleaning the ball mill is one of the important tasks of daily maintenance. When cleaning, first turn off the power, remove the components such as the feed port, discharge port, and slag discharge port of the ball mill, and clean each part with clean water and detergent, being careful not to get the electrical parts wet. After cleaning, reassemble the components and check whether they are installed correctly and securely.

2. Lubricating equipment

The various parts of the ball mill need to be lubricated regularly to ensure the normal operation of the equipment. Common lubrication points include bearings, gears, and transmission devices. Generally, the lubricating oil should be changed every three months, and attention should be paid to the selection and amount of oil. If the color or clarity of the lubricating oil changes, it should be replaced immediately.

3. Checking equipment

During daily maintenance, it is also necessary to inspect the various parts of the ball mill to find problems and deal with them promptly. When inspecting, pay attention to the following aspects:

1. Check the bearings: Bearings are important components of the ball mill and need to be checked regularly. If there is wear or looseness, they should be replaced or tightened in time.

2. Check the gears: Gears are important parts of the ball mill transmission system and need to be checked for wear. If there is wear, they should be replaced in time.

3. Check the transmission system: The transmission system is the core part of the ball mill and needs to be checked for whether the connecting parts are tight and reliable. If there is looseness, they should be tightened in time.

4. Check the electrical parts: The electrical parts of the ball mill also need to be checked regularly. If problems such as worn power cords or loose connections are found, they should be dealt with promptly.

(Ball Mill Being Checked)

02 Regular maintenance

BackIn addition to daily maintenance, the ball mill also needs to undergo more comprehensive maintenance at regular intervals. Generally, the regular maintenance cycle of the ball mill is six months to one year. Regular maintenance includes the following aspects:

1. Replacement of parts

The components of the ball mill will wear out after long-term use and need to be replaced regularly. Generally, the parts that need to be replaced include bearings, gears, and transmission devices. When replacing parts, it is necessary to follow the instructions of the equipment and check whether the installed parts are correct after replacement.

2. Checking equipment

Regular maintenance also requires inspection of various parts of the ball mill to find problems and deal with them promptly. When inspecting, pay attention to the following aspects:

1. Check the grinding media

The grinding media is an important part of the ball mill for grinding ore and needs to be checked for wear. If there is wear, it should be replaced in time.

2. Check the sieve

The sieve is part of the discharge port of the ball mill and needs to be checked for whether the pore is blocked or the sieve is worn. If there is a problem, it should be replaced in time.

3. Check the feed and discharge ports

The feed and discharge ports are important parts of the ball mill and need to be checked for their sealing performance. If there is a problem, it should be dealt with promptly.

3. Cleaning equipment

Thorough cleaning of the ball mill is also required during regular maintenance. When cleaning, it is necessary to remove the components such as the feed port, discharge port, and slag discharge port of the ball mill, clean each part with clean water and detergent, and check whether the equipment has any water leakage problems.

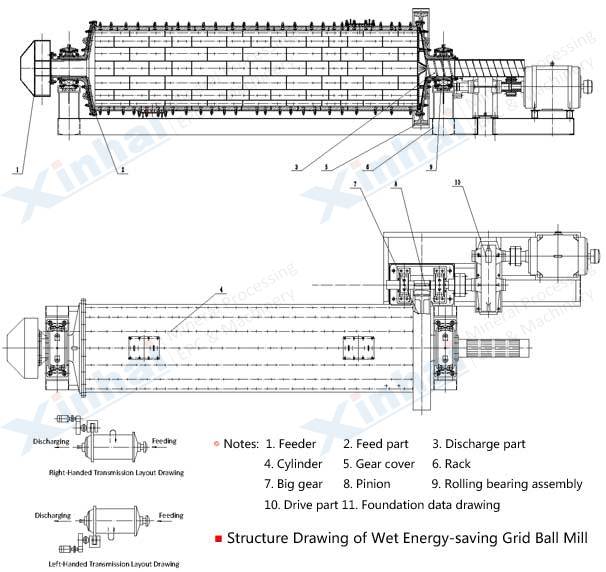

(Ball Mill Structrue)

03 Precautions

BackWhen maintaining the ball mill, the following precautions should be taken:

1. Safe operation

When maintaining the ball mill, safety operating procedures should be followed, such as turning off the power and locking the equipment. Professional tools and equipment should be used when disassembling equipment components, and personal safety should be protected.

2. Pay attention to maintenance cycle

The maintenance cycle of the ball mill needs to be adjusted according to the equipment usage and the requirements of the maintenance manual. A maintenance cycle that is too long or too short will affect the normal operation of the equipment.

3. Pay attention to maintenance quality

The maintenance quality of the ball mill directly affects the equipment lifespan and production efficiency. Therefore, it is necessary to operate carefully during maintenance to ensure that the maintenance quality meets the standard requirements.

4. Pay attention to the selection and amount of lubricating oil

The lubricating oil for the ball mill needs to be selected appropriately, and attention should be paid to the amount added. Too much or too little lubricating oil will affect the normal operation of the equipment.

Besides, if you want to know about how to install and debug ball mill, please click the link to check it.

04 Tools required for ball mill maintenance

BackWhen maintaining the ball mill, the following tools and equipment may be helpful:

1. Wrench: used to disassemble and install fastening bolts, nuts, and other components.

2. Lubricating oil gun: used to add lubricating oil to bearings, gears, transmission devices, and other parts.

3. Lubricating oil: selecting appropriate lubricating oil is crucial for ball mill maintenance.

4. Grease: used for lubrication of bearings and other parts.

5. Cleaning agent: used for cleaning various parts of the ball mill.

6. Electric hoist: used for disassembling and installing larger components, such as the grinding cylinder, gear, etc.

7. Detection instruments: used to detect the operating status of the equipment and the wear of various parts, such as vibration testers, thermometers, etc.

8. Manual lifting tools: used for disassembling and installing smaller components, such as bearings.

9. Maintenance workbench: used for equipment disassembly, maintenance, and assembly work.

10. Safety belts and ropes: used to ensure the safety of operators.

The above tools and equipment are common tools and equipment used in ball mill maintenance, which can improve maintenance efficiency and quality. However, when using these tools and equipment, it is necessary to ensure that the operators have relevant operation skills and safety awareness to ensure the safety of the operators.

05 Cost of ball mill maintenance

BackThe cost of maintaining a ball mill varies due to various factors, such as equipment model, usage time, maintenance cycle, equipment maintenance quality, etc. The following are some of the main factors that may affect the cost of maintaining a ball mill:

1. Equipment model: Different models of ball mills require different parts and lubricants, so the maintenance costs will also vary.

2. Usage time: The longer the ball mill is used, the higher the frequency of replacing parts and lubricants, and the maintenance costs will increase accordingly.

3. Maintenance cycle: Regular maintenance of the ball mill can extend the equipment lifespan and improve production efficiency, but the frequency of regular maintenance will also affect the maintenance costs.

4. Maintenance quality: Maintenance quality directly affects the equipment lifespan and production efficiency. The higher the maintenance quality, the higher the maintenance costs will be.

Based on the above factors, the cost of maintaining a ball mill is generally between several thousand yuan to tens of thousands of yuan per year. It should be noted that the maintenance cost of the ball mill is only a part of the equipment maintenance cost, and factors such as equipment purchase cost, operation cost, personnel cost, etc. also need to be considered. Therefore, a comprehensive cost analysis and management are necessary for the maintenance of the ball mill to ensure its normal operation and improve production efficiency.

06To Wrap Up

BackMaintaining the ball mill is an important part of ensuring its normal operation and improving production efficiency. Through daily and regular maintenance, the lifespan of the equipment can be extended, and the production efficiency of industries such as mining, building materials, and chemical engineering can be effectively guaranteed.

If you plan to buy a new ball mill and want to know about its price, please click the link to check it. And before buying a ball mill, you may need to know about these tips.

+86 182 3440 3483

+86 182 3440 3483 yanzhang19990421@gmail.com

yanzhang19990421@gmail.com

Message

Message Chat Now

Chat Now